A material cutting device for a biomass fuel pellet machine

A biomass fuel and pellet machine technology, which is applied in the direction of biofuel, waste fuel, raw material extrusion pelletization, etc., can solve the problems of different lengths of biomass pellets, affecting the quality of biomass pellets, and uneven cutting effect. , to achieve a reliable fixed effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

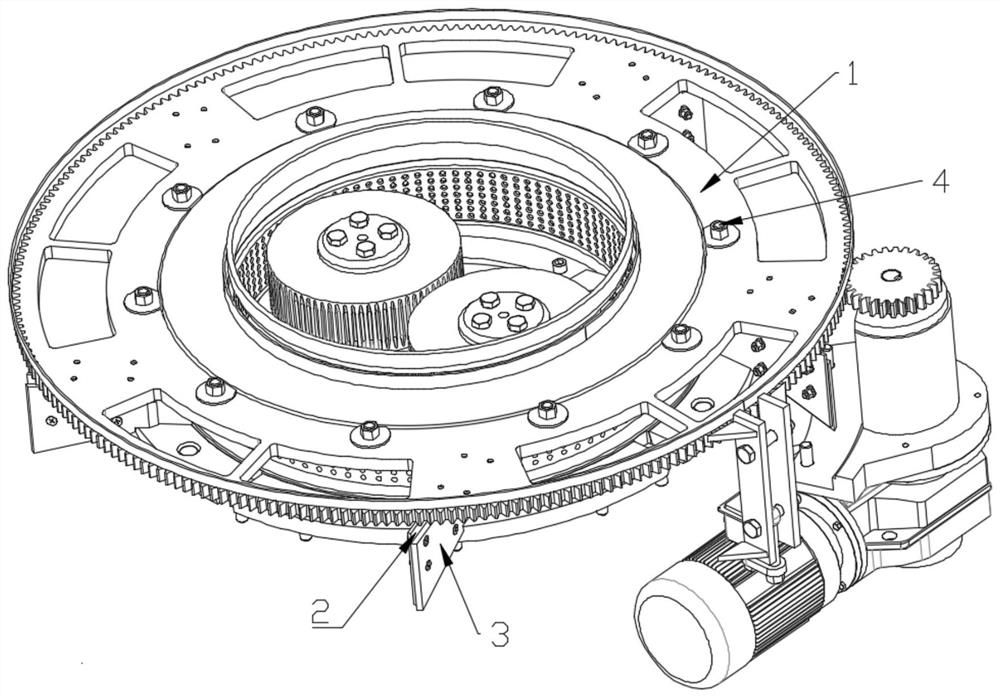

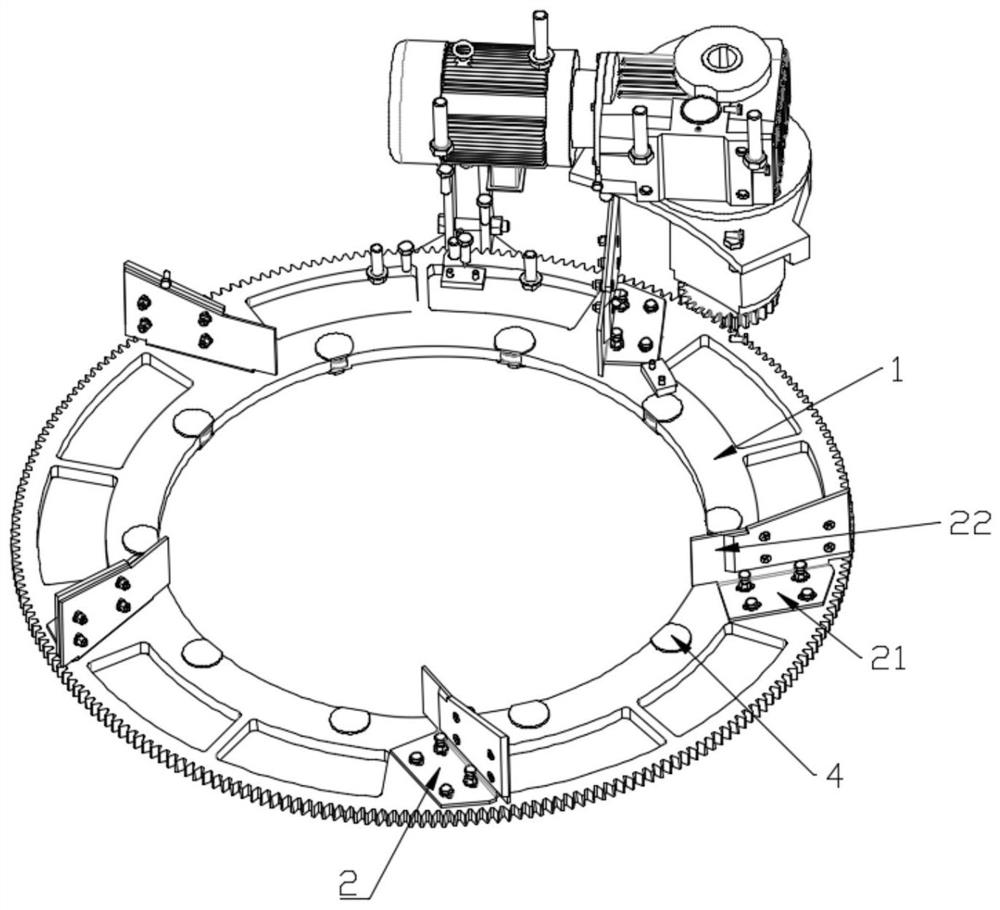

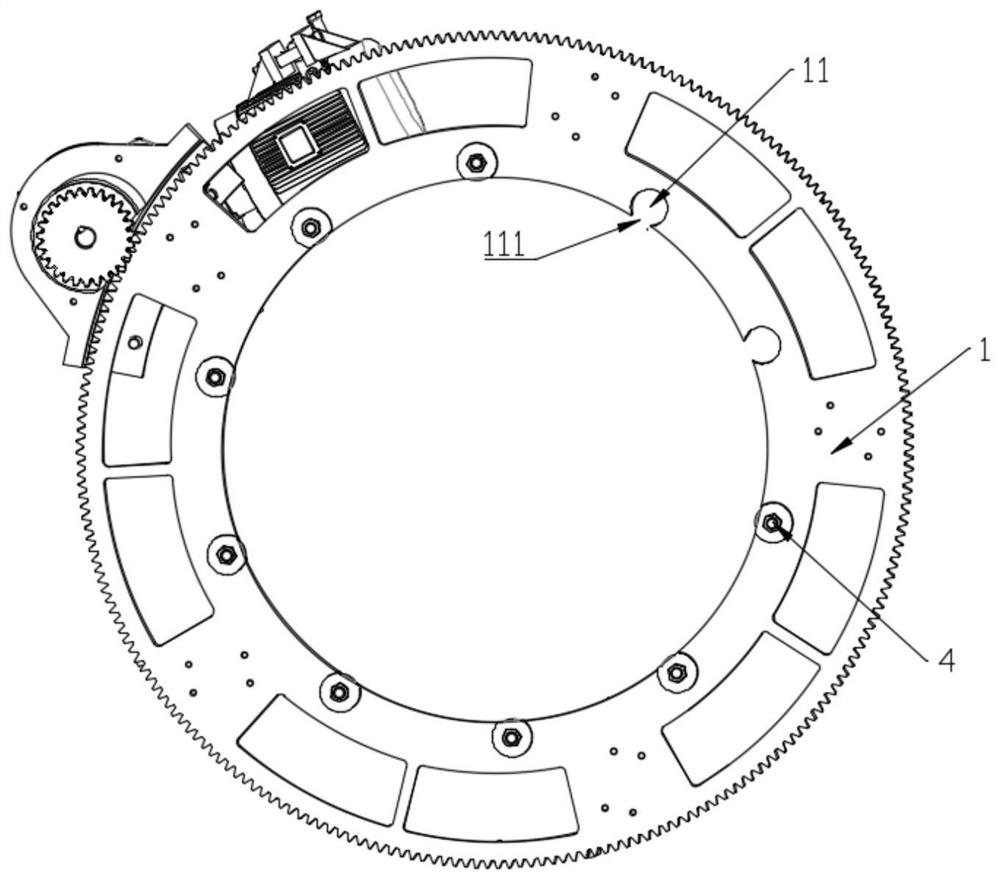

[0024] Such as Figure 1 to Figure 8 A cutting device for a biomass fuel pellet machine is shown, comprising a cutting ring gear 1 arranged coaxially with the upper edge of the ring die, several cutting knife seats 2 fixedly arranged on the lower surface of the cutting ring gear 1, a set The cutting knife 3 on the cutting knife seat 2 is equipped with a motor opposite to the cutting ring gear when in use, and a transmission gear is connected to the motor. When working, the ring die does not move, and the motor drives the cutting gear through the transmission gear. The material ring gear rotates, thereby driving the material cutting knife to rotate, cutting off the biomass particles extruded out of the ring die;

[0025] Wherein, the cutting knife seat 2 includes a horizontal plate 21 and a vertical plate 22 integrally connected, and its overall vertical section is in an inverted L shape. The cutting surface of the outer side of the mold is at a certain angle;

[0026] A numb...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com