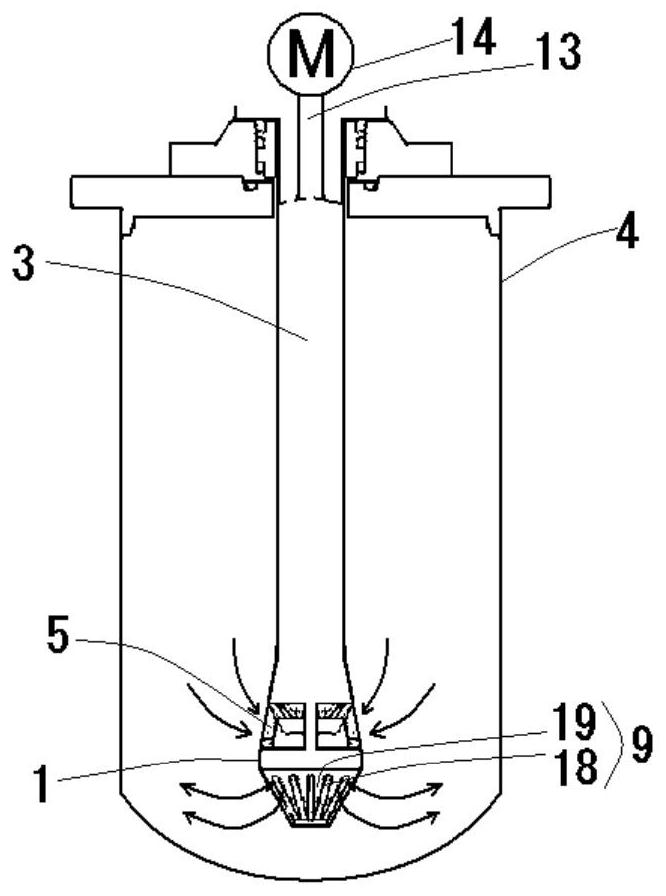

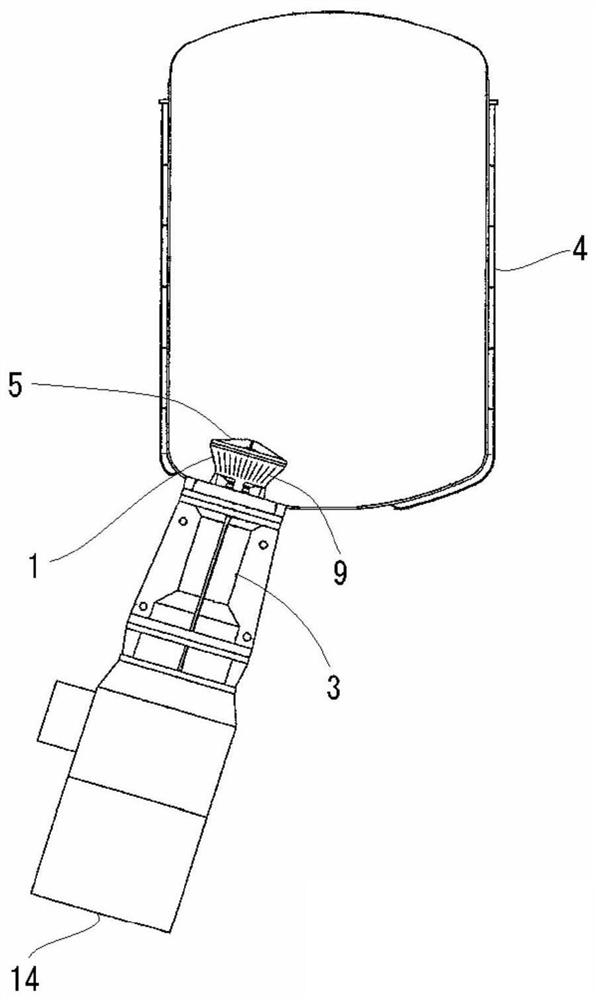

Stirrer

A mixer and screen technology, which is applied to mixers with rotating stirring devices, mixers, fluid mixers, etc., can solve the problems of speeding up the rotation speed of the rotor, sucking the fluid to be processed, etc., and achieve the promotion of micro-particles, The effect of uniform particle diameter and narrow distribution of particle diameter

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0122] Hereinafter, examples and comparative examples are given to describe the present invention more specifically. However, the present invention is not limited to the Examples described below.

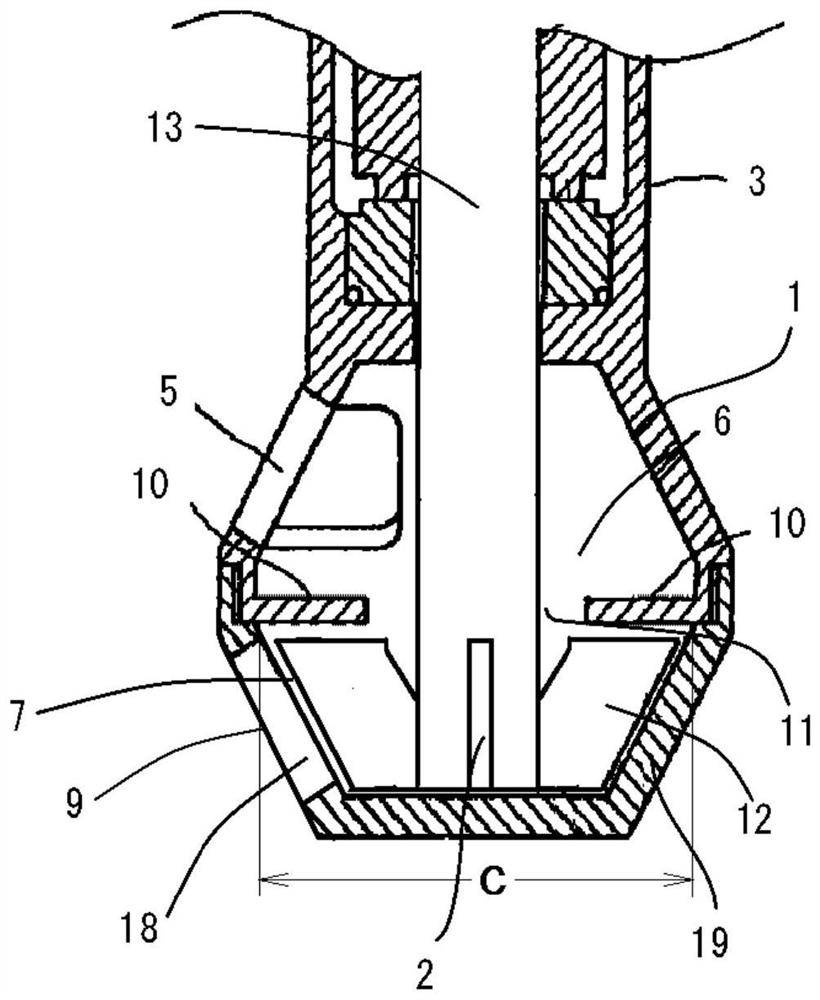

[0123] exist Figure 10 (A) to (C) show the shape of the cross section of the slit 18 used in the embodiment, in Figure 10 (D) shows the cross-sectional shape of the slit 18 used in the comparative example. The slit used in the embodiment is set so that the circumferential width (So) of the outflow opening 29 is smaller than the circumferential width (Si) of the inflow opening 28, and the slit used in the comparative example is the circumferential width (So) of the inflow opening 28. A slit whose upward width (Si) is the same as the circumferential width (So) of the outflow opening 29 (Si=So).

[0124] In more detail, the slits used in the examples, in Figure 10 In (A), there is a rounded corner (RO. Figure 10 In (B), the entire near-side end surface 22 is inclined forward i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| refractive index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com