A non-destructive testing method for micro-defects in long-distance thin-plate structures

A thin-plate structure and non-destructive testing technology, applied in the direction of measuring devices, processing detection response signals, instruments, etc., can solve the problems of difficult detection of micro-defects in long-distance thin-plate structures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

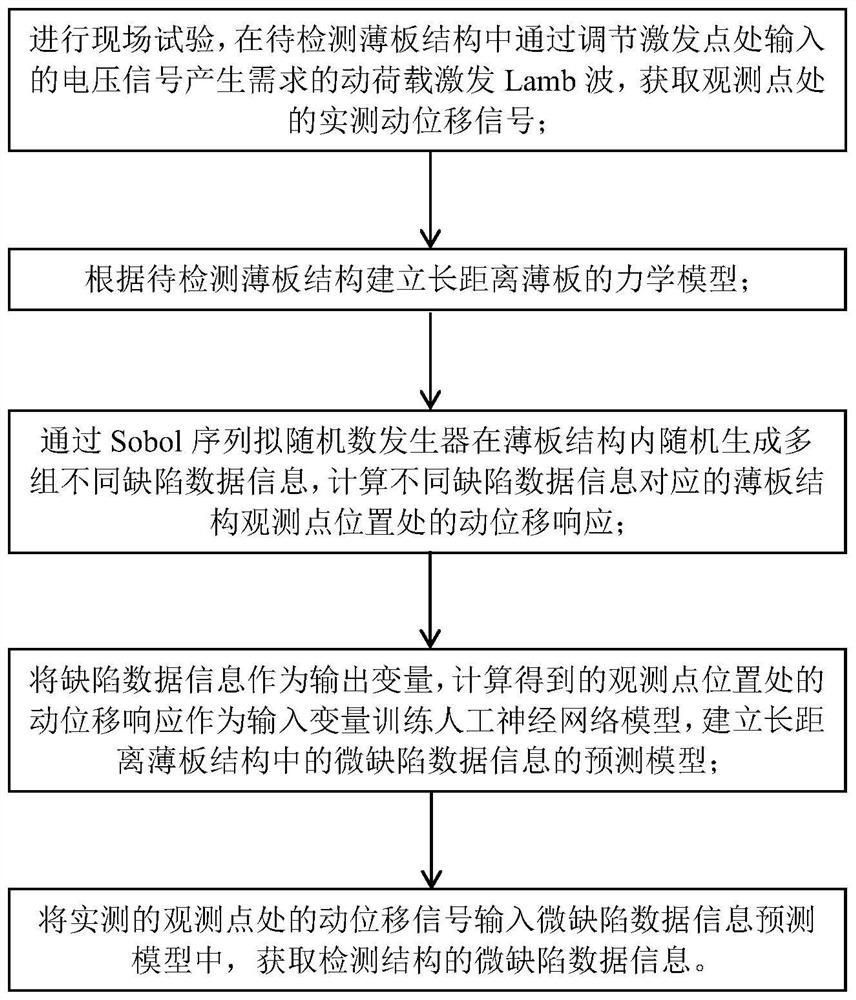

[0029] like figure 1 As shown, a non-destructive testing method for long-distance thin plate structure micro-defects includes the following steps:

[0030] A non-destructive testing method for long-distance thin plate structure micro-defects, comprising the following steps:

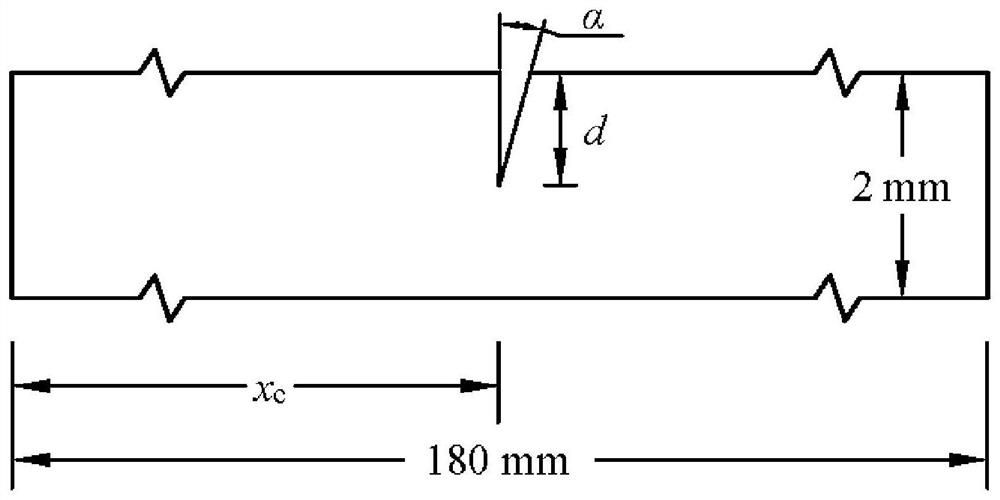

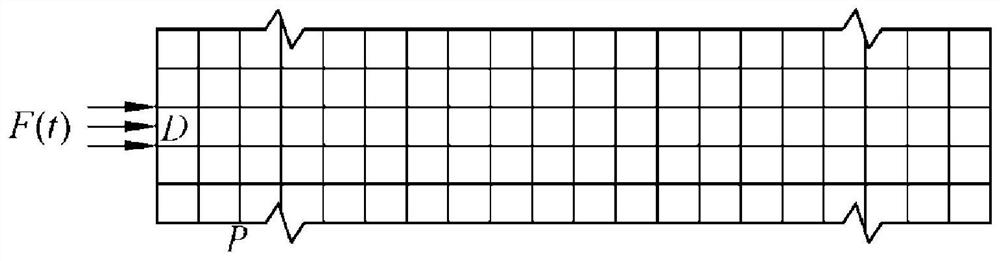

[0031] Step 1: Determine the geometric dimensions and material properties of the long-distance thin plate to be measured, the positions of the Lamb wave excitation point and observation point on the long-distance thin plate to be measured, and the pre-applied dynamic load at the excitation point. like figure 2 , the geometric dimensions of the long-distance sheet to be measured in this embodiment are: length 180mm, thickness 2mm, elastic modulus E=200GPa, Poisson’s ratio v=0.3, density ρ=7850kg / m 3 , there is a micro-crack-like defect somewhere on the upper part of the long-distance thin plate structure to be measured, but the crack tip position x of the specific crack-like micro-defect cannot be predi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| elastic modulus | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com