Synthetic fiber integrated winding device

A synthetic fiber and winding device technology, which is applied in transportation and packaging, textiles and papermaking, and conveying filamentous materials, etc. It can solve the problems of long spinning process, waste of infrastructure projects, and high factory building height, and reduce labor costs. , Reduce the cost of infrastructure, and the effect of small spinning position distance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

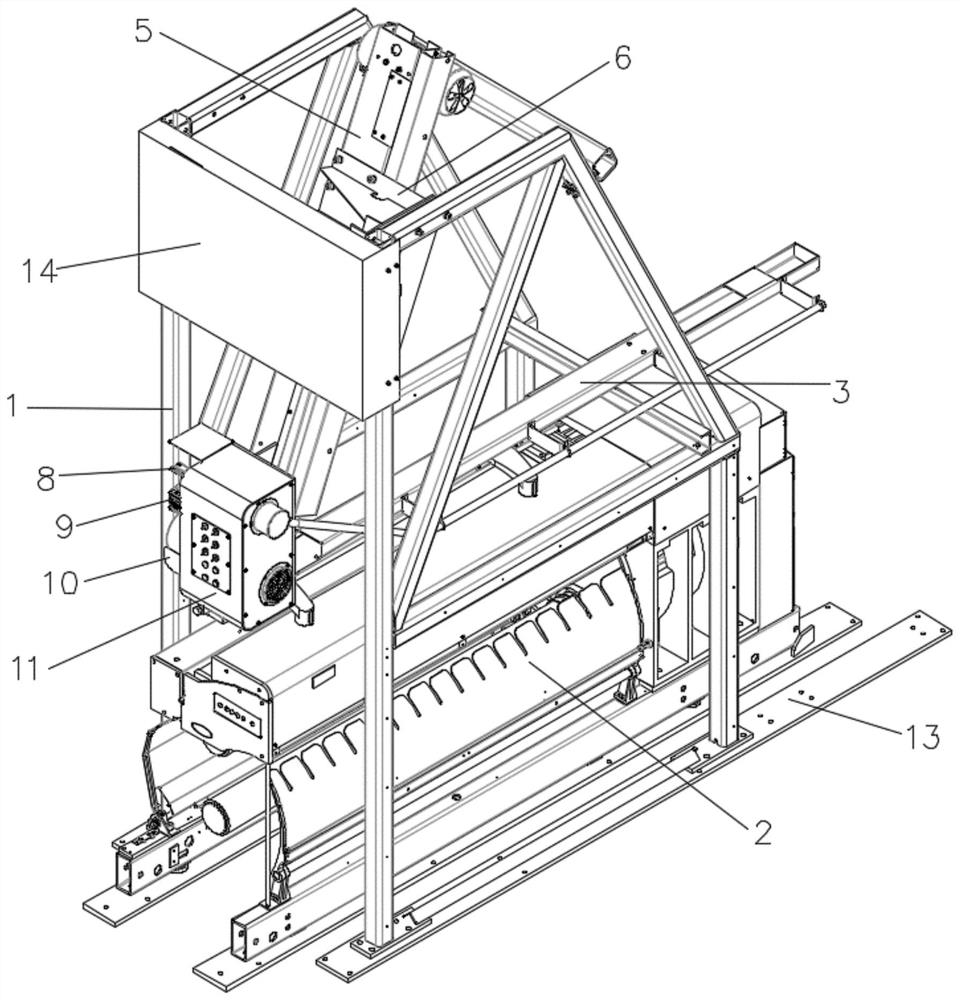

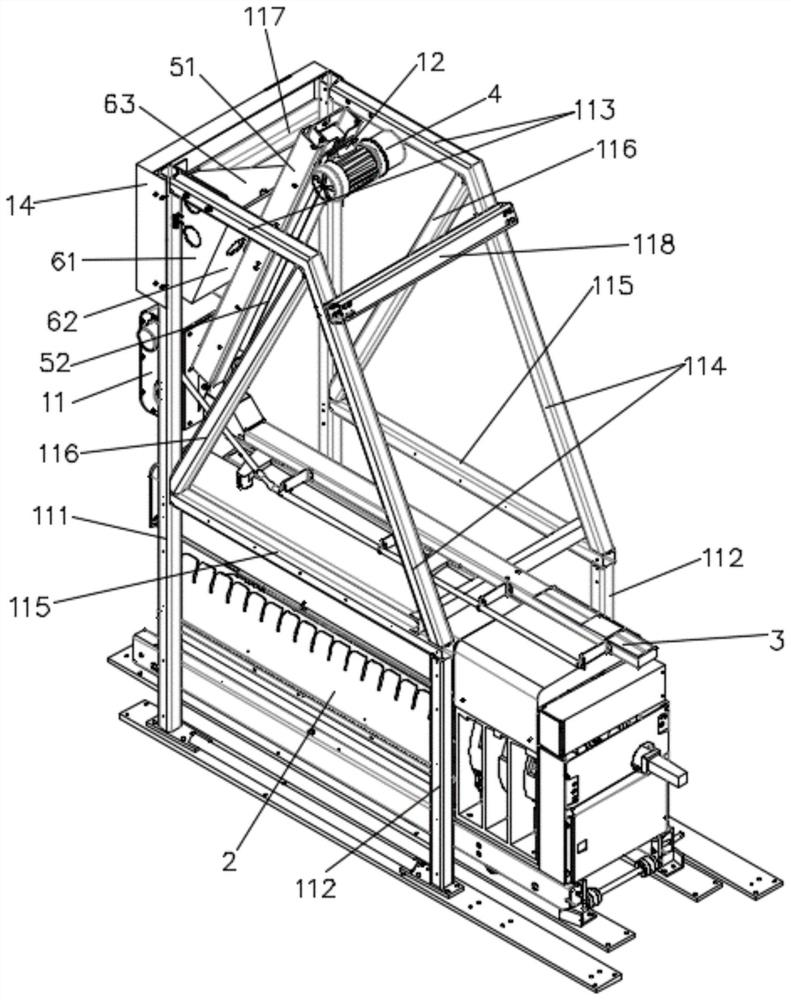

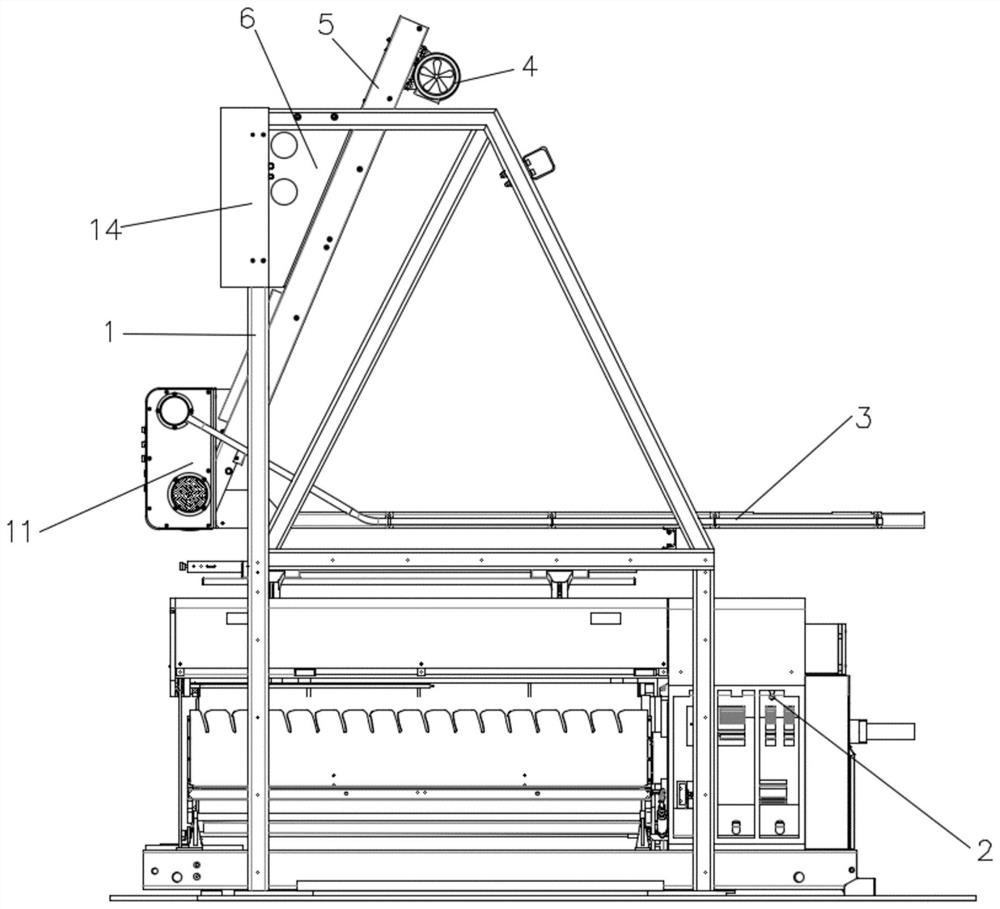

[0031] The embodiment of the present application provides a synthetic fiber integrated winding device, which solves the problem that in the prior art, because the winding device is divided into upper and lower layers by a steel platform, two operators are required to perform the spinning operation, and the spinning process The time is long, there are many waste silks, and operation errors are easy to occur, and this kind of device occupies a large area, and the height of the required factory building is high, which is a technical problem of great waste for infrastructure projects.

[0032] The technical solution in the embodiment of the present application is to solve the above-mentioned technical problems, and the general idea is as follows:

[0033] By combining the operations of drawing and winding units from two levels to one level, the device is greatly reduced, the occupied area is reduced, the production capacity is increased, the cost of engineering infrastructure is re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com