Combination installation safety special construction process for steel truss of coal conveying trestle

A construction technology and combined installation technology, which is applied in the field of special construction technology for the safety of combined installation of steel trusses of coal conveying trestle bridges, can solve the problems of long construction period, many high-altitude operations, and large area occupied by installation and operation scaffolding.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

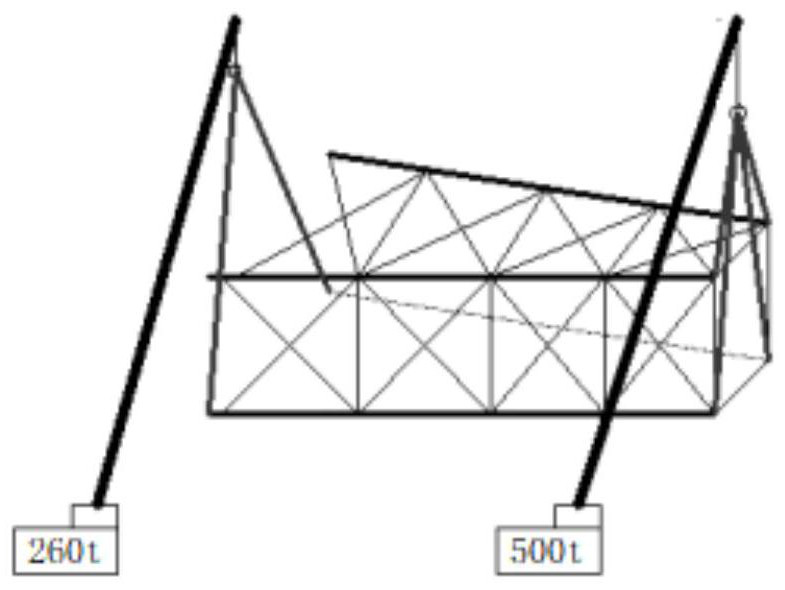

[0091] A special safety construction technology for the combined installation of steel trusses on a coal transportation trestle bridge, comprising the following steps:

[0092] Step 1. Material inspection

[0093] Check the appearance of the steel for defects such as interlayers, cracks, heavy rust, pitting, etc. The depth of corrosion, pitting, and scratches on the steel surface shall not exceed 1 / 2 of the negative thickness deviation, and check whether the steel has large bending and twisting phenomena;

[0094] Step 2. Lofting and drawing lines

[0095] (1) Standardize the erection of the construction platform, and carry out scribing and lofting on the platform according to the actual size of the components on the drawing. When scribing, sharpen the end of the stone pen to reduce the error of scribing, and mark it with white paint;

[0096] (2) Steel components such as steel trusses and connectors must be filled with large samples on site, and the materials should be cut a...

Embodiment 2

[0274] Embodiment 2 application example

[0275] Inner Mongolia Jiutai New Material Co., Ltd. annual output of 1 million tons of ethylene glycol project coal delivery island project

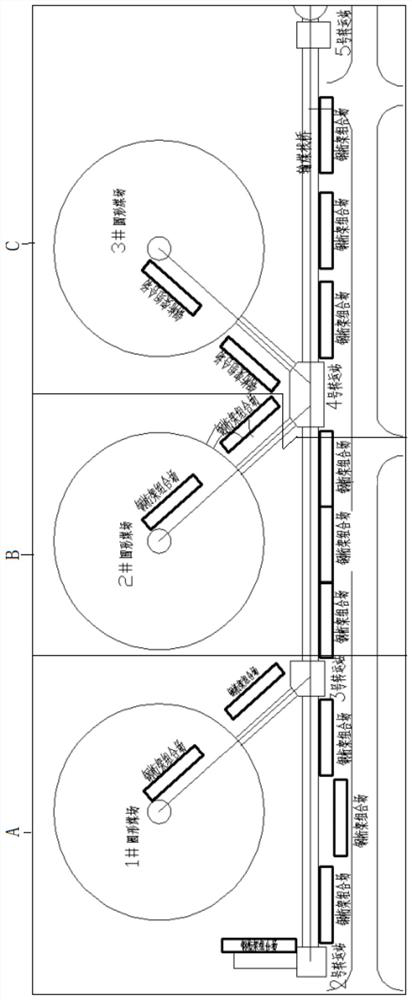

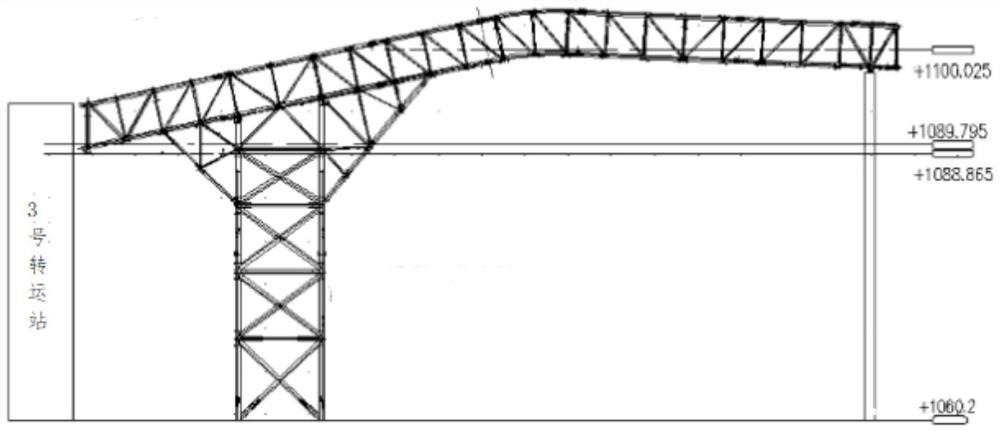

[0276] Project overview: This construction technology is applied in the special construction for the safety of the steel truss combination installation of the coal transportation trestle bridge. The construction scope of this project is between the No. 1 transfer station and the No. 5 transfer station, and between the transfer station and the stacker-reclaimer. The construction of this project will start on March 18, 2020 and will be completed on May 30, 2020. Construction The effective time is 73 days, and the field application and effect are ideal.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com