Cold-rolling annealing method of cold-rolled strip steel

A technology of cold-rolled annealing and cold-rolled strip steel, applied in heat treatment equipment, heat treatment process control, manufacturing tools, etc., can solve problems such as steel plate bonding, achieve processing cost control, enhance customer satisfaction, and enhance corporate brand image. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

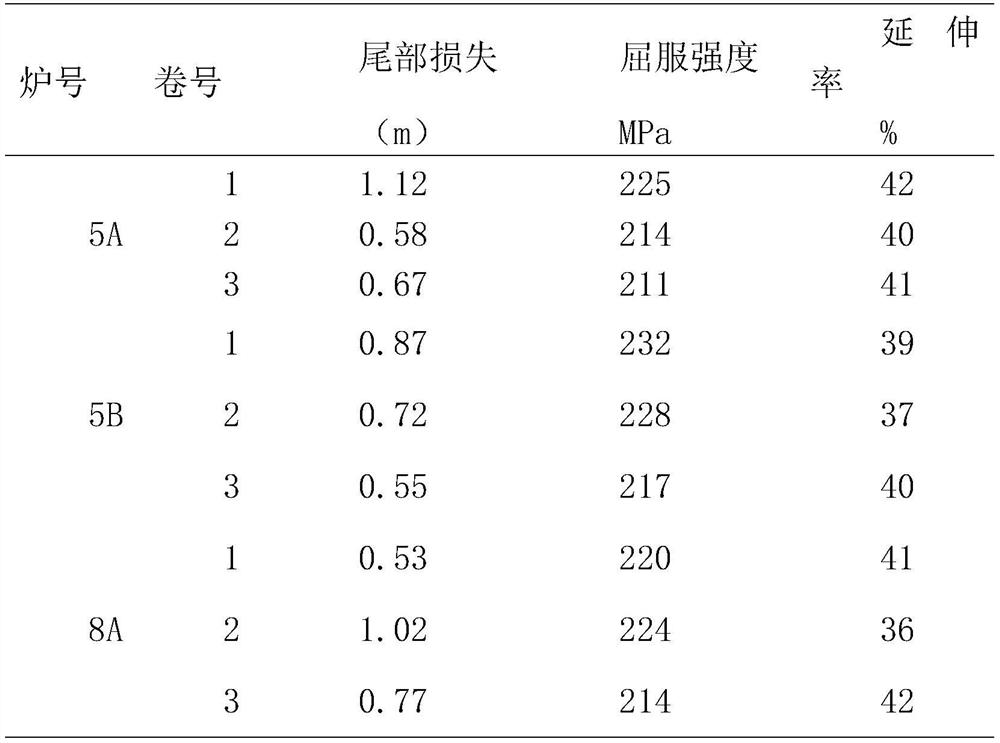

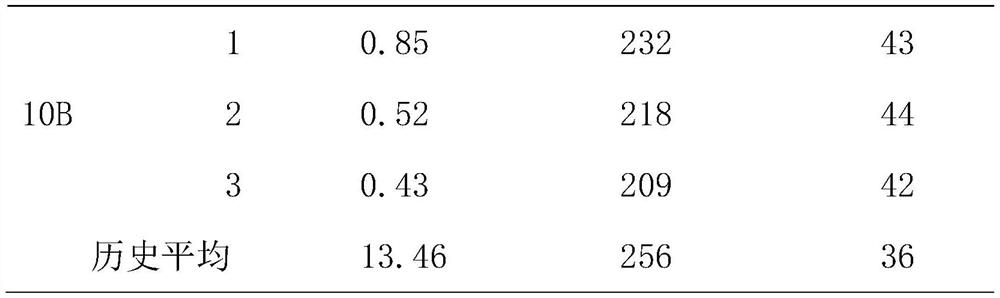

Examples

Embodiment 1

[0021] The cold-rolled annealing method of the cold-rolled steel strip in the present embodiment, comprises the following steps:

[0022] S1. Select strip steel, process the strip steel to a thickness of 2.0mm-3.5mm, then place the strip steel on the conveying mechanism, and the conveying mechanism faces the entrance of the preheating furnace, and the strip steel is sent into the preheating furnace for preheating heat, process;

[0023] S2. Heating the strip steel, transferring the preheated strip steel to the heating furnace, and changing the temperature rise rate according to the demand for heating the strip steel;

[0024] S3, heat preservation of the strip steel, the heated strip steel enters the equilibrium furnace for heat preservation, and the heat preservation time is 12h-15h;

[0025] S4, the strip steel is cooled, and the strip steel is taken out of the furnace after heat preservation for hot-line pickling. The pickling adopts a special pickling line for continuous ...

Embodiment 2

[0034] The cold-rolled annealing method of the cold-rolled steel strip in the present embodiment, comprises the following steps:

[0035] S1. Select strip steel, process the strip steel to a thickness of 2.0mm-3.5mm, then place the strip steel on the conveying mechanism, and the conveying mechanism faces the entrance of the preheating furnace, and the strip steel is sent into the preheating furnace for preheating heat, process;

[0036] S2. Heating the strip steel, transferring the preheated strip steel to the heating furnace, and changing the temperature rise rate according to the demand for heating the strip steel;

[0037] S3, heat preservation of the strip steel, the heated strip steel enters the equilibrium furnace for heat preservation, and the heat preservation time is 12h-15h;

[0038] S4, the strip steel is cooled, and the strip steel is taken out of the furnace after heat preservation for hot-line pickling. The pickling adopts a special pickling line for continuous ...

Embodiment 3

[0047] The cold-rolled annealing method of the cold-rolled steel strip in the present embodiment, comprises the following steps:

[0048] S1. Select strip steel, process the strip steel to a thickness of 2.0mm-3.5mm, then place the strip steel on the conveying mechanism, and the conveying mechanism faces the entrance of the preheating furnace, and the strip steel is sent into the preheating furnace for preheating heat, process;

[0049] S2. Heating the strip steel, transferring the preheated strip steel to the heating furnace, and changing the temperature rise rate according to the demand for heating the strip steel;

[0050] S3, heat preservation of the strip steel, the heated strip steel enters the equilibrium furnace for heat preservation, and the heat preservation time is 12h-15h;

[0051] S4, the strip steel is cooled, and the strip steel is taken out of the furnace after heat preservation for hot-line pickling. The pickling adopts a special pickling line for continuous ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com