Heat dissipation mechanism of automatic bottom sealing machine for quartz glass sleeves

A technology of quartz glass and heat dissipation mechanism, which is applied in glass forming, glass reshaping, glass manufacturing equipment, etc., can solve the problem of slow cooling speed and achieve good heat dissipation effect

Pending Publication Date: 2021-01-05

连云港汇德石英玻璃有限公司

View PDF0 Cites 3 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0004] The purpose of the present invention is to solve the defect in the prior art that "when the bottom is automatically sealed, the bottom is burned by a flamethrower. After the bottom is sealed, the bottom of the tube is in a high temperature state, and it needs to be naturally cooled and shaped, and the cooling speed is relatively slow", thus proposing A heat dissipation mechanism of an automatic bottom sealing machine for quartz glass sleeves

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

[0017] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some, not all, embodiments of the present invention.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

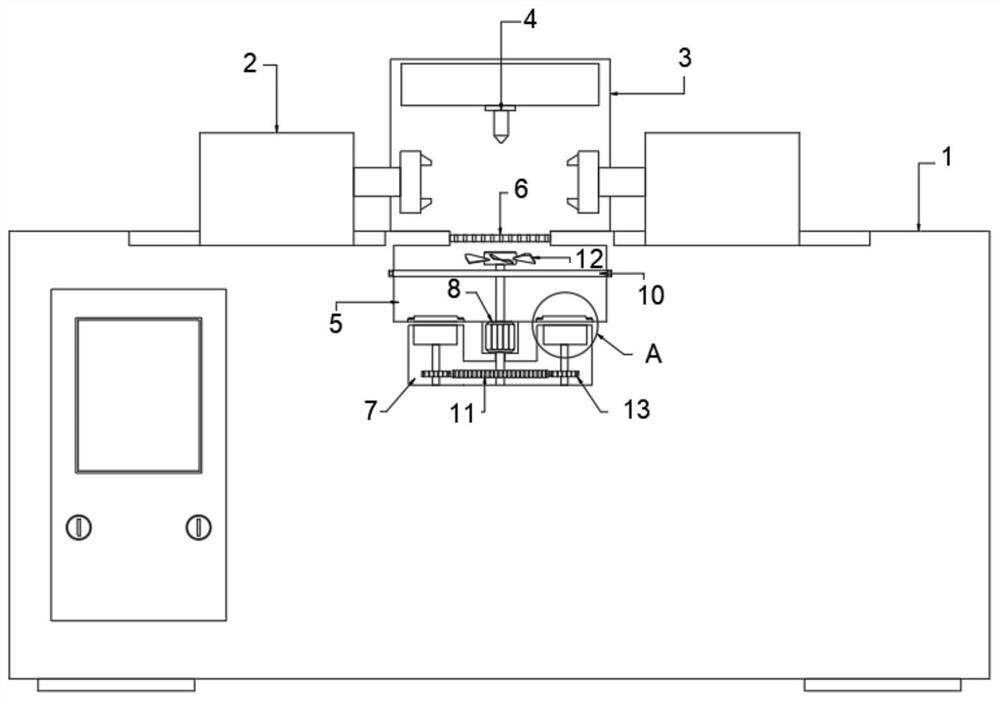

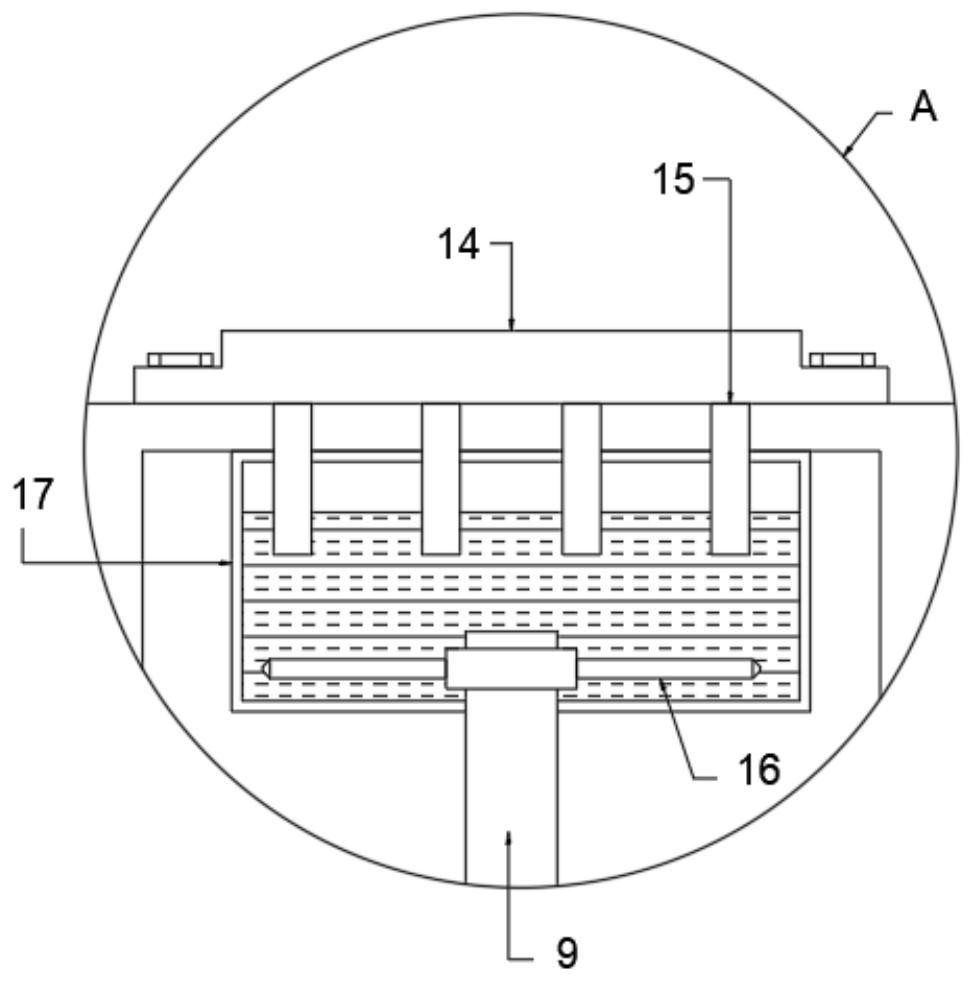

The invention discloses a heat dissipation mechanism of an automatic bottom sealing machine for quartz glass sleeves. The heat dissipation mechanism comprises a bottom sealing machine body, wherein driving seats are symmetrically connected to the bottom sealing machine body in a sliding manner, a fixed seat is fixedly connected to the bottom sealing machine body, a flamethrower is arranged on thefixed seat, a first cavity and a second cavity are respectively formed in the bottom sealing machine body, semiconductor chilling plates are symmetrically and fixedly installed on the bottom wall of the first cavity, heat conduction mechanisms are arranged on the bottom sides of the semiconductor chilling plates, and a double-shaft motor is fixedly installed in the bottom sealing machine body. According to the heat dissipation mechanism, a first output shaft is driven by the double-shaft motor to rotate quickly, so that a fan rotates to blow air, meanwhile, the temperature of air in the firstcavity is reduced quickly under the action of the semiconductor chilling plates, cold air flow dried by a drying plate is blown out through the fan, a glass pipeline with the bottom sealed is cooled and shaped quickly, and the heat dissipation effect is better.

Description

technical field [0001] The invention relates to the technical field of quartz glass sleeves, in particular to a heat dissipation mechanism of an automatic bottom sealing machine for quartz glass sleeves. Background technique [0002] Quartz sleeve is a special glass containing only silicon dioxide. Due to different types, processes, and raw materials, they are basically called silicate glass, quartz sleeve, fused quartz, fused quartz, synthetic fused quartz, and transparent, translucent, and opaque quartz without a clear concept, according to the process method. , use and appearance to classify, such as fused transparent quartz casing, continuous fused quartz casing, gas refining transparent quartz casing, synthetic quartz casing and so on. [0003] The existing quartz glass casing is sealed by an automatic back-sealing machine. The three-jaw chuck of the back-sealing machine drives the glass sleeve to rotate, and then uses a flamethrower to burn and seal the back. Cooling...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): F25D31/00F25D17/06F25D17/04F25B21/02C03B23/207

CPCC03B23/207F25B21/02F25B2321/02F25D17/04F25D17/06F25D31/00

Inventor 乔庆功孙兴勇

Owner 连云港汇德石英玻璃有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com