Method for electrochemically preparing manganese dioxide-graphene compound

A manganese dioxide, electrochemical technology, applied in the field of controllable preparation of graphene-based composite materials, can solve the problems of increased production costs, large environmental hazards, high equipment requirements, etc., to achieve low cost, avoid high toxicity, and high product quality Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

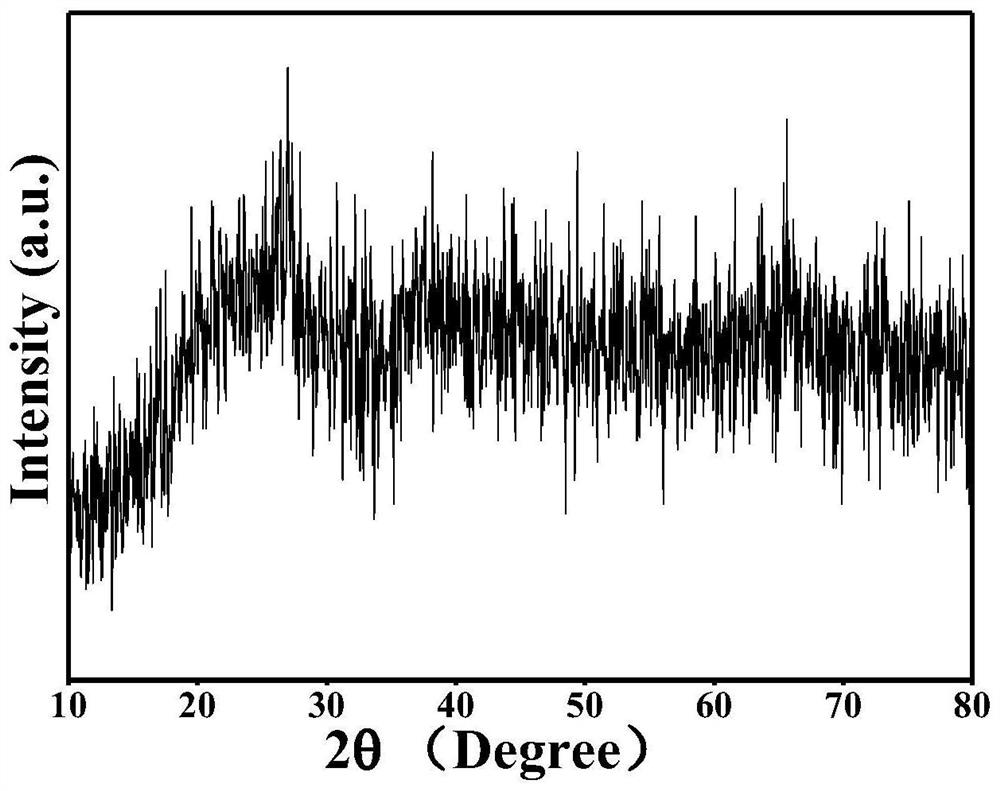

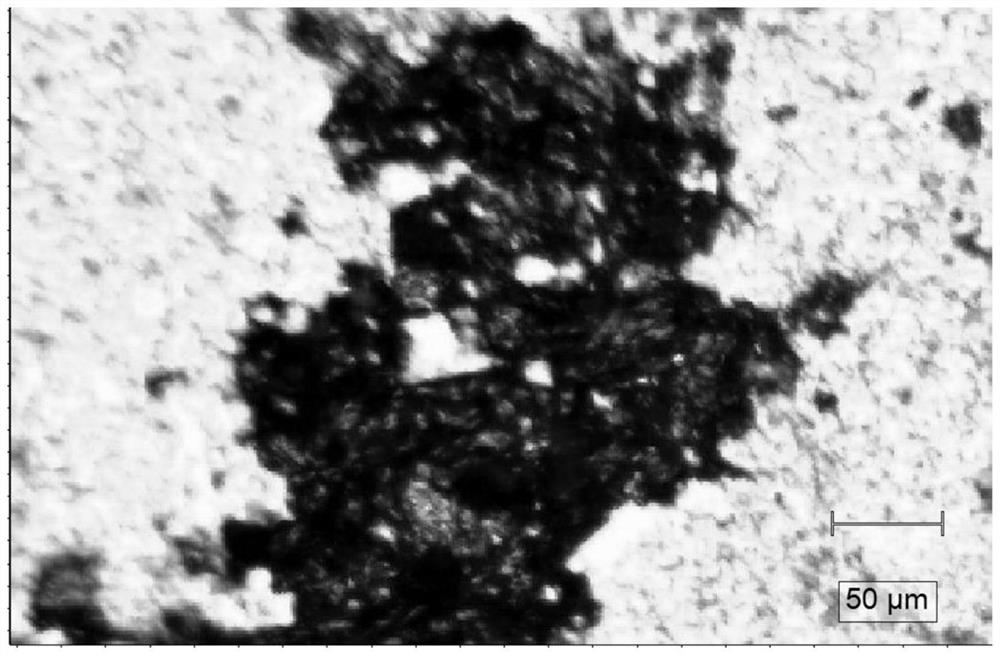

[0054] Please refer to figure 1 and figure 2 , figure 1 It is the XRD figure of electrochemically preparing manganese dioxide-graphene composite in the embodiment of the present invention, figure 2 It is an optical microscope image of the electrochemically prepared manganese dioxide-graphene composite in Example 1 of the present invention.

[0055] In this embodiment, 0.1 mol / L ammonium sulfate was used, dissolved in 300 mL of deionized water, and then 0.1 mol / L potassium permanganate was added to stir and dissolve to form an electrolyte.

[0056] Then put a graphite foil electrode with a length of 5 cm, a width of 6 cm, and a thickness of 0.2 mm into the electrolyte, and connect it to a 10V AC power supply. The positive and negative poles of the power supply are changed every 30 seconds. Hour.

[0057] Then use absolute ethanol and deionized water to carry out multiple re-washing, for example, wash 3 times.

[0058] Finally, dry in a vacuum oven at 60°C.

[0059] Util...

Embodiment 2

[0061] Please refer to image 3 and Figure 4 , figure 2 The XRD pattern of manganese dioxide-graphene composite electrochemically prepared for the embodiment of the present invention, Figure 6 The optical microscope image of the manganese dioxide-graphene composite electrochemically prepared for the embodiment of the present invention.

[0062] In this embodiment, 0.1 mol / L ammonium oxalate was used, dissolved in 300 mL of deionized water, and then 0.1 mol / L potassium manganate was added to stir and dissolve to form an electrolyte.

[0063] Then put a graphite foil electrode with a length of 5 cm, a width of 6 cm, and a thickness of 0.2 mm into the electrolyte, and connect it to a 10V AC power supply. The positive and negative poles of the power supply are changed every 30 seconds. Hour.

[0064] Then use absolute ethanol and deionized water to carry out multiple re-washing, for example, wash 3 times.

[0065] Finally, dry in a vacuum oven at 60°C.

[0066] Utilize th...

Embodiment 3

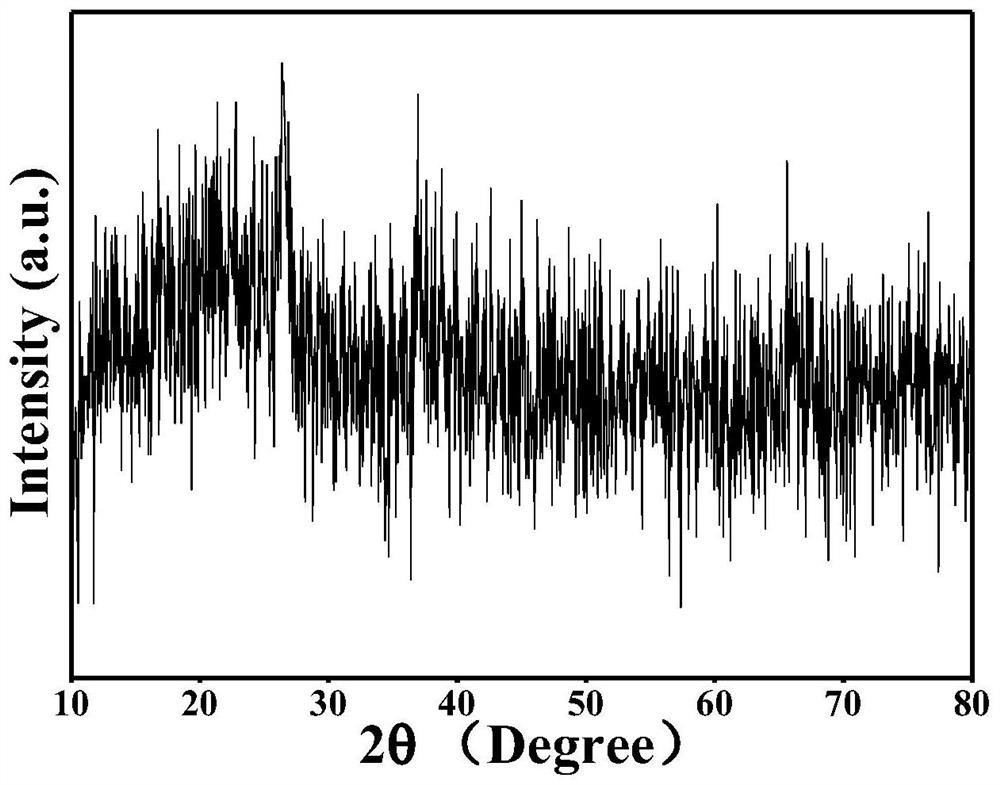

[0068] Please refer to Figure 5 and Figure 6 , Figure 5 It is the XRD pattern of electrochemically preparing manganese dioxide-graphene composite in the embodiment of the present invention three, Figure 6 It is an optical microscope image of the electrochemically prepared manganese dioxide-graphene composite in Example 3 of the present invention.

[0069] In this embodiment, 0.1 mol / L sodium chloride was used, dissolved in 300 mL of deionized water, and then 0.1 mol / L potassium permanganate was added to stir and dissolve to form an electrolyte.

[0070] Then put a graphite foil electrode with a length of 5 cm, a width of 6 cm, and a thickness of 0.2 mm into the electrolyte, and connect it to a 10V AC power supply. The positive and negative poles of the power supply are changed every 30 seconds. Hour.

[0071] Then use absolute ethanol and deionized water to carry out multiple re-washing, for example, wash 3 times.

[0072] Finally, dry in a vacuum oven at 60°C.

[00...

PUM

| Property | Measurement | Unit |

|---|---|---|

| volume | aaaaa | aaaaa |

| volume | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com