Rubber protection device for hoisting cold-rolled steel coil

A rubber protection, cold-rolled steel technology, used in safety devices, transportation and packaging, load hanging components, etc., can solve the problems of inability to clamp arms and clamp feet protection, reduce labor intensity, and facilitate assembly and positioning. Ease of installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

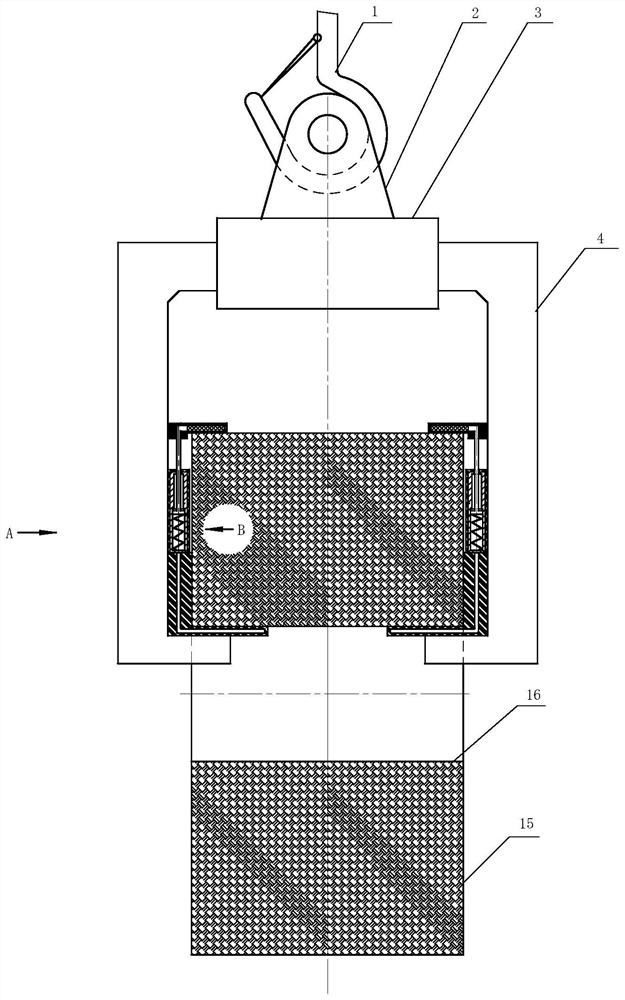

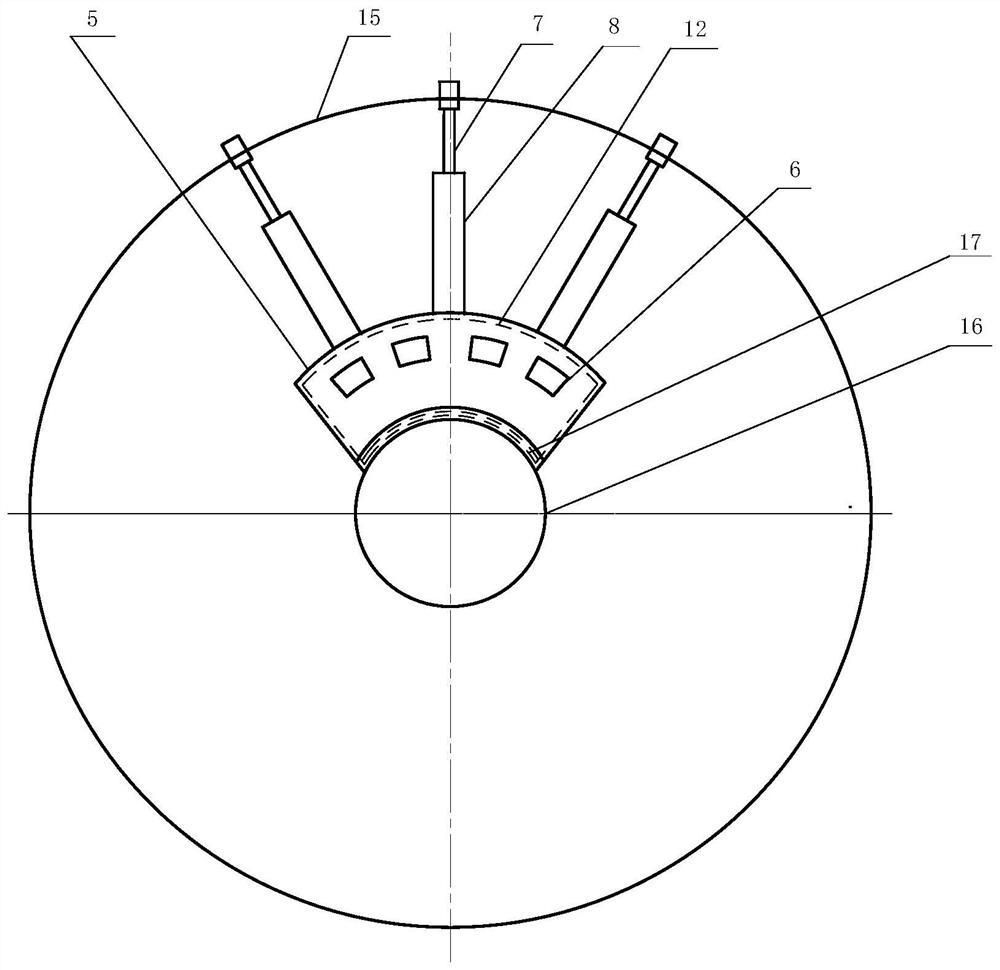

[0026] Such as figure 1 and 2 As shown, the cold-rolled steel coil lifting includes: a hook 1, a support 2, a clamp opening and closing mechanism 3 and a clamp arm 4. The rubber protective device used for hoisting cold-rolled steel coils in the present invention is installed on both symmetrical sides of the hoisted steel coil 15 respectively, and the two clamp arms 4 for hoisting the cold-rolled steel coils respectively extend into the holes 16 of the hoisted steel coil Among them, the two clamp arms 4 are respectively in direct contact with the rubber guard.

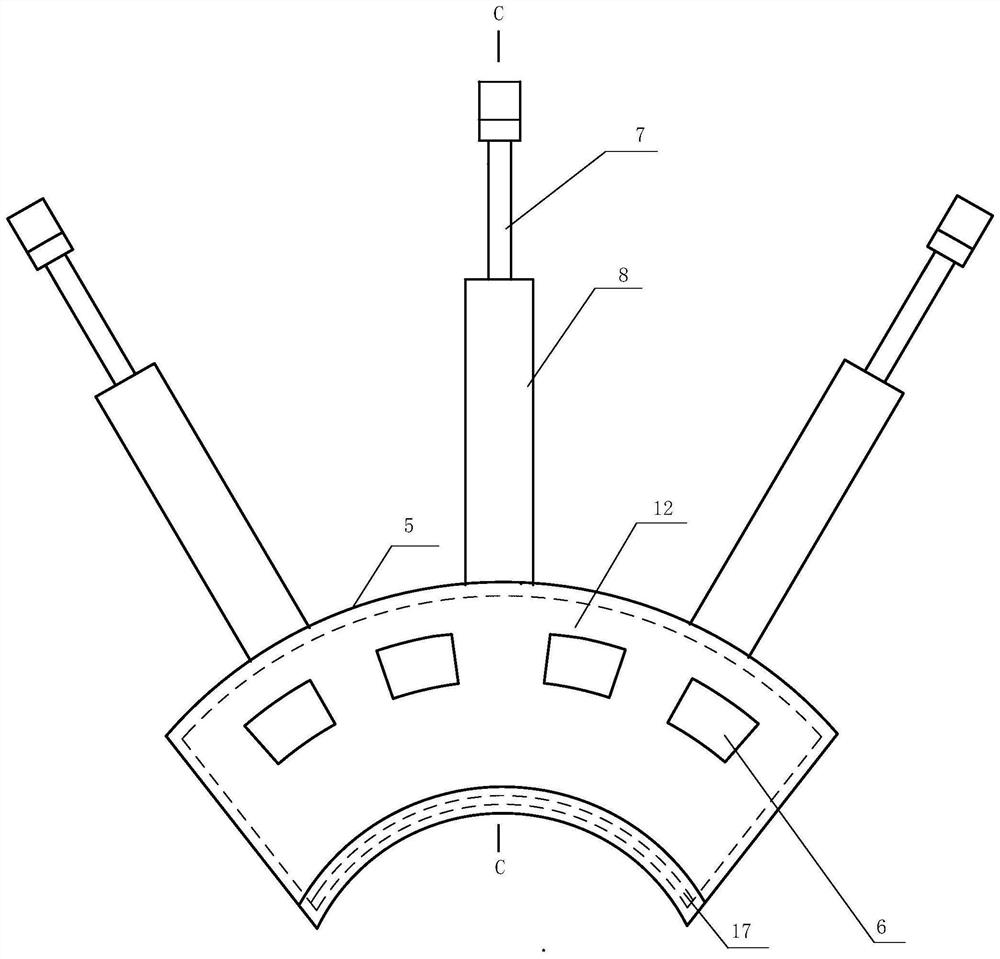

[0027] Such as Figure 3 to Figure 5As shown, the rubber protective device includes: steel plate protective layer 5, pull rod 7, steel cylinder protective cover 8, magnet positioning frame 9, spring 10, steel cylinder 11, vertical steel plate 12, suction claw protection layer 13, magnet suction claw 14 and round Arc-shaped load-bearing plate 17, the lower end of the vertical steel plate 12 is welded on one end of the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Shore hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com