Line hooking and knotting equipment for badminton production and manufacturing

A badminton and hook line technology, applied to rackets, balls, sports accessories, etc., can solve the problems of large consumption, unstable processing quality, restrictions on the automatic transformation process and production efficiency of badminton production lines, and achieve high operating fluency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

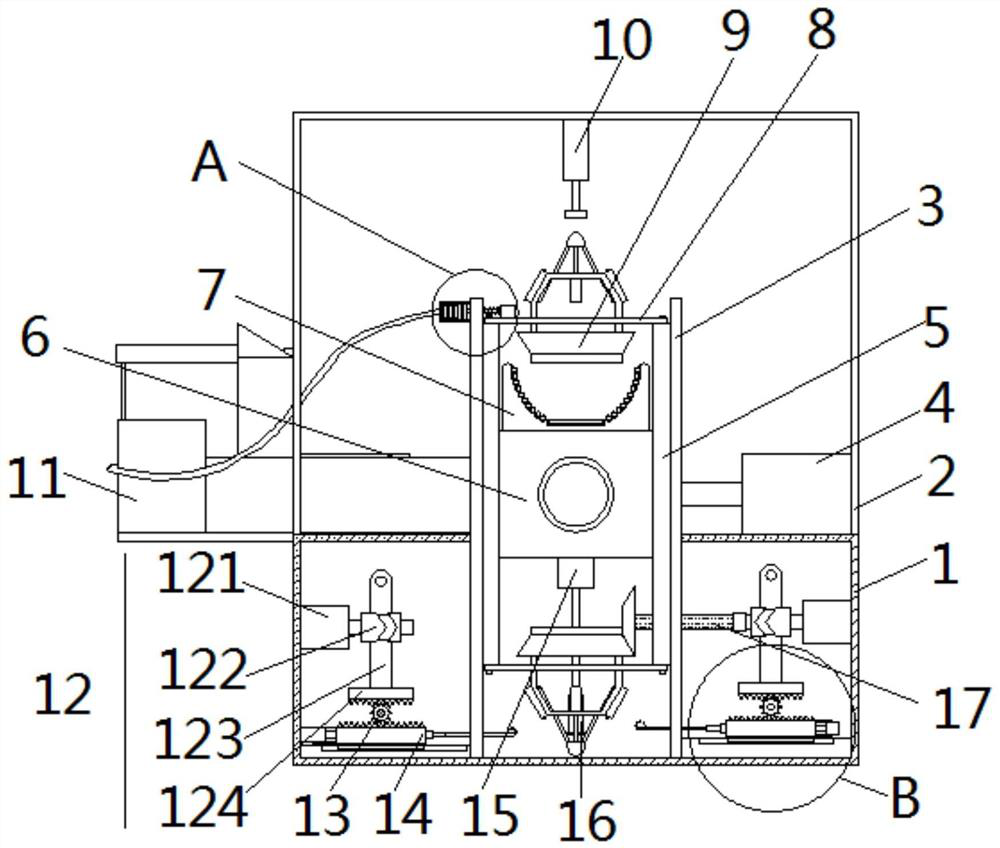

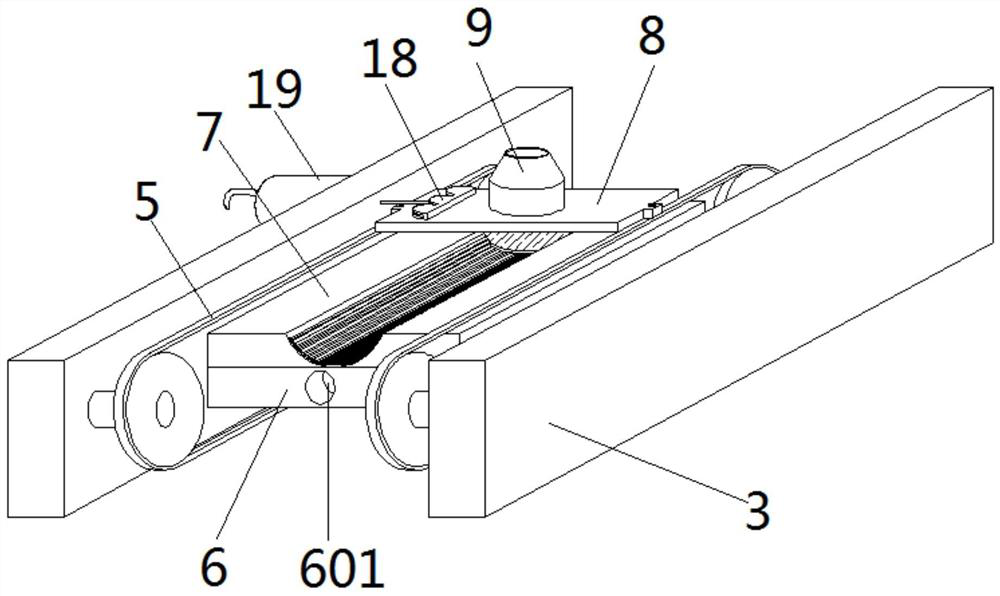

[0032] as attached figure 1 to attach Figure 10 Shown: a hook thread knotting device for badminton production, including a box body 1, a molded plate 2, an output mechanism 7, a loading mechanism 9, a feeding mechanism 11, a telescopic drive mechanism 12, a hook thread mechanism 14, a wire release mechanism Mechanism 16, the top of the box body 1 is fixedly connected with a molded plate 2, the center of the top of the box body 1 is in the shape of a gap, the inner bottom of the box body 1 is located on the left and right sides of the gap and is vertically fixedly connected with side plates 3, and the top of the side plate 3 Extending to the outside of the box body 1, the front and rear ends of the adjacent side of the side plate 3 are horizontally and vertically rotated and connected with sprockets, and the upper end of the side plate 3 is sleeved with a conveyor chain 5 between the front and rear sprockets, and the conveyor chain 5 is away from the sprockets by one A suppor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com