Preparation method of activated carbon-based ferromanganese oxide film for catalytic oxidation of NH4<+>, and activated carbon-based ferromanganese oxide film and deamination application thereof

A technology of catalytic oxidation and activated carbon, which is applied in chemical instruments and methods, oxidized water/sewage treatment, chemical/physical processes, etc., can solve the problems of low utilization rate of light energy, achieve increased production rate, shorten preparation time, and low cost Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

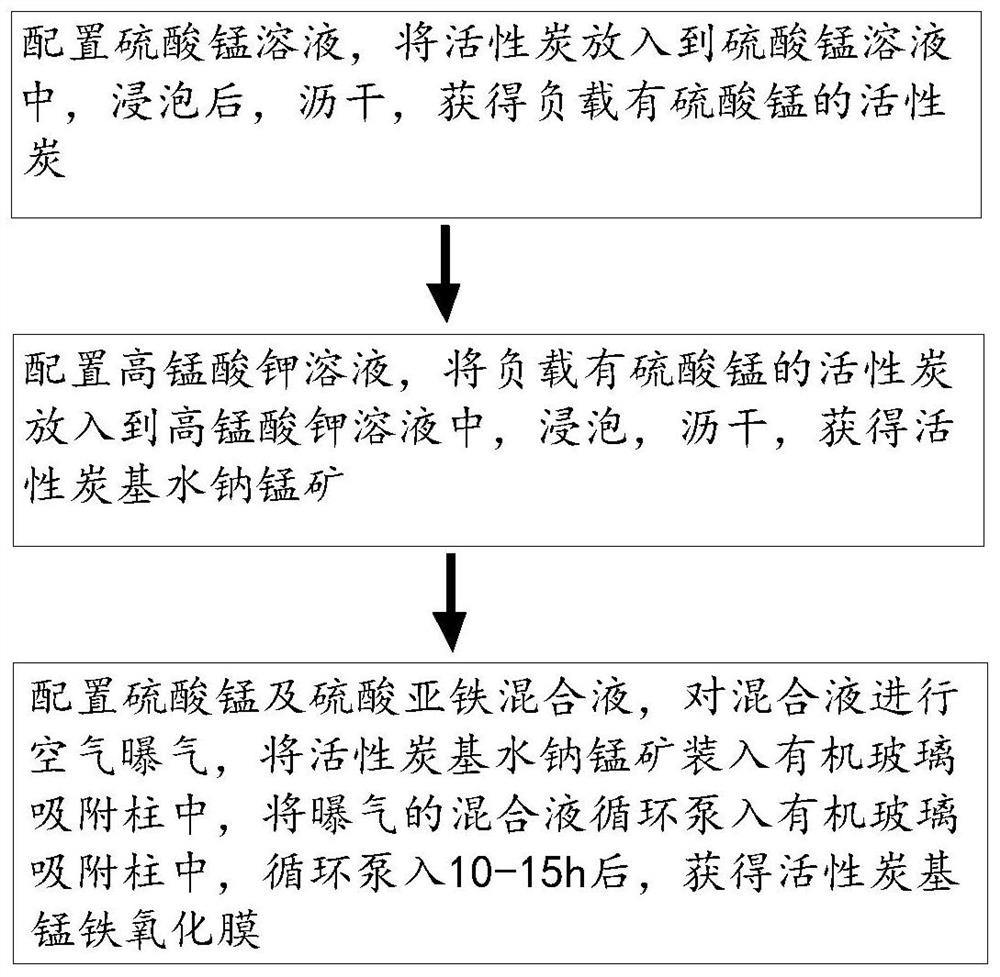

[0031] Such as figure 1 As shown, the present invention provides a method for catalytic oxidation of NH 4 + The preparation method of active carbon-based ferromanganese oxide film, comprises following preparation steps:

[0032] S1) Manganese sulfate solution is configured, activated carbon is put into the manganese sulfate solution, after soaking, drained to obtain activated carbon loaded with manganese sulfate;

[0033] S2) Potassium permanganate solution is configured, activated carbon loaded with manganese sulfate is put into the potassium permanganate solution, soaked, drained, and activated carbon-based birnessite (C / Mn-O) is obtained;

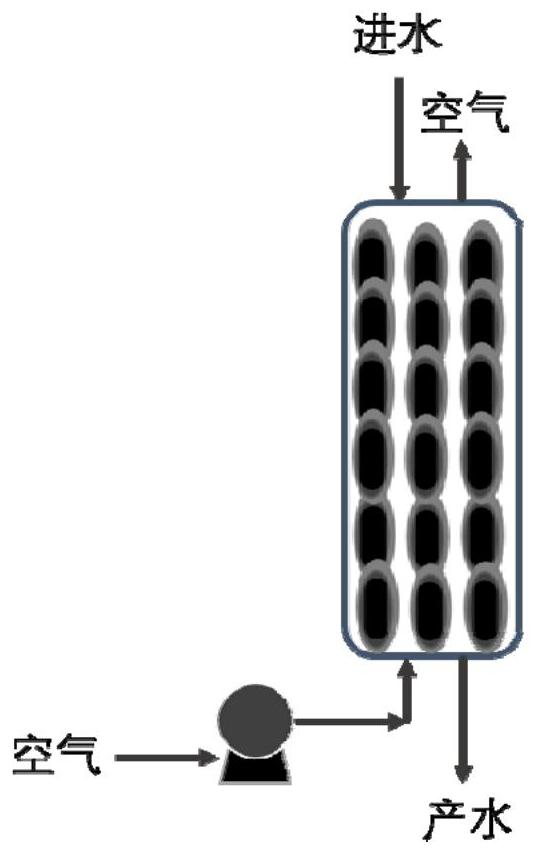

[0034] S3) Configure the mixed solution of manganese sulfate and ferrous sulfate, aerate the mixed solution with air, put activated carbon-based birnessite into the plexiglass adsorption column, pump the aerated mixed solution into the plexiglass adsorption column, and circulate After pumping for 10-15 hours, an activated carbon-based...

Embodiment 1

[0057] Sample 1 preparation:

[0058] The configuration concentration is 2L of 1mol / L manganese sulfate solution, 1kg of activated carbon is put into the manganese sulfate solution, after soaking for 1h, drain to obtain activated carbon loaded with manganese sulfate;

[0059] Configure 2L of 0.5mol / L potassium permanganate solution, put the activated carbon loaded with manganese sulfate into the potassium permanganate solution, soak for 1h, and drain to obtain activated carbon-based birnessite (C / Mn-O);

[0060] Configure Mn 2+ The mass concentration is 10g / L, Fe 2+ The mass concentration is 5g / L manganese sulfate and ferrous sulfate mixed solution 20L, the pH of the manganese sulfate and ferrous sulfate mixed solution is 7.6, the mixed solution is air aerated, and the activated carbon-based birnessite is loaded into the plexiglass adsorption column, The aerated mixed solution is circulated and pumped into the plexiglass adsorption column. The flow rate of the mixed solution...

Embodiment 2

[0067] Preparation of sample two:

[0068] The configuration concentration is 4L of 2mol / L manganese sulfate solution, 2kg of activated carbon is put into the manganese sulfate solution, after soaking for 2h, drain to obtain activated carbon loaded with manganese sulfate;

[0069] Configure 4L of 1.0mol / L potassium permanganate solution, put the activated carbon loaded with manganese sulfate into the potassium permanganate solution, soak for 2 hours, and drain to obtain activated carbon-based birnessite (C / Mn-O);

[0070] Configure Mn 2+ The mass concentration is 15g / L, Fe 2+ The mass concentration is 7.5g / L manganese sulfate and ferrous sulfate mixed solution 30L, the pH of the manganese sulfate and ferrous sulfate mixed solution is 7.6, the mixed solution is air aerated, and the activated carbon-based birnessite is loaded into the plexiglass adsorption column , the aerated mixed solution is circulated and pumped into the plexiglass adsorption column. The flow rate of the m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com