Construction Technology of Asphalt Concrete Pavement Based on Target Mix Ratio

A technology of asphalt concrete and construction technology, which is applied to the cohesive pavement paved on site, roads, roads, etc., which can solve problems such as vehicle slippage, low friction on the road surface, and icing of the asphalt concrete surface, so that it is not easy to break and reduce The amount of wear and the effect of preventing cracking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

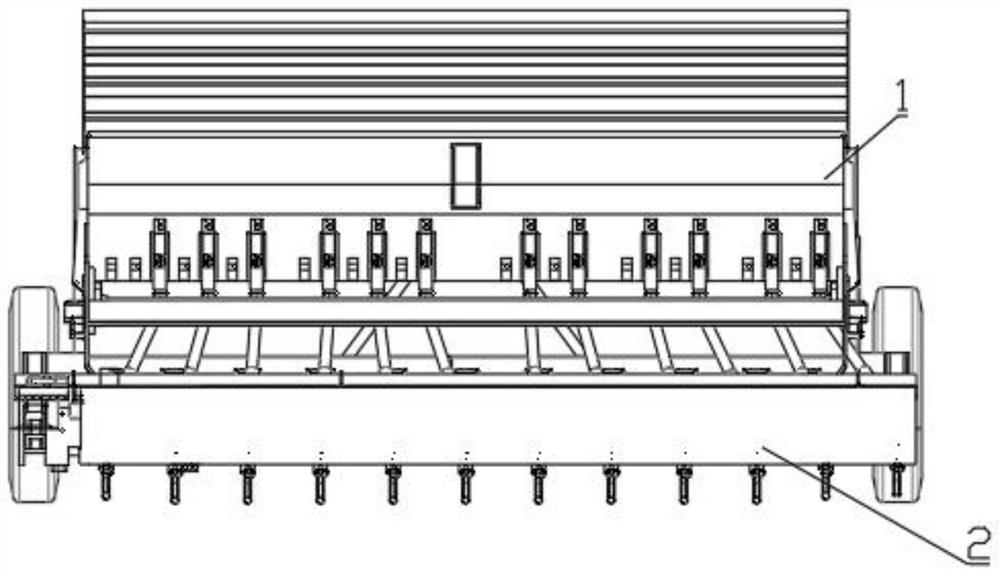

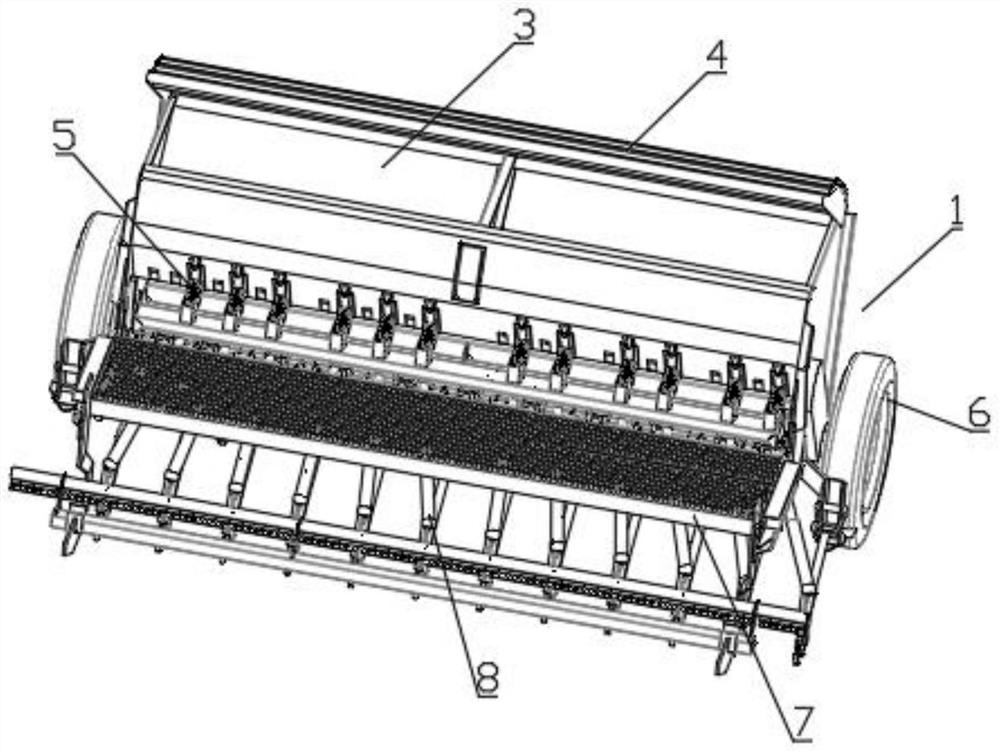

[0036] see Figure 1-6 As shown, the asphalt concrete pavement construction process based on the target mix ratio includes the following steps:

[0037] S1. Add 70 parts of basalt masterbatch; 6 parts of asphalt; 2 parts of mineral powder; 8 parts of iron tailings masterbatch; 1.5 parts of cement; 20min, get the asphalt concrete, then lay the asphalt concrete on the road surface by the paver, thereby form the asphalt concrete layer on the roadbed;

[0038] S2. Multiple rows of deformation sections are intermittently provided on the asphalt concrete layer, and each row of deformation sections is intermittently provided with multiple sets of deformation holes;

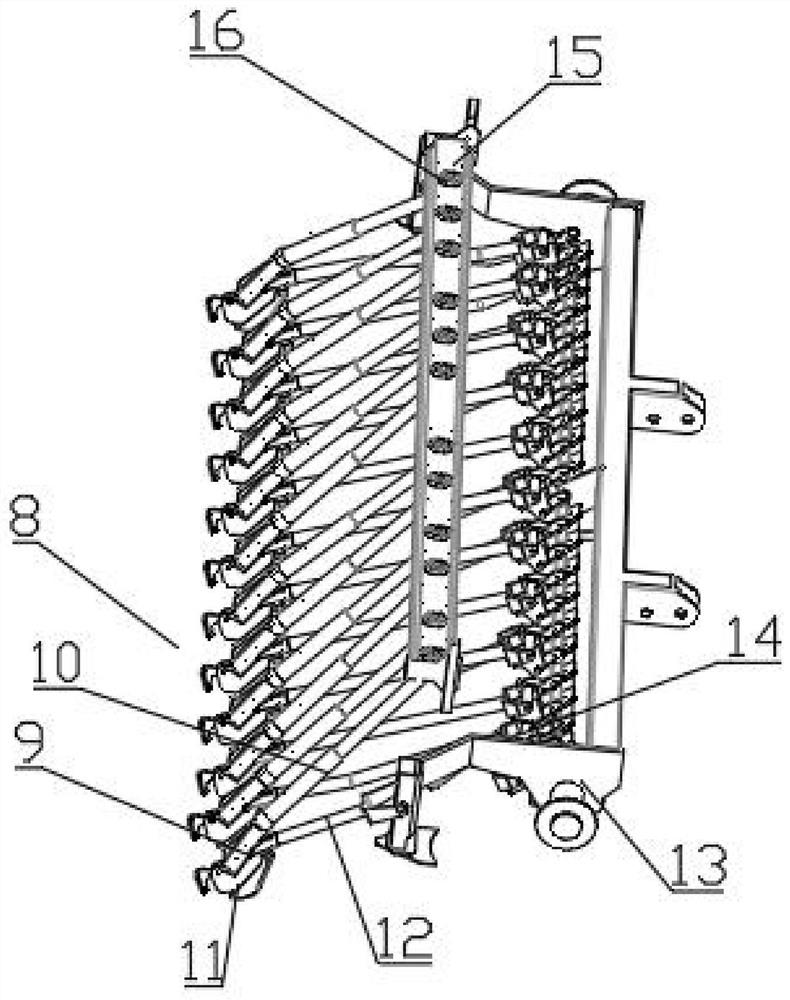

[0039] S3. Add the rubber material and the anti-wear agent to the heating chamber 3 of the melting tank 1 according to the weight ratio of 90:5 for heating, and prepare the rubber filling agent, and then according to the distance of the deformation holes on each row of deformation segments, through Spacing adjustment m...

Embodiment 2

[0042] S1. Add 80 parts of basalt masterbatch; 12 parts of asphalt; 4 parts of mineral powder; 10 parts of iron tailings masterbatch; 2.5 parts of cement; 20min, get the asphalt concrete, then lay the asphalt concrete on the road surface by the paver, thereby form the asphalt concrete layer on the roadbed;

[0043] S2. Multiple rows of deformation sections are intermittently provided on the asphalt concrete layer, and each row of deformation sections is intermittently provided with multiple sets of deformation holes;

[0044] S3. Add the rubber material and wear-resistant agent into the heating chamber 3 of the melting tank 1 according to the ratio of 100:6 by weight for heating, and prepare the rubber filling agent, and then according to the distance of the deformation holes on each row of deformation segments, pass Spacing adjustment mechanism 2 adjusts the spacing of connecting pipe 10 on the drip irrigation mechanism 8; first by controlling the forward and reverse rotation...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com