Compact precise driving shaft system with limiting function

A drive shaft, compact technology, applied in the direction of electric components, electromechanical devices, electrical components, etc., can solve the problems of heavy weight, large size, complex structure, etc., and achieve the effect of light weight, large driving force, and high strength and rigidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

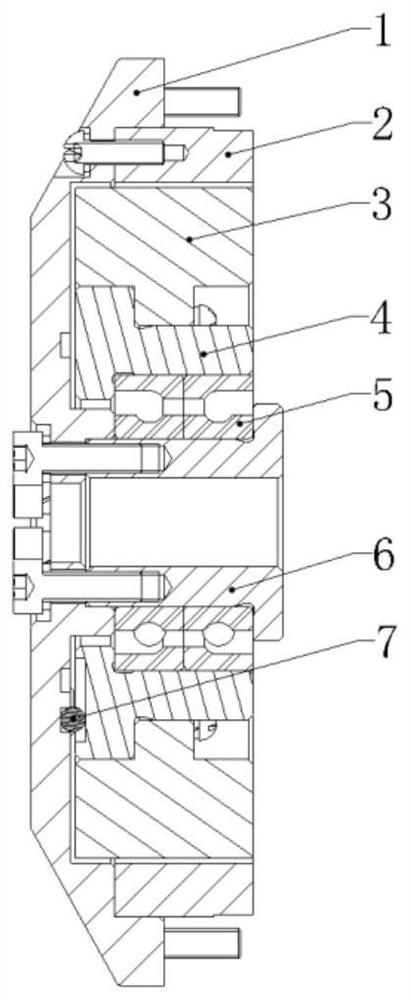

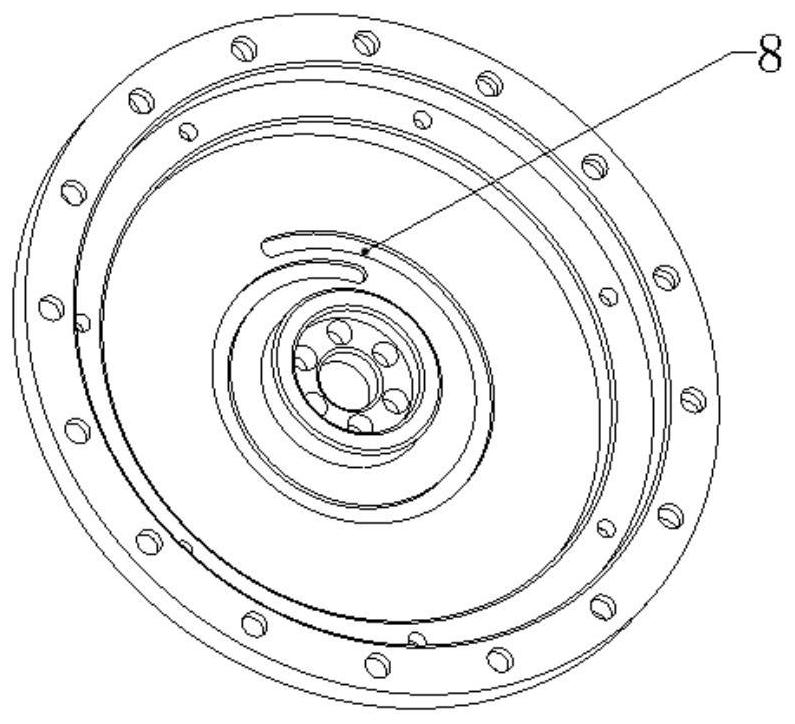

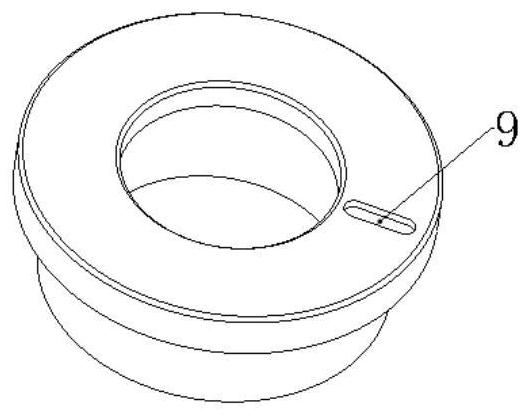

[0017] Such as figure 1 , figure 2 , image 3 As shown, the specific implementation process is as follows:

[0018] A compact precision drive shaft system with a limit, which is applied to the dual-axis indexing mechanism of the bomb-loaded three-auto inertial group, such as figure 1 As shown, the motor stator 2 and the rotating shaft 6 are respectively fixed on the motor base 1 by screws, and the inner rings of the angular contact bearing pairs 5 are fixed on the rotating shaft 6, which jointly constitute the static part of the precision drive shaft system; the angular contact bearing pairs 5 outer rings, The bearing seat 4 and the motor rotor 3 together constitute the rotating part of the precision drive shaft system. The load is fixed on the bearing seat 4 by screws and rotates with the rotating part; the steel ball 7 moves radially on the groove 9 of the bearing seat 4, and at the same time It moves along the helical groove 8 on the motor base 1 and acts as an angle li...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com