An electroslag pressure welding welding package height detection device and using method

A height detection device and pressure technology, applied in the direction of measuring devices, mechanical measuring devices, mechanical devices, etc., can solve the problems of inability to directly observe the number, large measurement error, and inconvenient measurement of the welding package, so as to achieve accurate and intuitive detection data , low requirements for environmental use, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

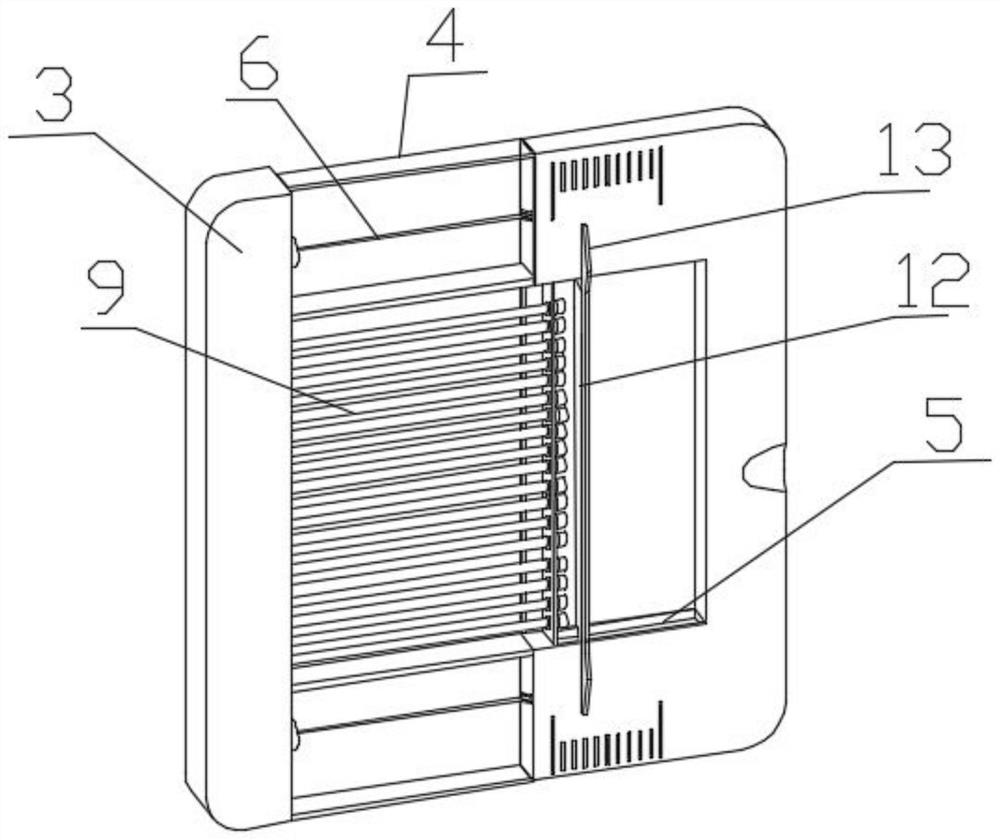

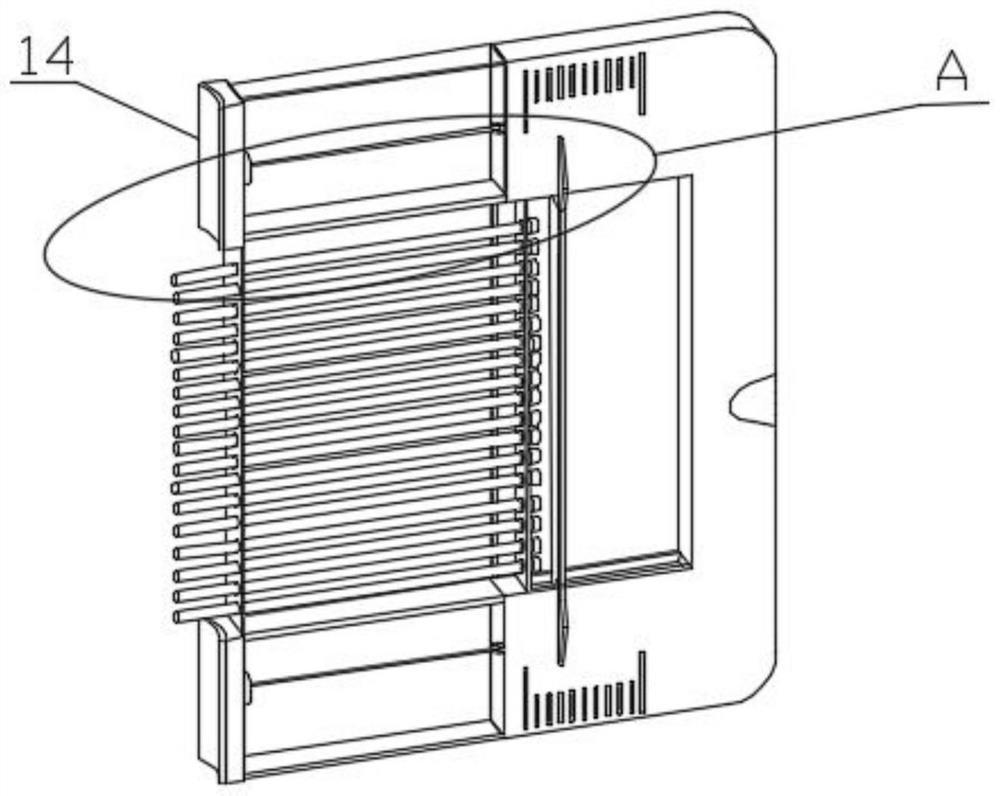

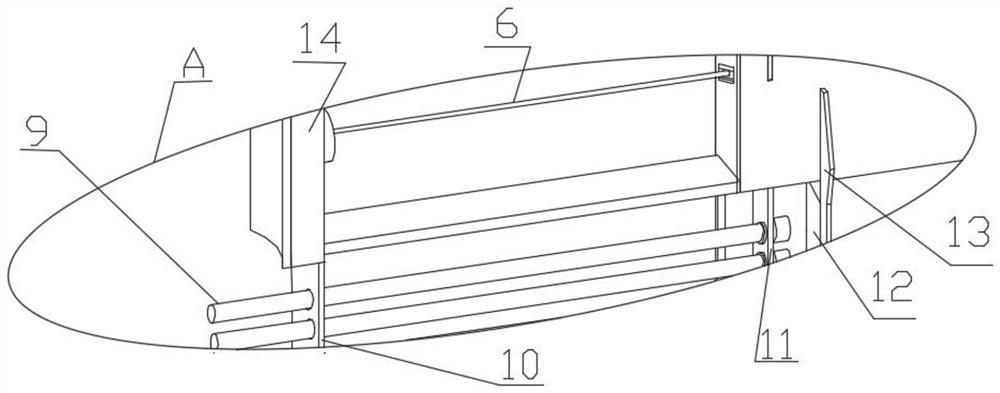

[0039] Such as Figure 1 to Figure 6 Shown: an electroslag pressure welding welding bag height detection device, including a steel bar 1 and a welding bag 2 to be detected on the steel bar 1, and also includes a hand-held part, a connecting part, a protective shell 3 and a reset part, the hand-held part is connected to the The connecting part is marked with the measuring range on the hand-held part, and the connecting part includes the connection shell 4, the bonding part and the pointing part, and the connection shell 4 is fixedly connected with the hand-held part;

[0040] The fitting part is located inside the connection shell 4, and the fitting part is suitable for fitting the welding package 2 to be detected. The pointing part is suitable for pointing to the measuring range and displaying the position of the fitting part. The other end of is located in the handle, and the reset piece is suitable for connecting the connection shell 4 and the pointing piece;

[0041] The p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com