Production process of vacuum plastic-encapsulated photovoltaic modules

A photovoltaic module and production process technology, applied in photovoltaic power generation, electrical components, semiconductor devices, etc., can solve the problems of affecting the production quality of photovoltaic modules, increasing material waste, and easily damaging cells, reducing the number of lifting and transportation, and eliminating the need for Residual, ensure the effect of normal use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] Embodiment 1 A kind of vacuum plastic sealing photovoltaic module production process

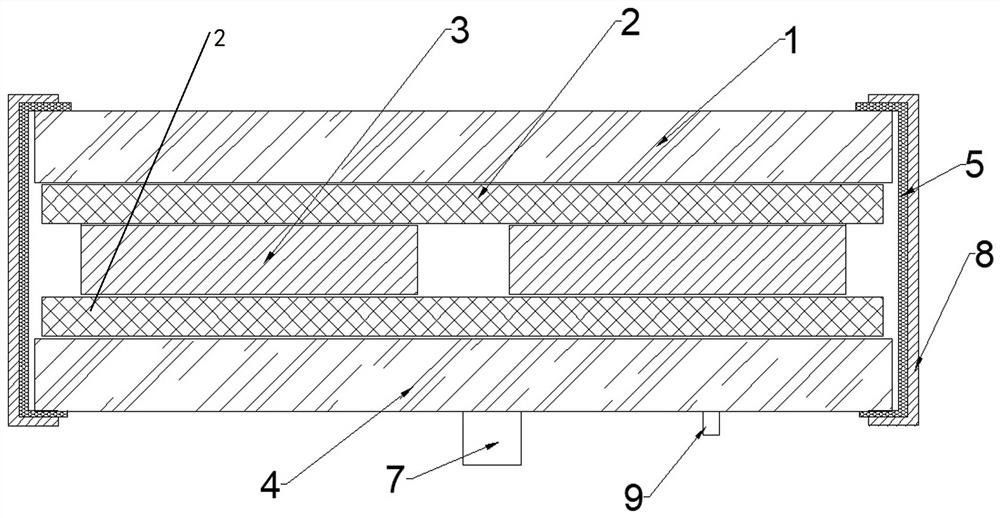

[0037] like Figure 1 to Figure 2 As shown, this embodiment includes the following steps:

[0038] S1. Lamination to form photovoltaic modules

[0039] A photovoltaic module is formed by stacking the front encapsulating material 1 , the heat-treated thermoplastic elastomer 2 , the battery string 3 , the thermally-treated thermoplastic elastomer 2 , and the back encapsulating material 4 in sequence from top to bottom.

[0040] The front encapsulation material 1 may be tempered glass, the back encapsulation material 4 may be a backplane, and both the front encapsulation material 1 and the back encapsulation material 4 may be tempered glass. Thermoplastic elastomers are selected from commonly used packaging materials for photovoltaic modules, such as EVA, POE, PVB and other materials. The thermoplastic elastomer 2 after heat treatment refers to heating the thermoplastic elastomer to 1...

Embodiment 2~6

[0052] Embodiments 2-6 A production process of vacuum plastic-sealed photovoltaic modules

[0053] The only difference between Examples 2 to 6 and Example 1 is that the parameters in the steps are different. For details, please refer to the following table:

[0054]

[0055]

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com