Device and method for carrying out underwater explosion test on land

An underwater explosion, land-based technology, used in measurement devices, impact testing, machine/structural component testing, etc., can solve problems such as poor simulation accuracy, inability to accurately and accurately control boundary conditions, and high consumption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

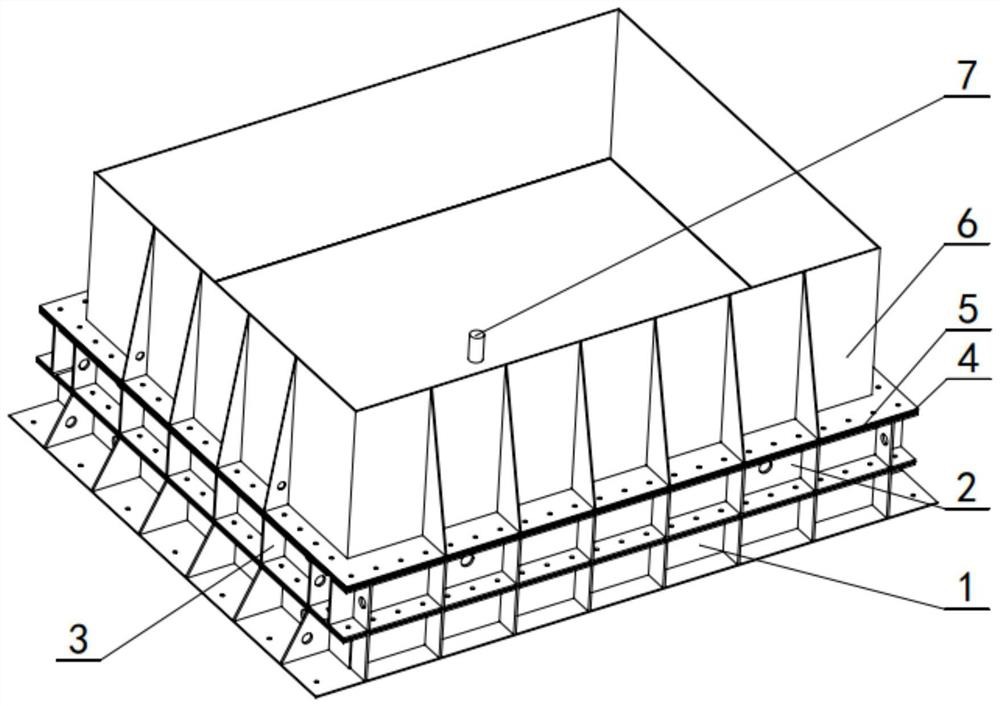

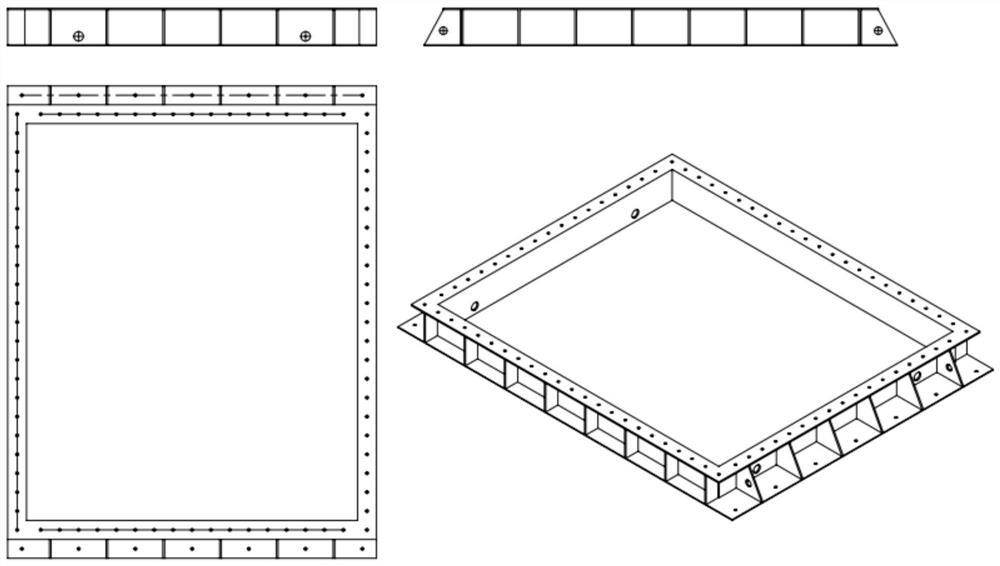

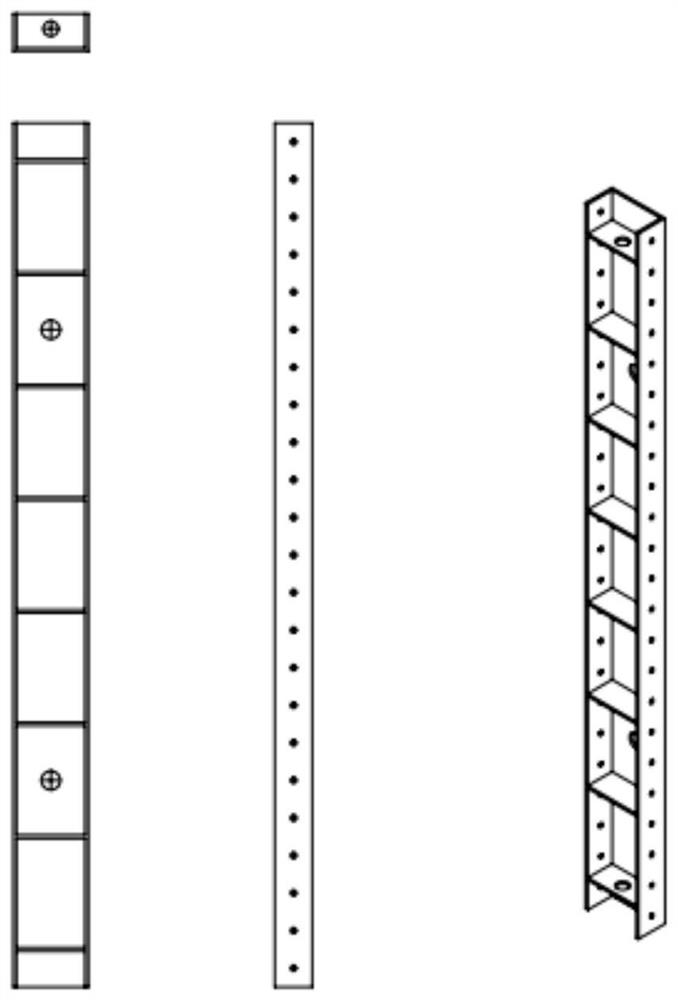

[0019] The present invention will be further described below in conjunction with the accompanying drawings.

[0020] The invention specifically relates to a device and method for conducting an underwater explosion test on land, which consists of explosives, an external water tank, a target test piece, long and short drawer tooling and bottom fixed tooling. The specific operation is to fix the base fixing tool on the ground, place the target test piece at the corresponding position, install the long and short drawer tooling and fix them with bolts, add a gasket to the upper end of the test sample, install the external water tank tooling on the top, and add bolts Secure and act as a watertight seal, placing explosives at the target location. This new test method has low cost and strong test operability, especially the control of boundary conditions is clearer, and water of different depths can be added according to different target environmental conditions, and multiple groups o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com