Digital servo control system and control method thereof

A control system and digital servo technology, applied in the field of servo control, can solve the problems of mutual occlusion of arrays, insufficient precision, and insufficient real-time performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

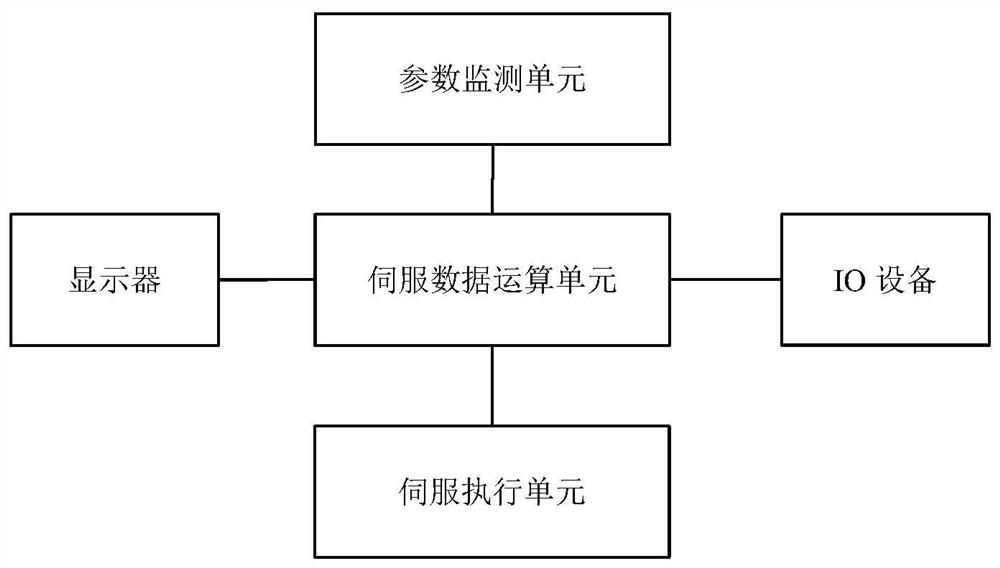

[0073] A digital servo control system, including a parameter monitoring unit, a servo execution unit, a display, and an IO device all connected to a servo data computing unit, wherein the parameter monitoring unit monitors the parameters required by the servo control system and transmits the data to the servo data computing unit , through internal specific control algorithm and operation analysis of control strategy, output control signal to servo execution unit, display and IO device display system data and operating system instructions respectively.

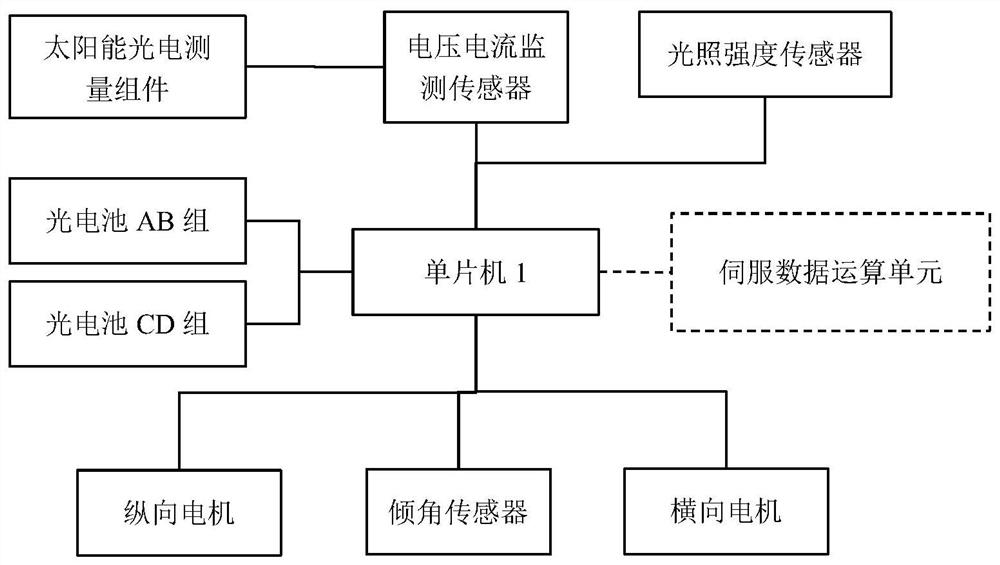

[0074] The parameter monitoring unit includes photocell AB groups, photocell CD groups, voltage and current monitoring sensors, light intensity sensors, horizontal motors, longitudinal motors and inclination sensors that are all connected to the single-chip microcomputer 1; wherein the photocell AB groups include two respectively arranged The photovoltaic cell A board and B board of the same specification above and below the sam...

Embodiment 2

[0083] A digital servo control system, including a parameter monitoring unit, a servo execution unit, a display, and an IO device all connected to a servo data computing unit, wherein the parameter monitoring unit monitors the parameters required by the servo control system and transmits the data to the servo data computing unit , through internal specific control algorithm and operation analysis of control strategy, output control signal to servo execution unit, display and IO device display system data and operating system instructions respectively.

[0084] The parameter monitoring unit includes photocell AB groups, photocell CD groups, voltage and current monitoring sensors, light intensity sensors, horizontal motors, longitudinal motors and inclination sensors that are all connected to the single-chip microcomputer 1; wherein the photocell AB groups include two respectively arranged The photovoltaic cell A board and B board of the same specification above and below the sam...

Embodiment 3

[0134] This embodiment is a simplified solution based on the standard solution of embodiment 1 or embodiment 2, with the purpose of reducing the number of system components, reducing the volume of the system, simplifying installation steps and further reducing supporting costs.

[0135] The main simplification scheme is as follows:

[0136] Solution 1: Use low-cost and small-volume photosensitive sensors for the photocell AB group and photocell CD group, and pay attention to the selection of high-precision ones, as long as they meet the functional and precision requirements;

[0137] Solution 2: The inclination sensors of the parameter monitoring unit and the servo execution unit both use multi-axis inclination sensors, which further reduces the number and volume of parts and facilitates installation and layout;

[0138] Solution 3: For the part involving the motor, a motor with a higher integration level and a built-in encoder can be used on the premise of meeting the requireme...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com