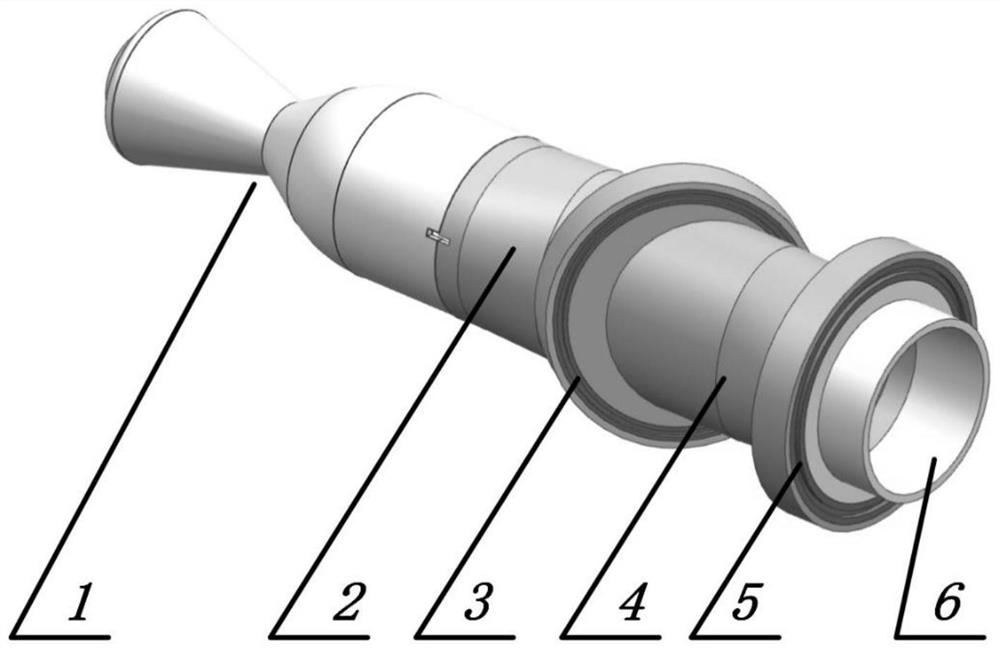

Mechanical-pneumatic composite thrust vectoring nozzle with short-distance/vertical take-off and landing functions

A vector nozzle, vertical take-off and landing technology, applied in the direction of machines/engines, jet propulsion devices, etc., can solve the problems of complex nozzle structure, difficult maintenance, difficult control, etc., to reduce the number of parts and adjust the complexity, response The effect of high speed and less mechanical structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

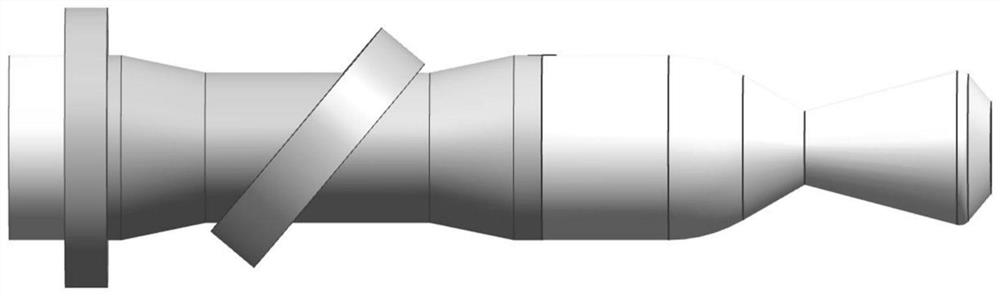

[0056] The calculation is carried out for a mechanical-pneumatic composite vectoring nozzle with vertical take-off and landing function in a typical configuration.

[0057] Figure 6 , Figure 7 What is shown is a specific embodiment of using a mechanical disturbance type throat offset type aerodynamic vectoring nozzle. in, Figure 6 Shown is the internal flow field of a nozzle with no disturbance applied near the throat. It can be seen that the present invention cannot realize the turning of the airflow beyond 95° at this time, thus vertical take-off and landing cannot be realized. But when the spoiler that controls the bowing direction is stretched out, so that the vector nozzle produces the airflow deflection in the bowing direction, the present invention obviously produces a deflection of more than 95°, specifically as Figure 7 As shown, the vertical take-off and landing function is realized. Therefore, for the present invention, it is necessary to generate a real-ti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com