Compressed tea production equipment

A kind of production equipment and technology of compressed tea, which is applied in the field of compressed tea production equipment, can solve the problems of poor flavor, obvious bitterness and astringency of tea cakes, and uneven distribution, so as to achieve uniform distribution of internal voids, improve the quality of compressed tea, and even gap effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] Specific embodiments of the present invention will be described below with reference to the accompanying drawings.

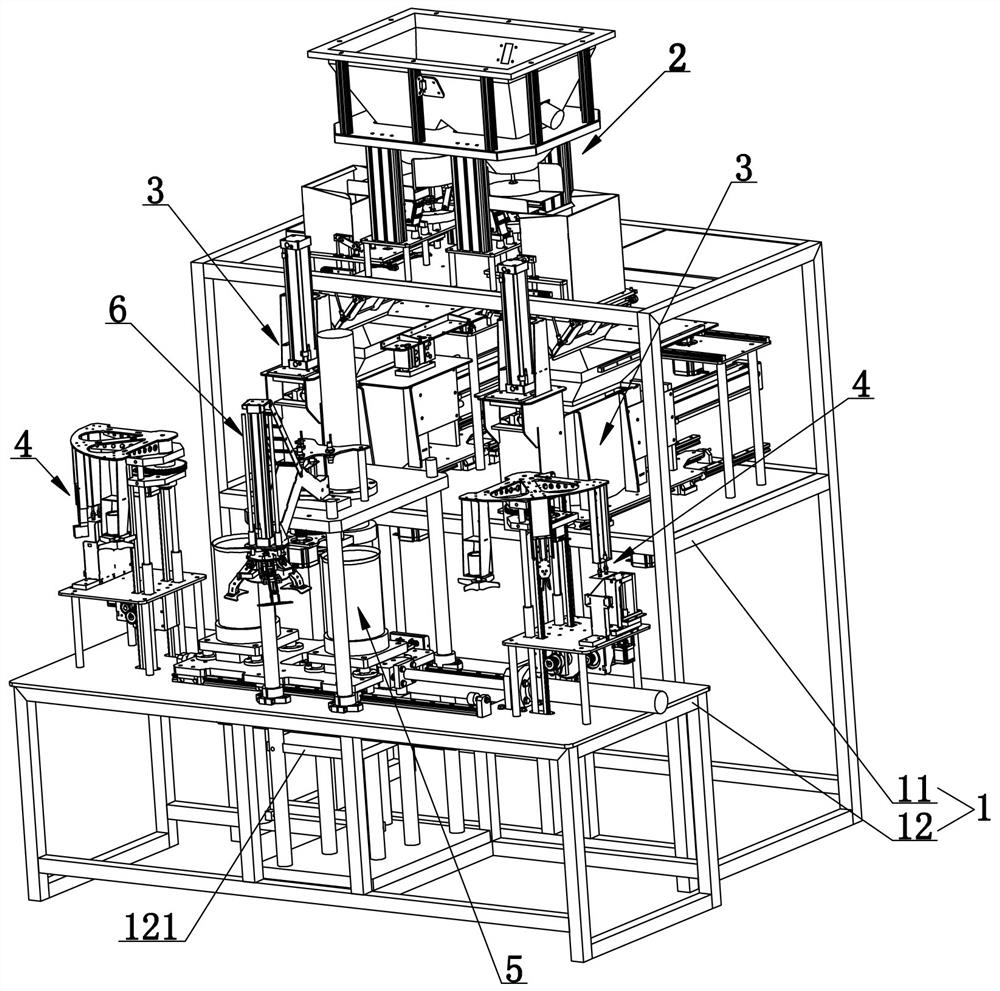

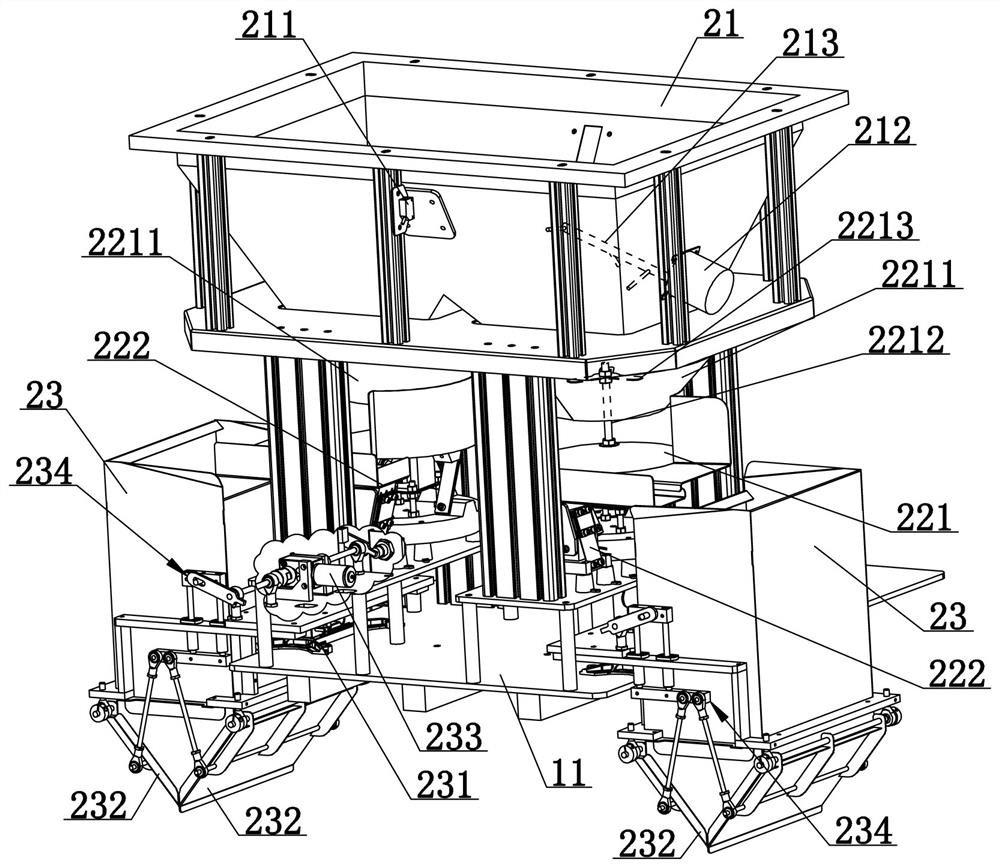

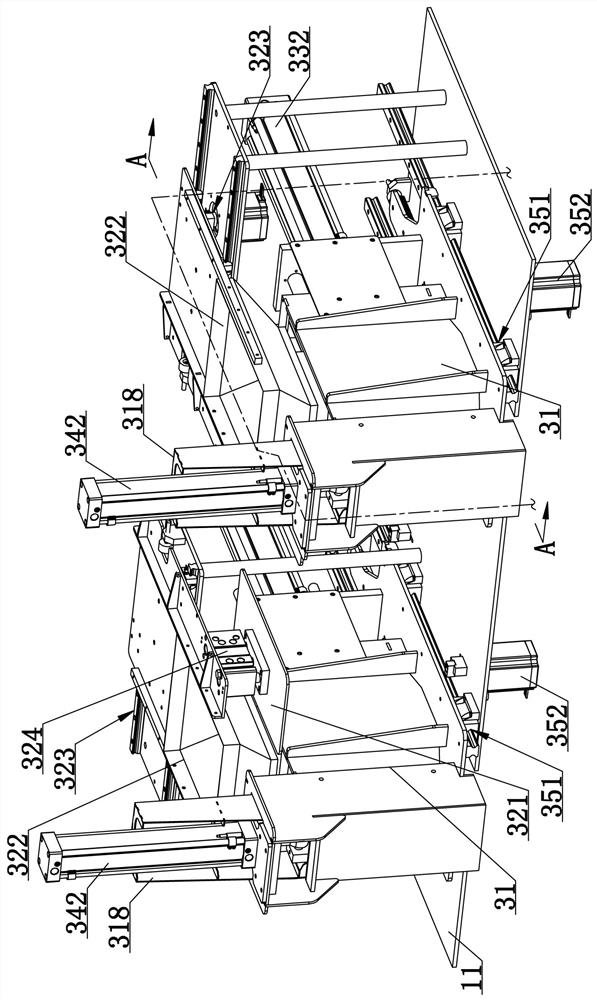

[0034] refer to figure 1 , a pressed tea production equipment, comprising a frame 1, a feeding device 2, a tea steaming device 3, an auxiliary device 4, a tea pressing device 5 and a discharging device 6, wherein:

[0035] The frame 1 is used to carry the feeding device 2, the tea steaming device 3, the auxiliary device 4, the tea pressing device 5, the discharging device 6, and the connection between the above-mentioned devices, material transfer and other matching components. The setting of the frame 1 is specific. According to the actual pressed tea production process, it needs to be built in accordance with the specific requirements of the above-mentioned devices; specifically, the above-mentioned frame 1 is composed of a first frame body 11 and a second frame body 12, and the first frame body 11 and the second frame body 12 are opposite to each other...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com