Annular underground garage and construction method thereof

A technology of underground garage and construction method, which is applied to buildings for parking cars, excavation, construction, etc., which can solve the problems of long period and high construction cost, and achieve the effects of reducing costs, speeding up construction progress, and improving excavation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] In order to further elaborate the technical means and effects adopted by the present invention to achieve the purpose of the invention, the specific implementation, features and effects of the ring-shaped underground garage proposed according to the present invention and its construction method are described in detail below.

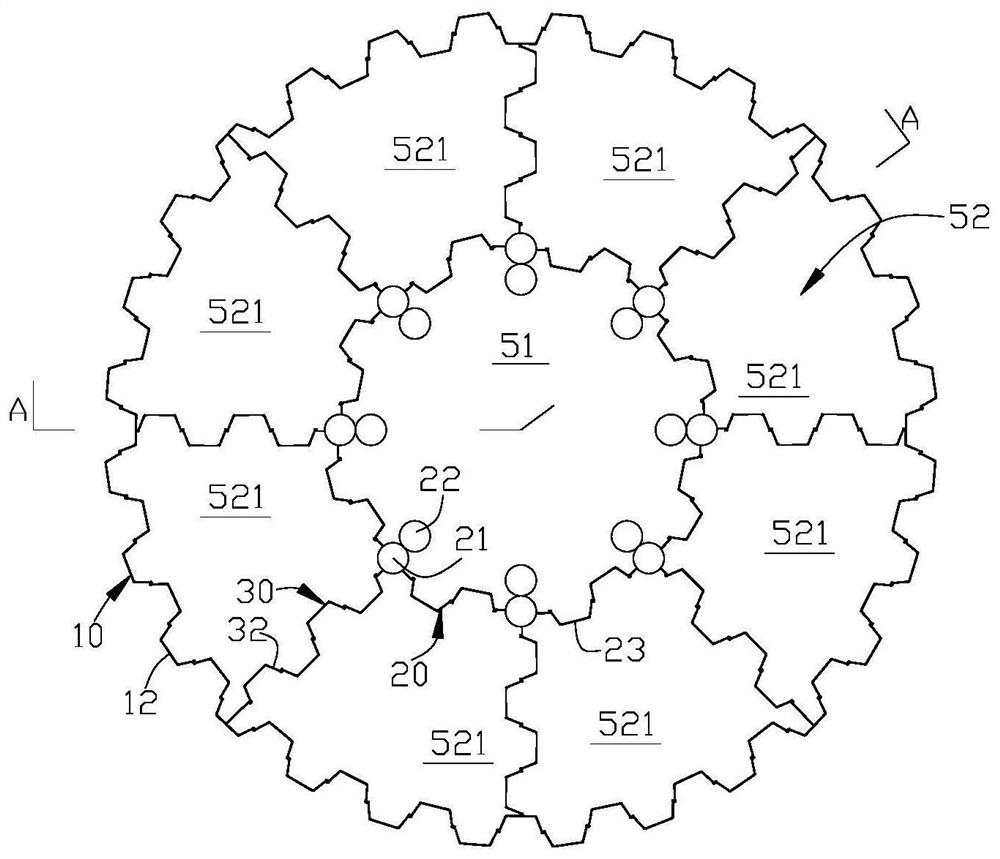

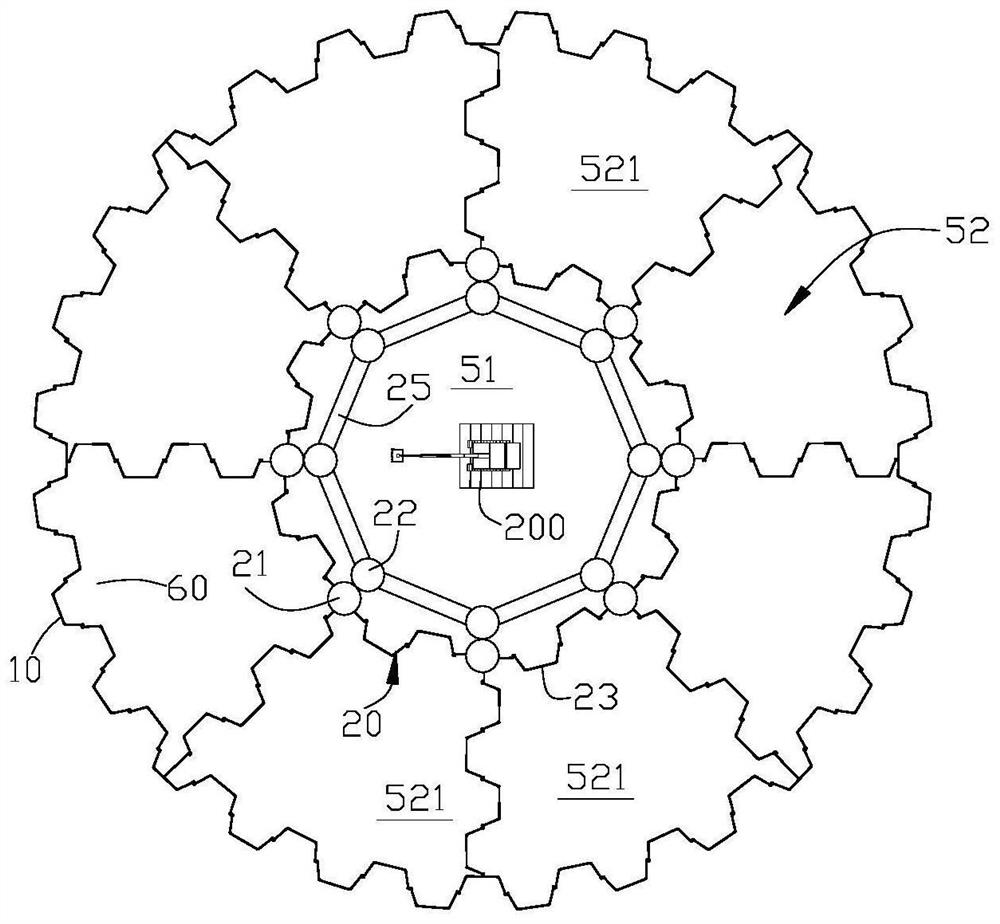

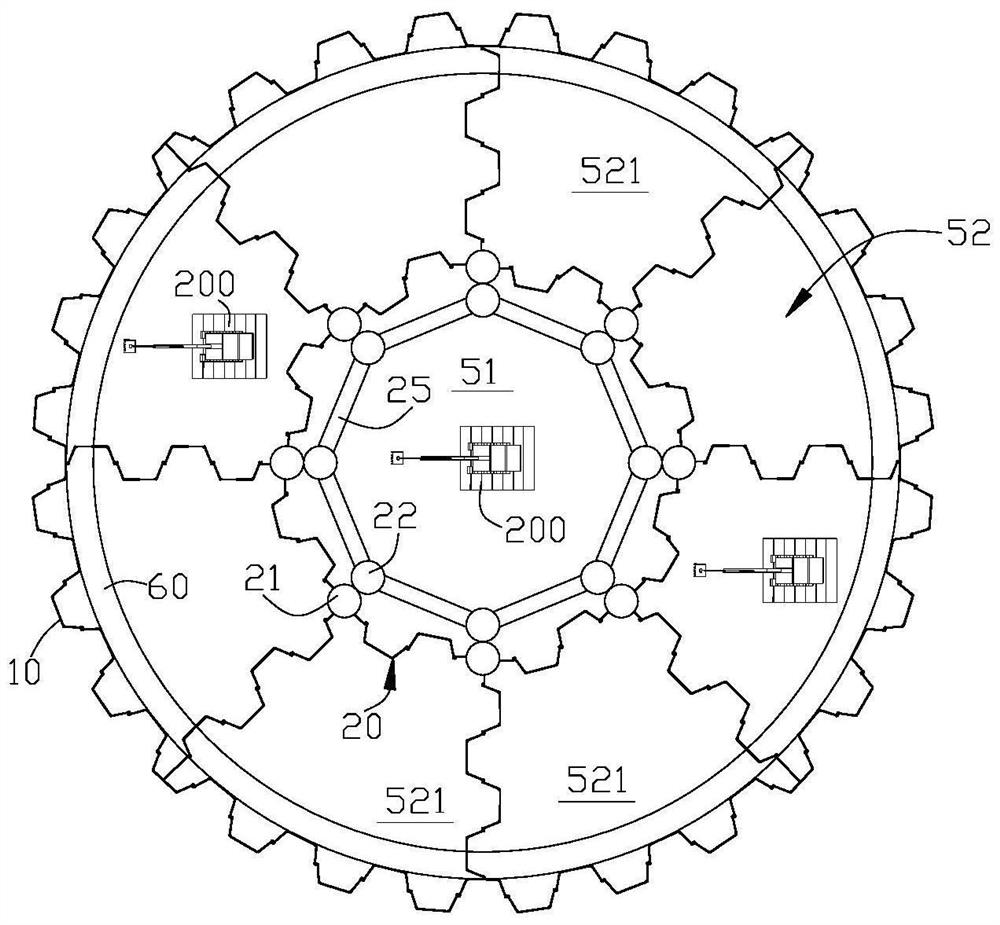

[0046] The invention discloses an annular underground garage, such as Figure 9 and Figure 10 As shown, it includes: steel sheet pile outer wall 10, which is ring-shaped; lifting channel 51, which is arranged in the steel sheet pile outer wall 10, and the lifting direction of the lifting channel 51 is the same as the height direction of the steel sheet pile outer wall 10, which is used for vehicles. The transfer between the parking floor 300 of the circular underground garage and the vehicle entrance and exit 125; the parking floor 300 is provided with multiple layers, and each parking floor 300 is arranged between the steel sheet pile outer wall...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com