Vacuum blow-down valve

A vacuum sewage and valve body technology, applied in sliding valves, valve details, valve devices, etc., can solve the problems of low sewage discharge efficiency and conveying efficiency, inconvenient condensate discharge, poor structural performance, etc., and reduce work efficiency and service life. , Satisfy the effect of relative dryness and good conveying efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0061] Below in conjunction with specific embodiment, content of the present invention is described in further detail:

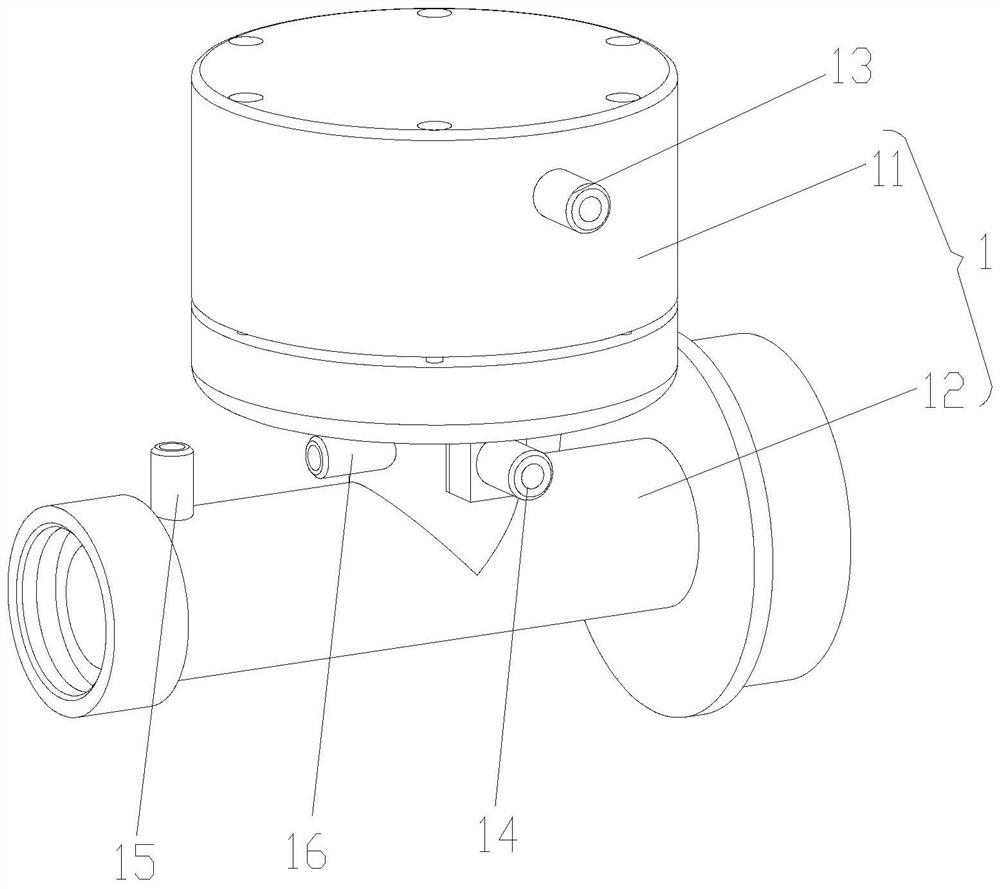

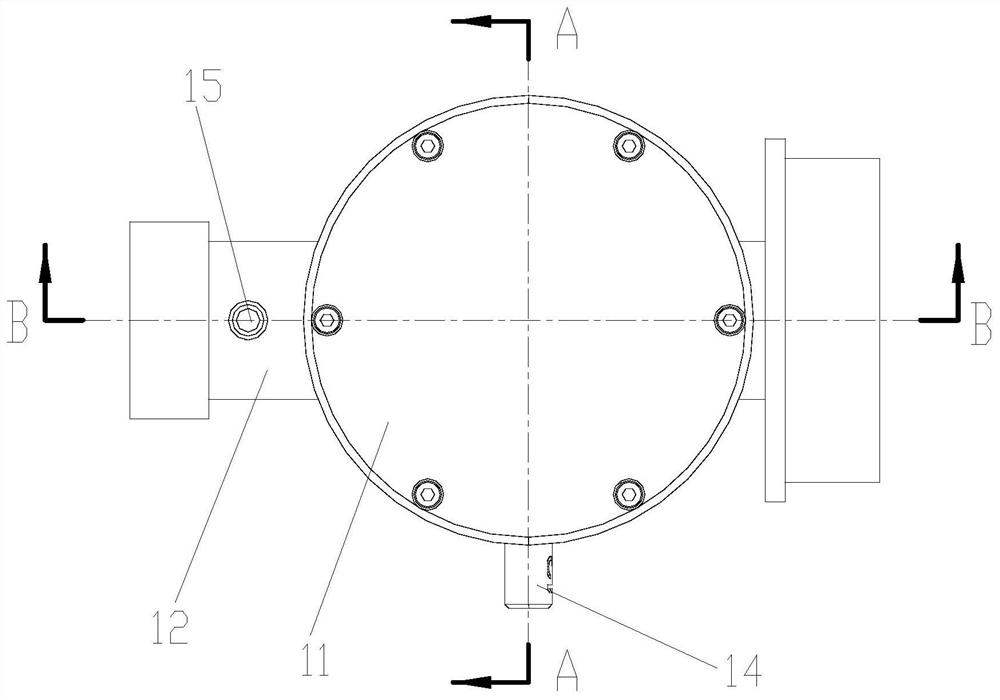

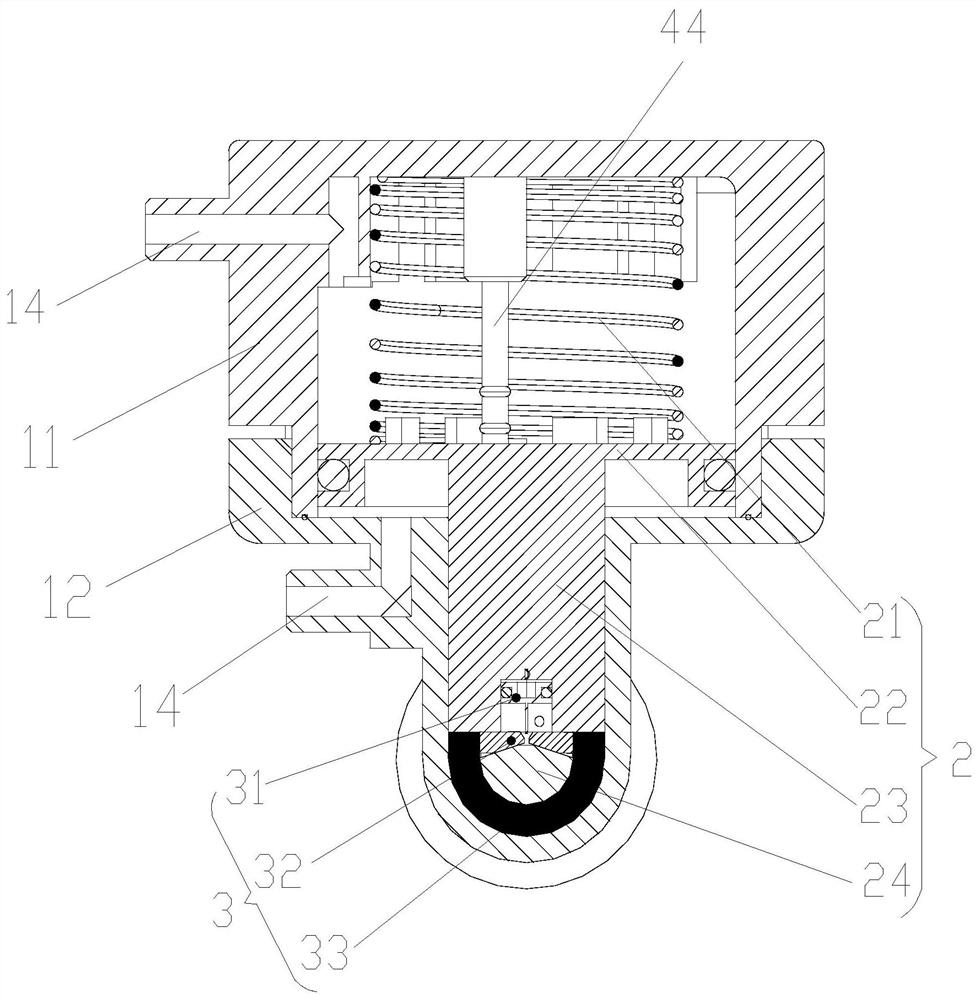

[0062] Such as Figure 1-5 As shown, a vacuum blowdown valve is mainly used in vacuum toilets. Its structure includes a valve body 1, a main valve core assembly 2 arranged inside the valve body 1 for realizing the on-off of the valve body 1, and a main valve core assembly arranged on the main body 1. 2 The internal valve core assembly 3 used to realize the disconnection and sealing inside the valve body 1, and the exhaust pipeline 4 and the one-way valve assembly 41 arranged on the inner side of the main body valve core assembly 2; simply, the valve body 1 has A communication flow channel 18, and the inside of the valve body 1 is used for intermittently introducing air or forming a vacuum; the main body valve core assembly 2 is set in the valve body 1, and realizes the connection to the communication flow channel 18 through the ventilation state inside the v...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com