Rope-driven large-motion-range flexible bionic ball socket joint

A rope-driven, ball-and-socket joint technology, applied in the field of robotics, can solve the problems of insufficient compact structure and small range of motion, and achieve the effects of convenient transportation and carrying, reducing the weight of the arm, and reducing the moment of inertia.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

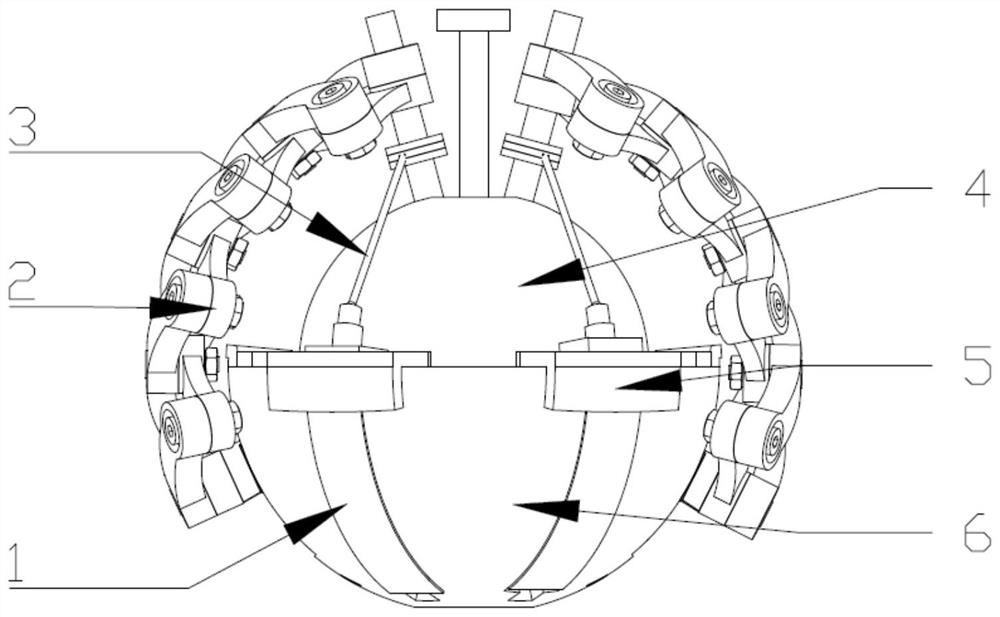

[0018] exist figure 1 Among them, a deployable mechanism 1, two spherical scissor mechanisms 2, a rope 3, a ball head 4, a chute cover 5 and a ball socket 6 together constitute the entire ball and socket joint. One end of the rope 3 is connected to the offset driving rod on the ball head 3, passes through the expandable mechanism 1, and protrudes from the bottom of the driving chute 62, and the other end of the rope 3 is connected to the driver, and the ball head 4 is driven in the ball socket 6 by controlling four ropes. inner movement.

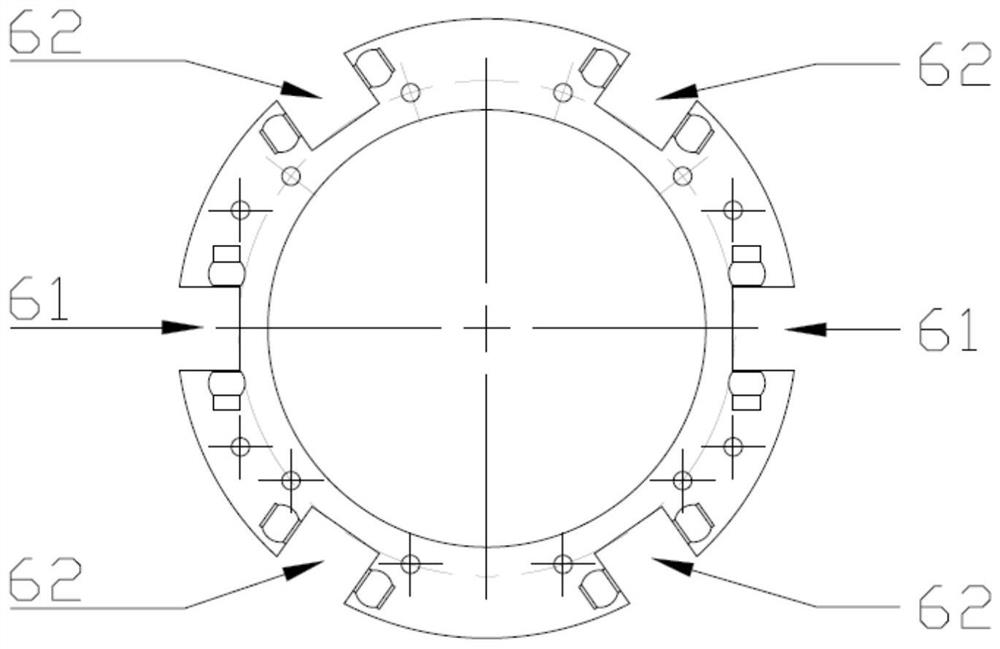

[0019] figure 2 It is a schematic diagram of the ball socket. There are 6 slide rails on the ball socket, 2 flexible slide grooves 61 connected to the spherical scissor mechanism, and 4 drive slide grooves 62 connected to the expandable mechanism.

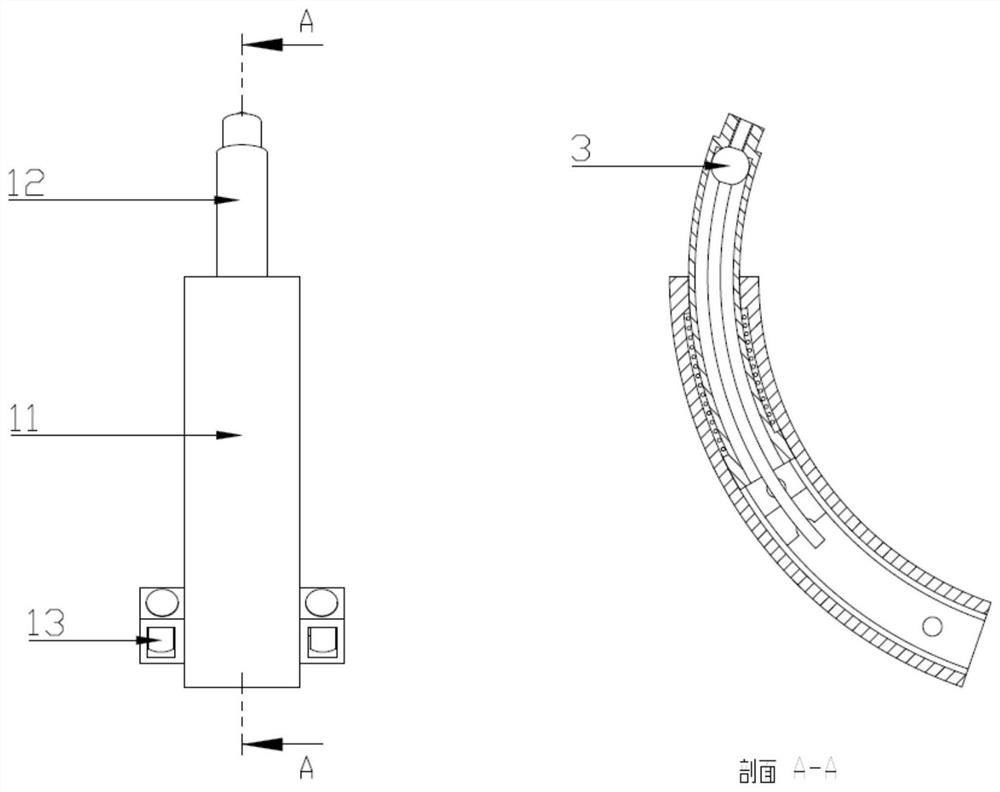

[0020] image 3 It is a schematic diagram of the deployable mechanism, two pulleys 13 are installed on both sides of the first-stage unfolding slider 11 through cylindrical pins, and the seco...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com