Fatigue test crack monitoring method and device

A fatigue test and crack technology, applied in measuring devices, using repetitive force/pulsation force to test material strength, image enhancement, etc., can solve problems such as difficulty in comprehensively evaluating the actual damage of cracks to components and difficult to meet engineering needs , to achieve the effect of retaining data accuracy and improving accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be further described below in conjunction with the accompanying drawings:

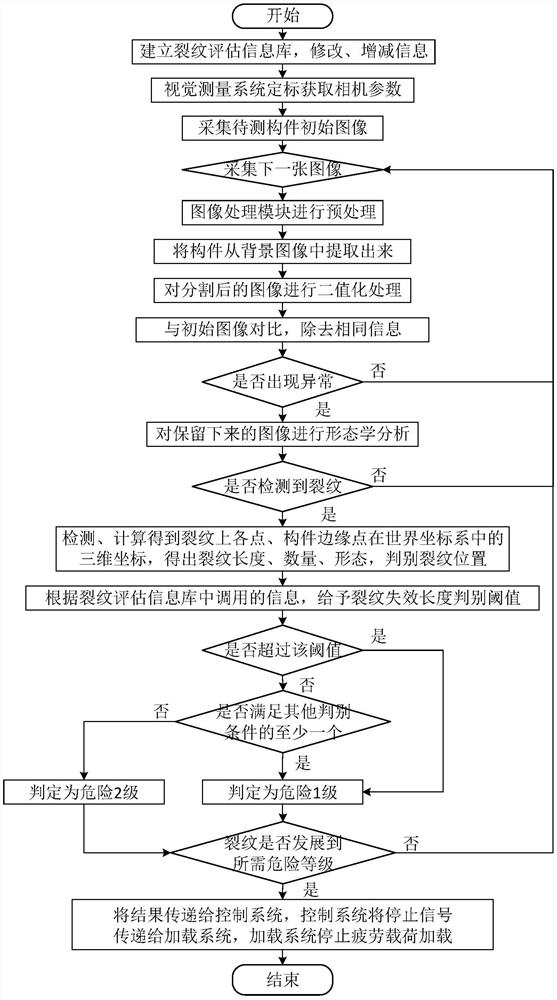

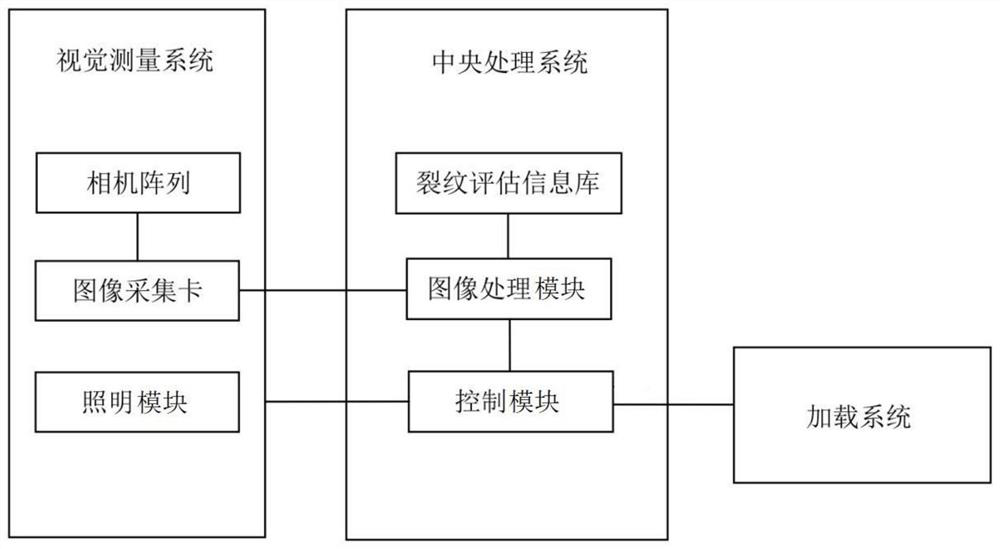

[0035] The fatigue test crack monitoring method according to the embodiment of the present invention includes the following steps:

[0036] S1. Establish a crack assessment information base, including material mechanical properties, dangerous crack patterns of specific materials, and common workpiece dangerous locations. Further, the crack assessment information base is of an interactive type, and the information in the crack assessment information base can be modified, called, increased or decreased as required.

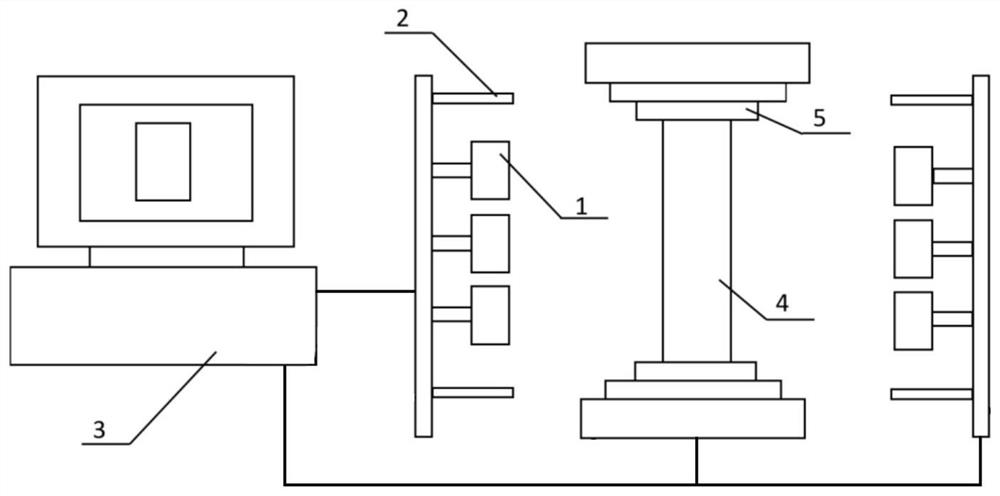

[0037] S2. For example, using a camera array, collect an initial image of the component to be tested and a monitoring image of the component to be tested in the process of bearing the fatigue load. And the camera calibration method is used to obtain the internal and external parameters of the camera for subsequent three-dimensional coordinates. After the i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com