Auxiliary device for mounting glass kiln electrode brick equipment

A glass furnace and auxiliary device technology, applied in glass furnace equipment, glass manufacturing equipment, manufacturing tools, etc., can solve the problem of inaccurate size of reserved expansion joints, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

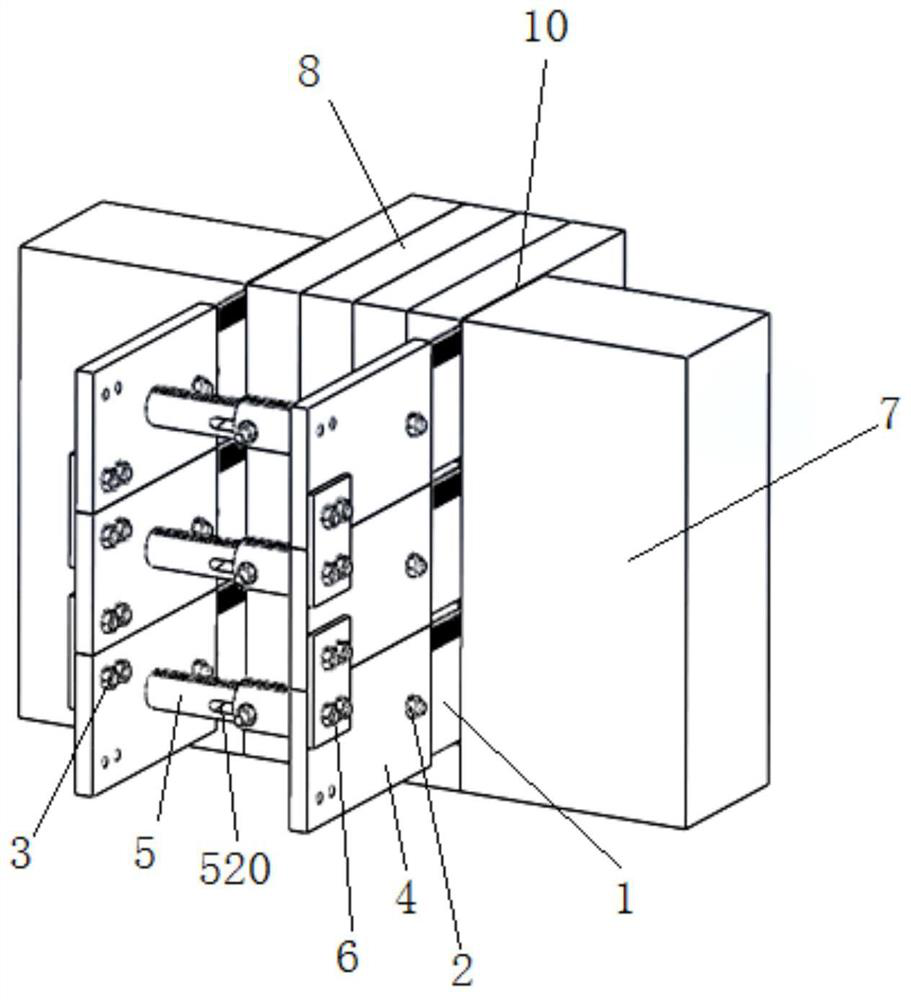

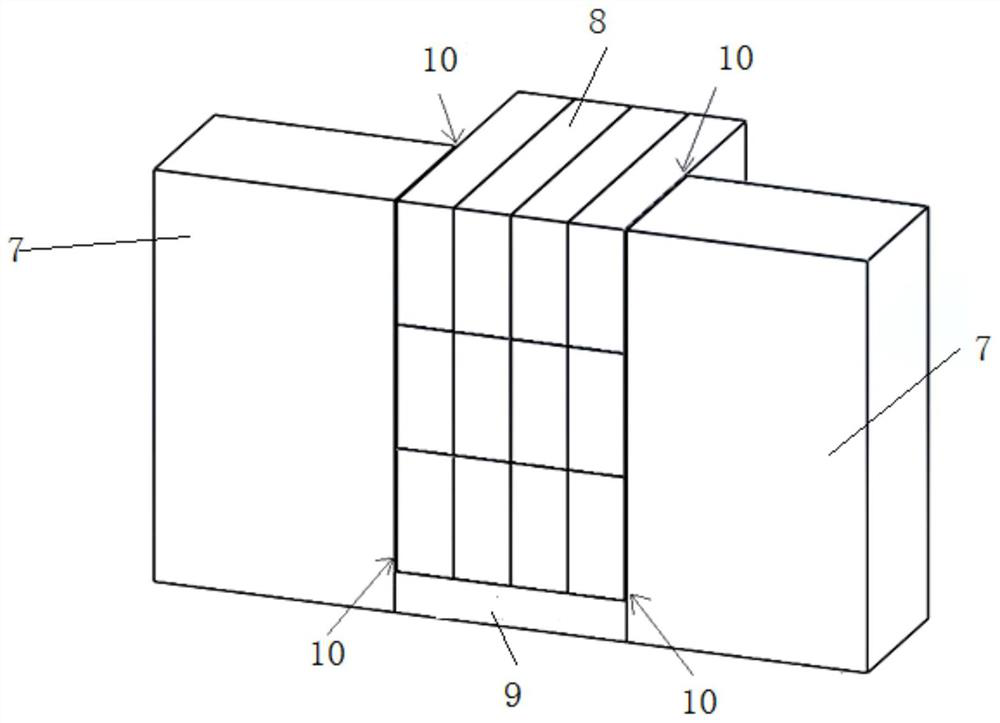

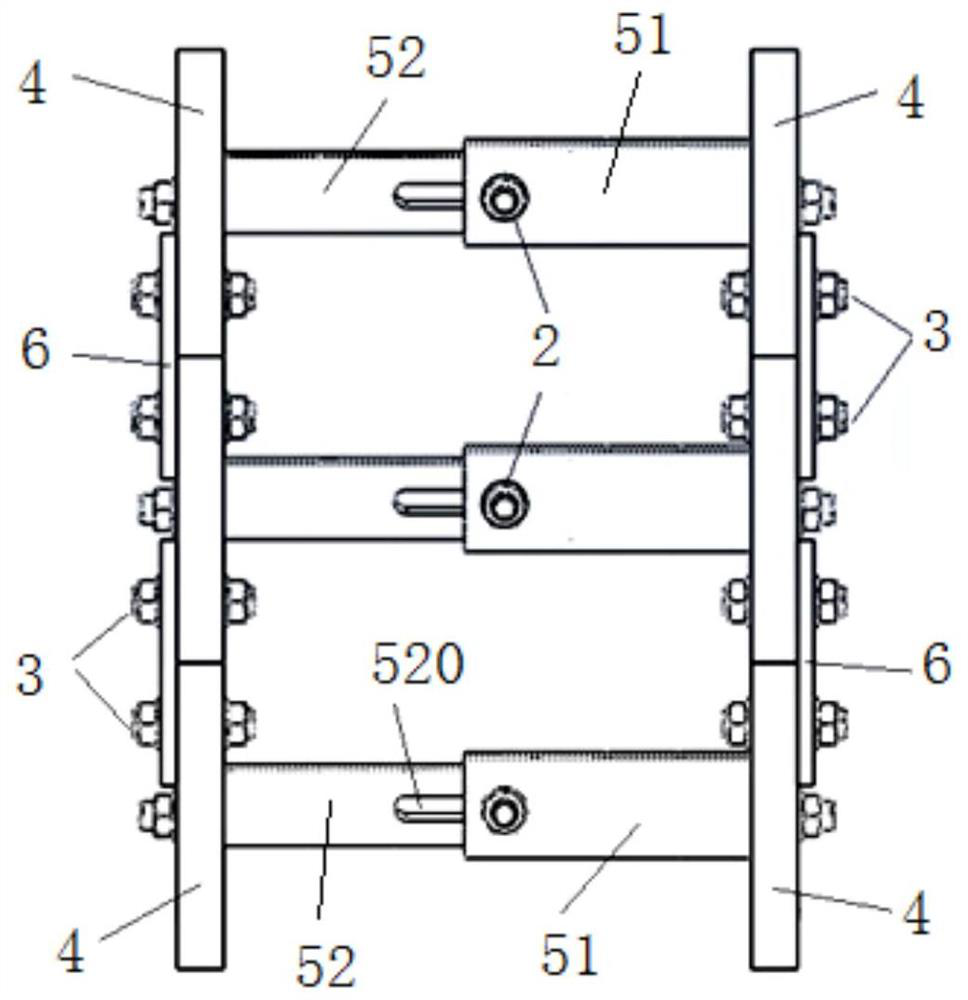

[0032] An embodiment of the present invention provides an auxiliary device for installing electrode brick equipment for a glass furnace. According to the electrode brick during installation, it is necessary to reserve a longitudinal gap between the electrode brick and the pool wall brick. When the pool wall brick is under high temperature, it has a small amount of horizontal expansion, and the expansion force can be absorbed through the longitudinal gap to ensure that the electrode brick and the pool wall brick do not squeeze each other during expansion. Therefore, it is necessary to reserve a gap when installing in a cold state. However, through continuous practice, it has been found that the size of the gap cannot fully meet the technical requirements of the process, and there are large and small influences.

[0033] Such as Figure 1~5 As shown, an auxiliary device for installing the electrode brick equipment of a glass kiln, including: an inserting plate unit and a conne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com