A powder spraying device for producing new energy automobile laminated glass and its application method

A technology for new energy vehicles and laminated glass, applied in spraying devices, devices for coating liquid on the surface, coatings, etc., can solve problems such as waste, powder movement, and scrapping of laminated glass, so as to prevent waste and improve powder spraying quality effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

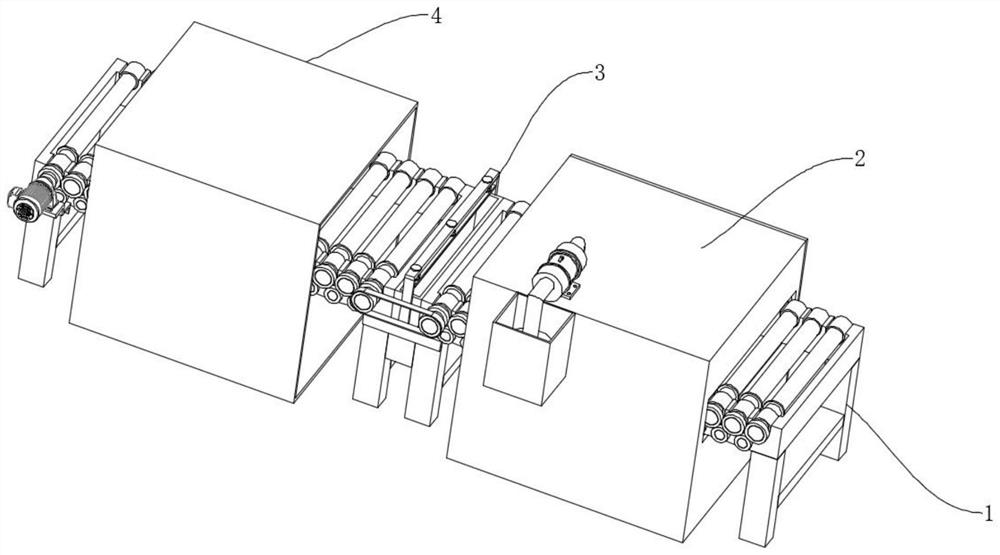

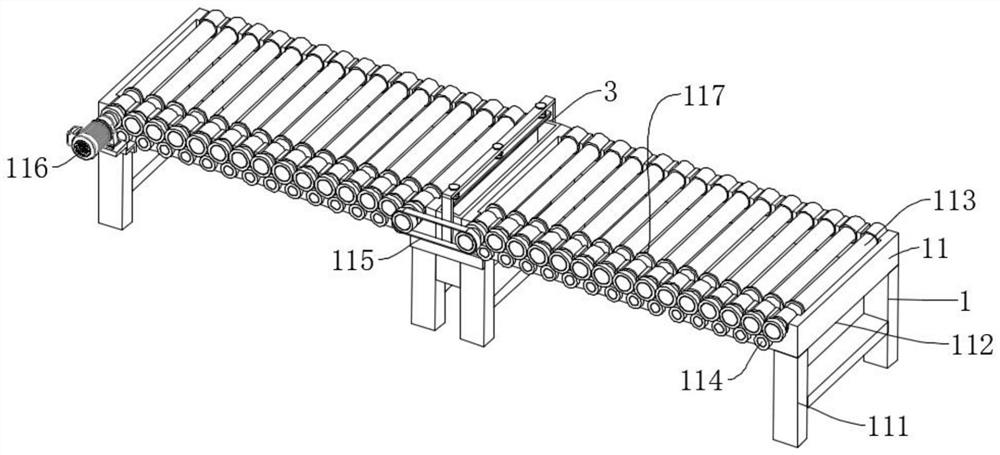

[0041] Such as figure 1 , figure 2 , image 3 , Figure 4 , Image 6 , Figure 7 , Figure 8 with Figure 9 As shown, a powder spraying device for the production of laminated glass for new energy vehicles includes a spraying mechanism 2, a drying mechanism body 4, and a transmission mechanism 1. The transmission mechanism 1 is mainly composed of two transmission components 11, and the two transmission components 11 There is a scraping mechanism 3 between them, and the transmission assembly 11 includes a support frame 111, a fixed frame 112, a transmission roller 113, a drive shaft 114, a belt 115, and a transmission motor 116. The top of the support frame 111 is connected with a fixed frame 112 by bolts, and the fixed frame The top of 112 is rotatably connected with several transmission rollers 113, and the front of the fixed frame 112 is rotatably connected with several transmission shafts 114, every two adjacent transmission rollers 113 are connected with the transmis...

Embodiment 2

[0049] Such as Figure 5 As shown, the difference between Embodiment 2 and Embodiment 1 is that the spraying mechanism 2 includes a spraying box 201, a horizontal plate 202, a partition plate 203, a first collection box 205, a spraying assembly 206, a maintenance door 207, an observation window 208, The hot air blower 21, the interior of the spraying box 201 is connected with a horizontally arranged horizontal plate 202 and a vertically arranged partition plate 203 by screws, and the partition plate 203 is located above the horizontal plate 202, and there is a certain gap between the horizontal plate 202 and the horizontal plate 202 One side of the inner top of the spraying box 201 is connected with a hot air blower 21 by bolts, the other side of the inner top of the spraying box 201 is provided with a spraying assembly 206, the top of the horizontal plate 202 is provided with a first collection box 205, and the first collection box 205 is located at the top of the spraying box...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com