Vacuum-coating system and method for coating a strip-type material

A coating and strip-shaped technology, applied in vacuum evaporation plating, metal material coating process, coating, etc., can solve problems such as wear, vacuum damage, and damage to the coating process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

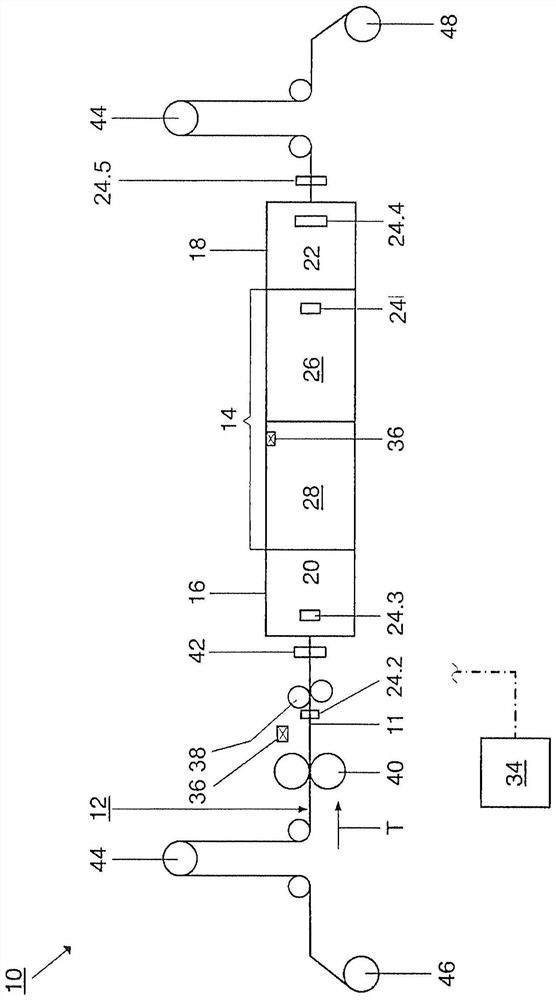

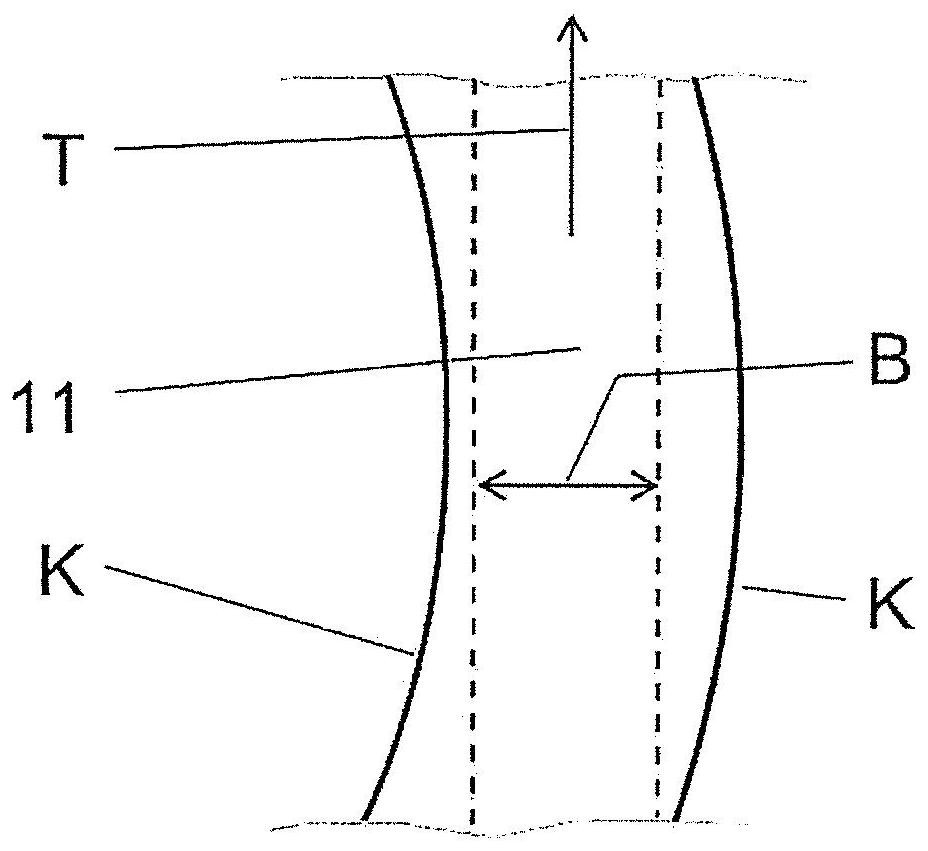

[0025] The invention provides a vacuum coating device 10 with which a strip-shaped material 11 can be provided with a coating on at least one side thereof, preferably on both sides (upper side and lower side). Accordingly, a method can also be carried out with such a vacuum coating system 10 for coating, in particular, a strip-shaped material 11 . Identical features are provided with the same reference numerals in both figures. It should also be pointed out here that the figures are only simplified and in particular not shown to scale.

[0026] The strip-shaped material 11 can consist of metal, in particular steel or high-grade steel or corresponding alloys thereof. Furthermore, it should be pointed out that the strip-shaped material 11 coated with the vacuum coating device 10 can be a hot-rolled strip (Warmband) or a cold-rolled strip (Kaltband).

[0027] Next, the vacuum cladding equipment 10, its various components and its working principle are explained in detail:

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com