Mutual-insertion type semi-packaging type hydraulic turnover mechanism based on cuboid heavy piece

A hydraulic inversion, cuboid technology, applied in workpiece clamping devices, manufacturing tools, etc., can solve the problems of high labor intensity, potential safety hazards, and cumbersome transfer process, and achieve the goal of reducing potential safety hazards, shortening working hours, and reducing labor intensity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] In order to more clearly illustrate the technical solutions of the embodiments of the present invention, the following will briefly introduce the accompanying drawings that need to be used in the embodiments. Obviously, the accompanying drawings in the following description are some embodiments of the present invention. Ordinary technicians can also obtain other drawings based on these drawings on the premise of not paying creative work.

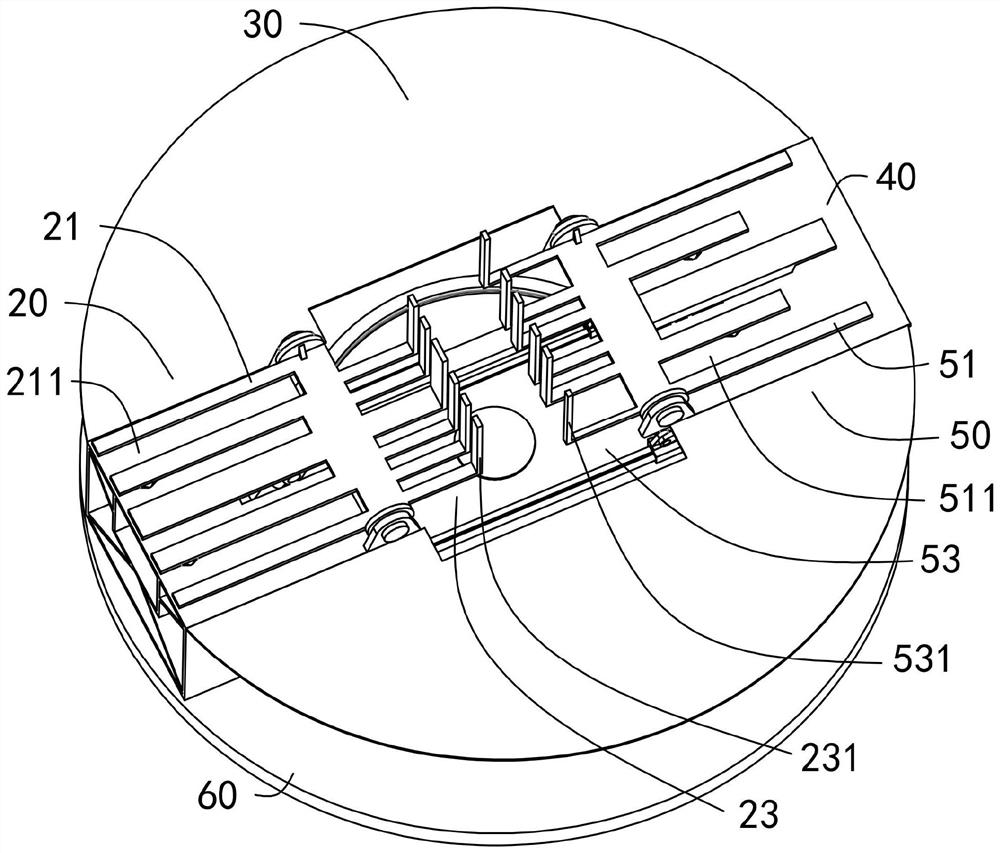

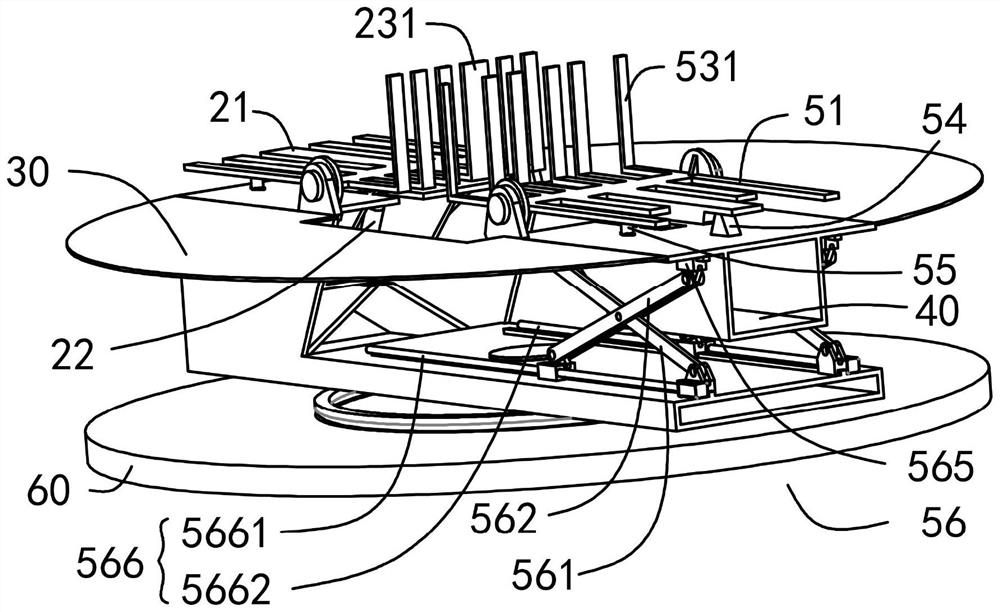

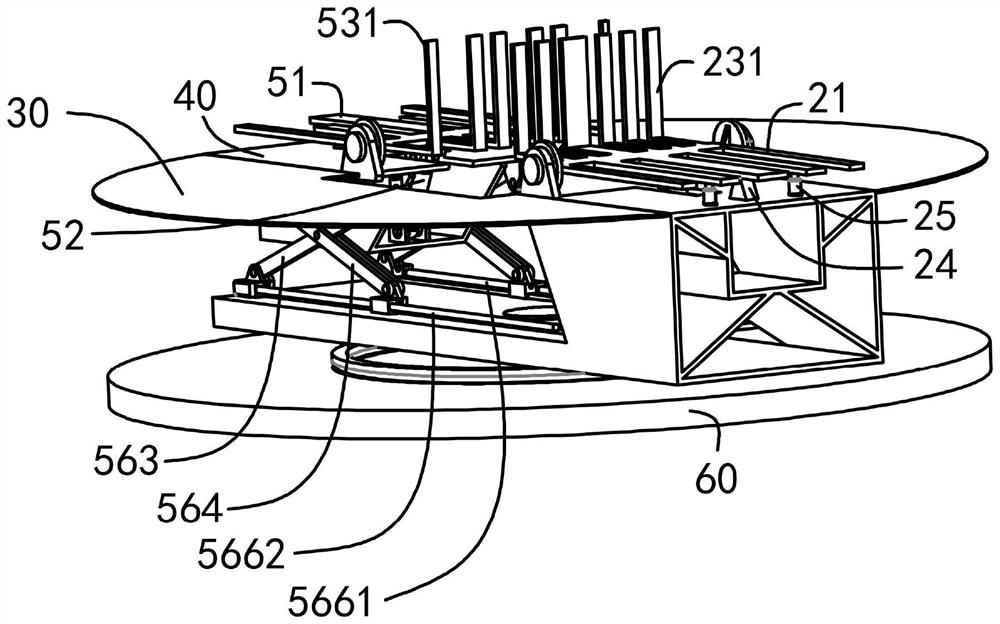

[0036] see Figure 1 to Figure 3, the embodiment of the present invention provides an inter-insertable half-pack type hydraulic turning mechanism based on cuboid weights, including a receiving assembly 20, a receiving table 30, an transferring table 40, and an transferring assembly 50, and the receiving assembly 20 includes a receiving plate 21 , the first driving hydraulic cylinder 22, the first comb tooth part 23, one end of the receiving plate 21 is a free end, the two sides of the other end of the receiving plate 21 are connected ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com