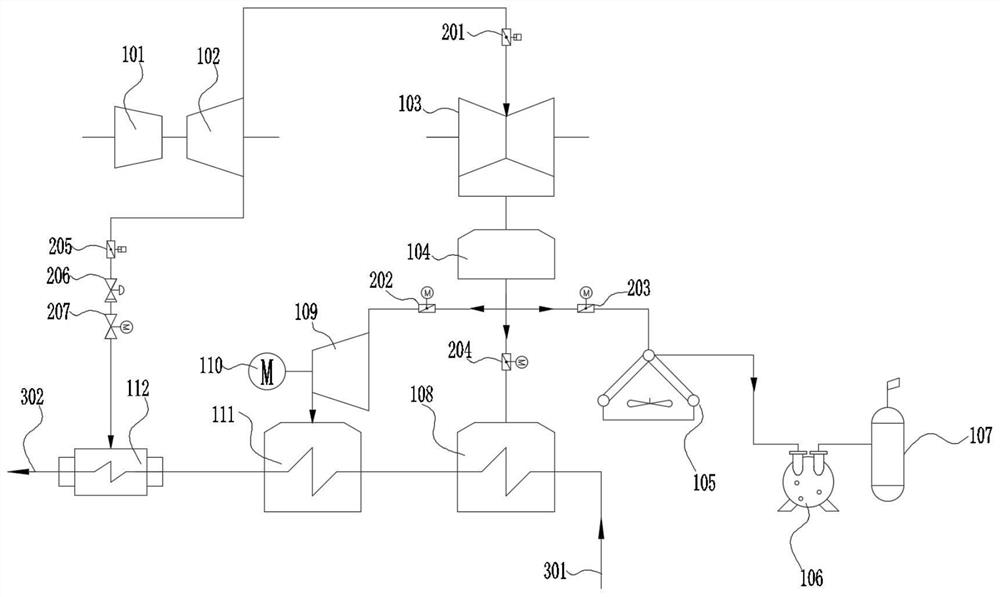

Heat supply system combining steam compressor with high-back-pressure heat supply and adjusting method

A technology for steam compressors and heating systems, which is applied in heating systems, steam engine installations, hot water central heating systems, etc., and can solve problems such as high back pressure exhausted steam that cannot be used

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

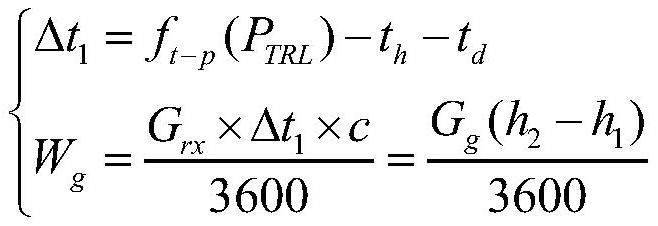

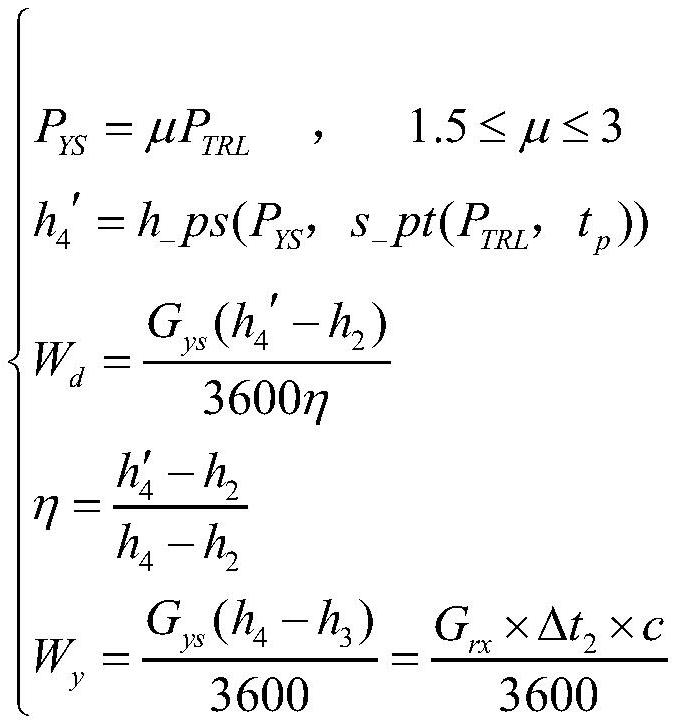

[0132] A power plant has a 300MW subcritical subcritical, intermediate reheating, double-cylinder double exhaust, direct air cooling, steam extraction and condensing unit. The unit currently bears a heat load of about 352MW, and the circulating water volume of the heating network is 8000t / h. The return water temperature 50°C, water supply temperature 88°C, high back pressure heating transformation has been carried out, the back pressure of the TRL working condition is 30kPa, the available exhaust steam is about 266t / h under the current heating condition, and there is about 65t / h high back pressure exhaust steam For the upper air cold island, about 264t / h of mid-exhaust steam extraction is needed to meet the heating load demand. Under the operating condition of 30kPa back pressure, the minimum flow rate of the low-pressure cylinder is about 350t / h, and the average power generation load during the heating period is 228MW.

[0133] Now according to the external conditions, the un...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com