Electric vacuum pump driving sleeve assembling device

An electric vacuum pump and suit technology, which is applied in workpiece clamping devices, metal processing, metal processing equipment, etc., can solve the problems of easily damaged motors and large pressing force, and achieve the effect of avoiding motor damage and novel structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

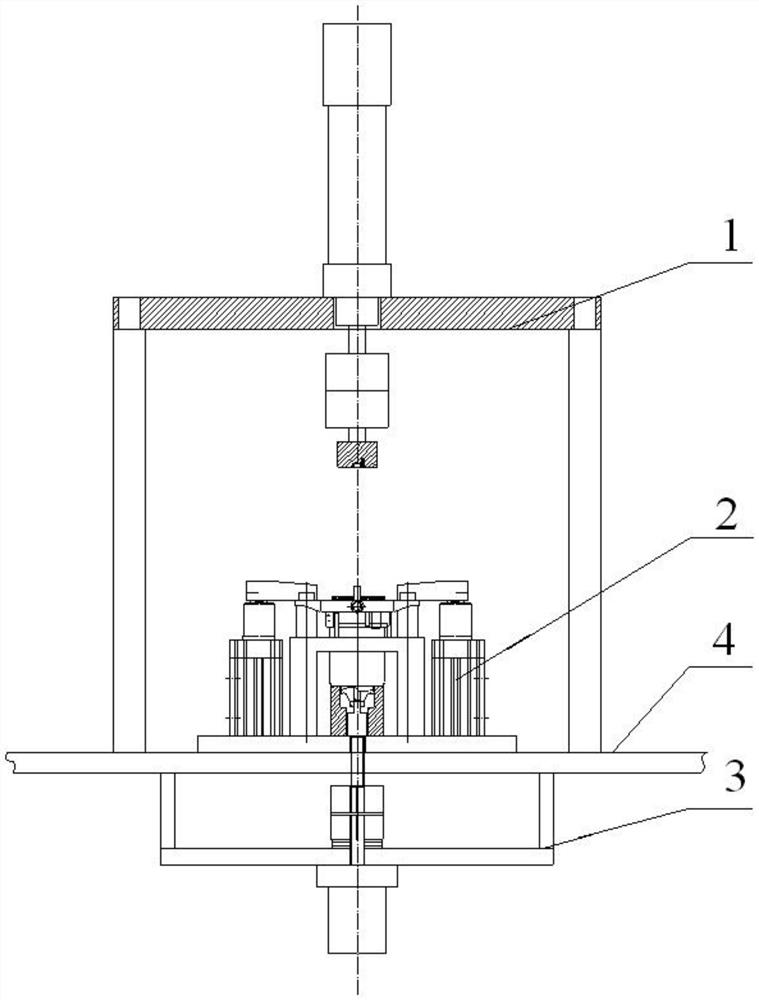

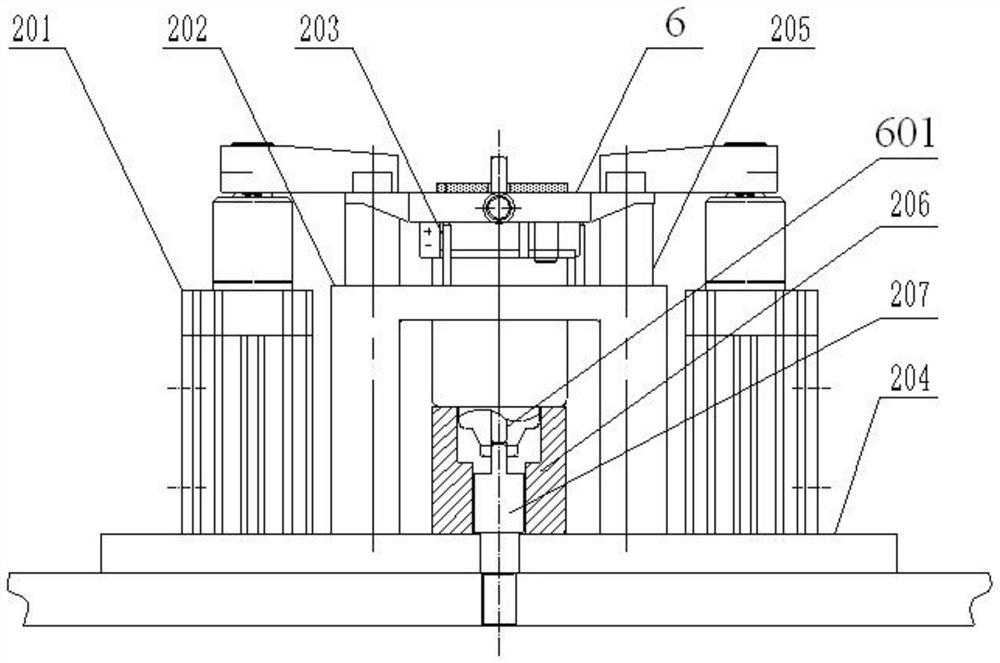

[0017] The fixed frame 104 of the electric press-fit mechanism 1 is fixedly connected to the top of the workbench 4, the workpiece clamping mechanism 2 is located below the electric press-fit mechanism 1 and fixedly connected to the top of the workbench 4, and the support frame 302 of the gap locking mechanism 3 is connected to the workbench 4. The bottom of the table 4 is fixedly connected, the upper end of the driven screw 304 of the gap locking mechanism 3 is threaded through the worktable 4, and the top end of the driven screw 304 passes through the relief hole and the top of the fixed plate 204 of the workpiece clamping mechanism. The bottom surfaces of the shaft blocks 207 are in contact.

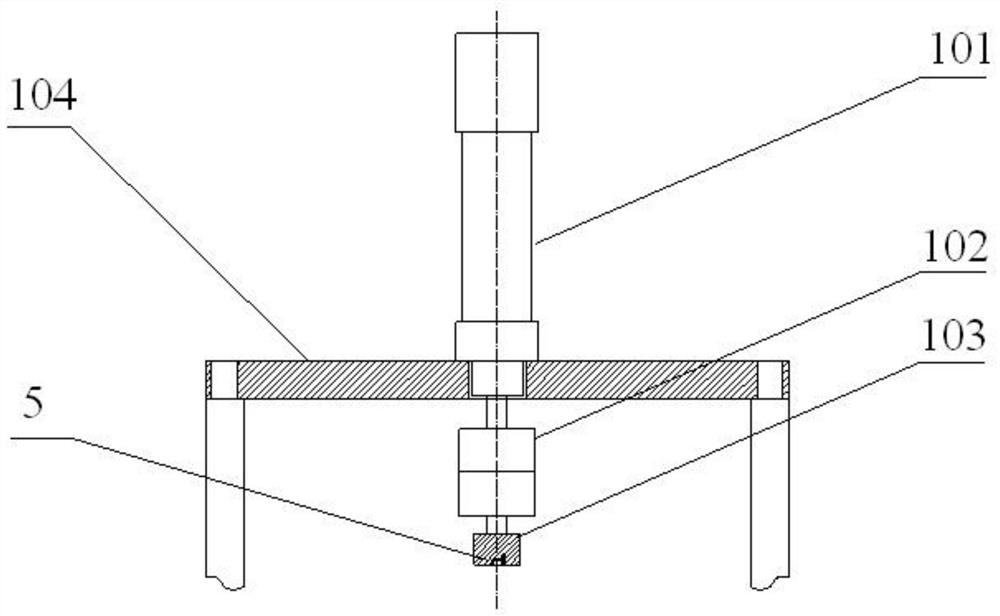

[0018] The structure of the electric press-fitting mechanism 1 of the present invention is that the servo electric cylinder 101 is fixedly connected with the fixed frame 104, the pressure sensor 102 is connected in series with the press-fit end of the servo electric cylinder 101, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com