Incineration boiler integrated system for efficiently treating high-calorific-value garbage

A high calorific value, garbage technology, applied in the direction of incinerator, combustion product treatment, combustion chamber, etc., can solve the problems of short residence time, garbage can not fall freely, garbage tumbling uneven, etc., to achieve enhanced radiation heat and convective heat transfer , Reduce the loss of incomplete combustion, the effect of large coverage area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

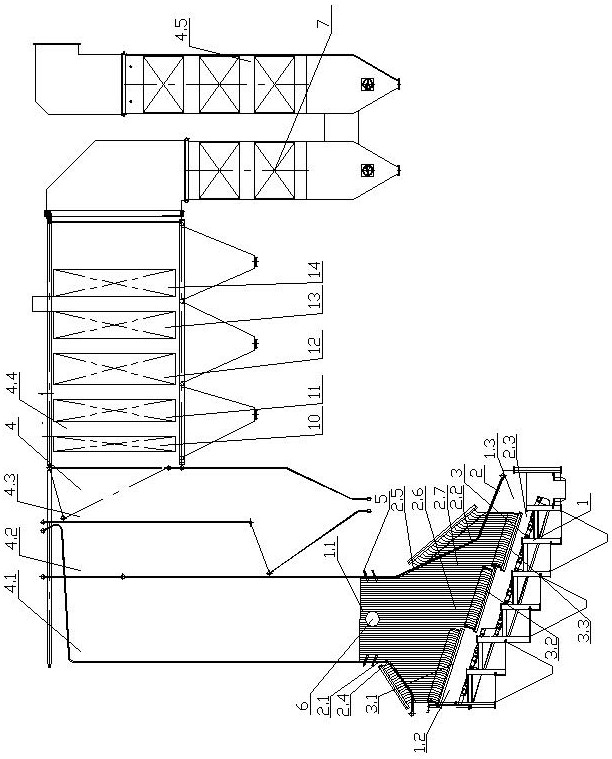

[0036] Such as Figure 1-7As shown, the present invention comprises a fire grate frame 1, and a water-cooled furnace 2 is arranged on the fire grate frame 1, and a fire grate 3 installed on the fire grate frame 1 is arranged in the water-cooled furnace 2, and the fire grate 3 includes sequentially arranged obliquely arranged Grate 3.1 in the drying section, grate 3.2 in the combustion section and 3.3 in the burnout section, the included angles between the grate 3.1 in the drying section, 3.2 in the combustion section and 3.3 in the burnout section and the horizontal line are all a, a=15 °~18°, more preferably, a=17.6°.

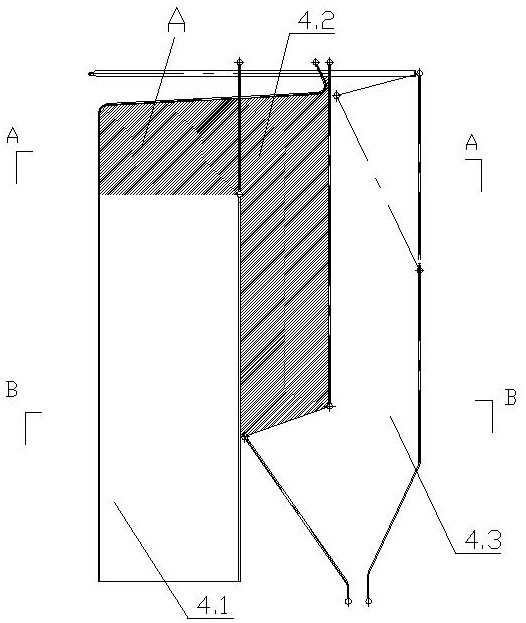

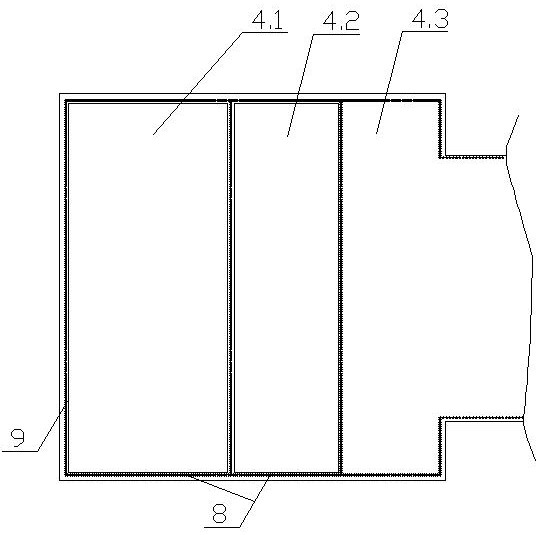

[0037] The upper end of the water-cooled furnace 2 is provided with a flue gas outlet 1.1, the front end is provided with a garbage inlet 1.2, and the rear end is provided with a slag outlet 1.3. The flue gas outlet of the water-cooled furnace 1 is connected with a flue group 4. The water-cooled furnace 2 includes a front arch 2.1, The rear arch 2.2 and the f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com