Efficient and energy-saving type anti-overload hydroelectric generation equipment

A high-efficiency, energy-saving, and overload-proof technology is applied in hydropower, mechanical equipment, and electromechanical devices. It can solve problems such as the influence of water flow velocity and the generator cannot be actively adjusted, so as to improve service life, avoid overheating damage, and avoid overload damage. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

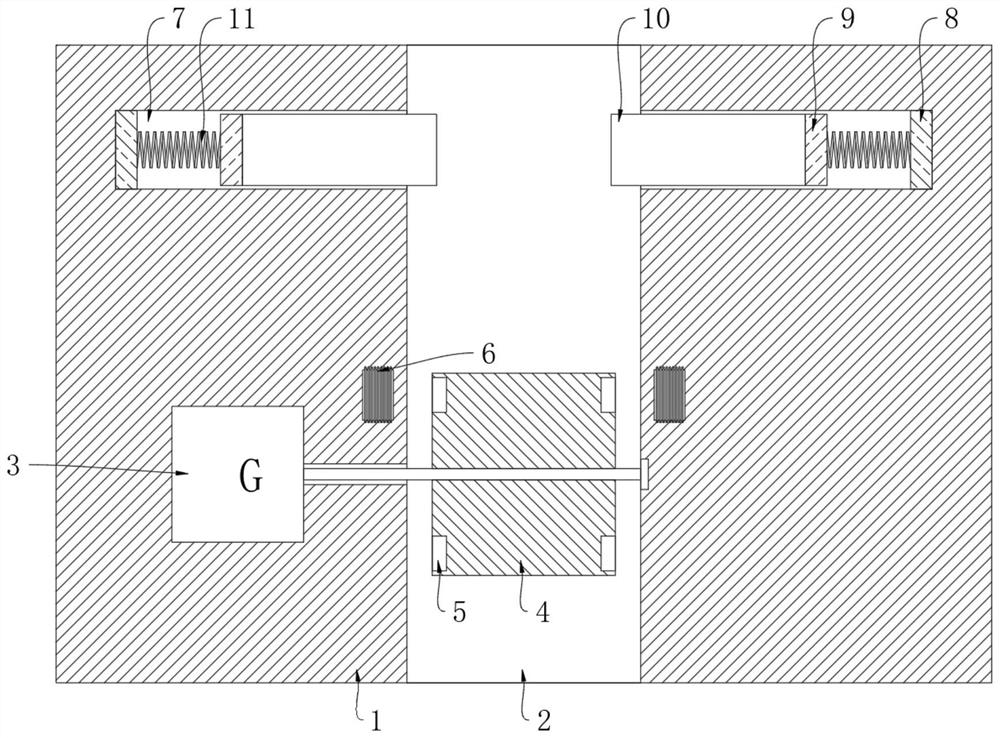

[0021] refer to figure 1 , a high-efficiency energy-saving anti-overload hydroelectric power generation equipment, including an installation platform body 1 and a generator body 3 installed in the installation platform body 1, and a circulation groove 2 for water flow is vertically opened on the installation platform body 1, and the circulation groove A plurality of fan blades 4 are installed in the 2 through the uniform rotation of the rotating shaft, and one end of the rotating shaft is connected to the input end of the generator body 3, and each fan blade 4 is symmetrically provided with a first permanent magnet block 5, and the installation platform body 1 An induction coil 6 corresponding to the first permanent magnet block 5 is symmetrically provided;

[0022] The upper side of the groove wall of the circulation groove 2 is symmetrically provided with a storage groove 7, and an electromagnet 8 is fixedly installed on the opposite groove wall of the two storage grooves 7,...

Embodiment 2

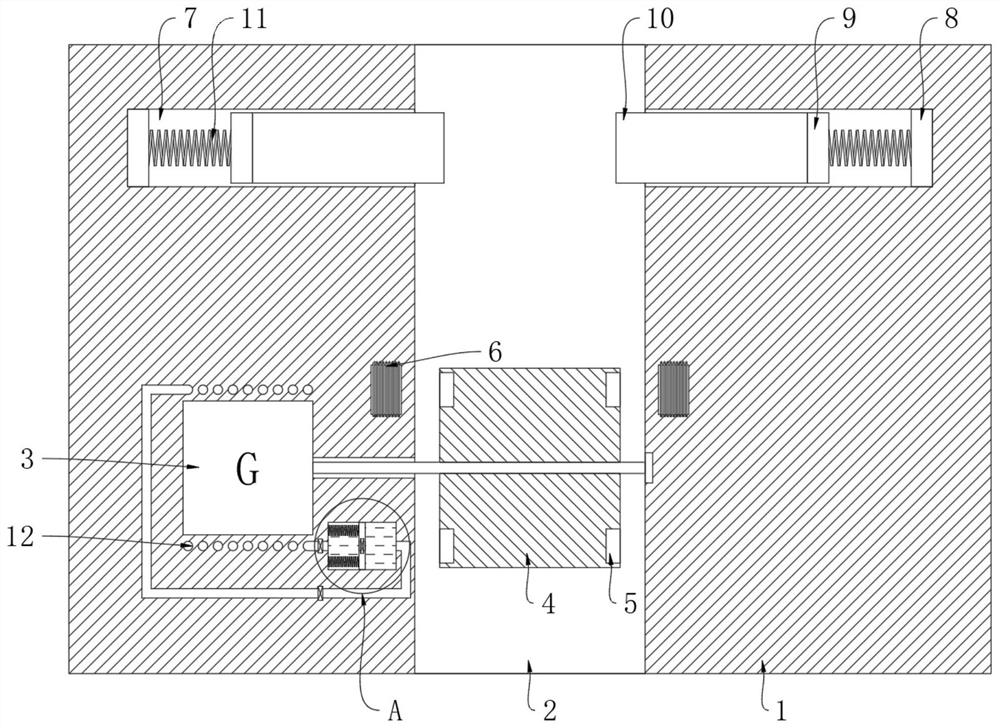

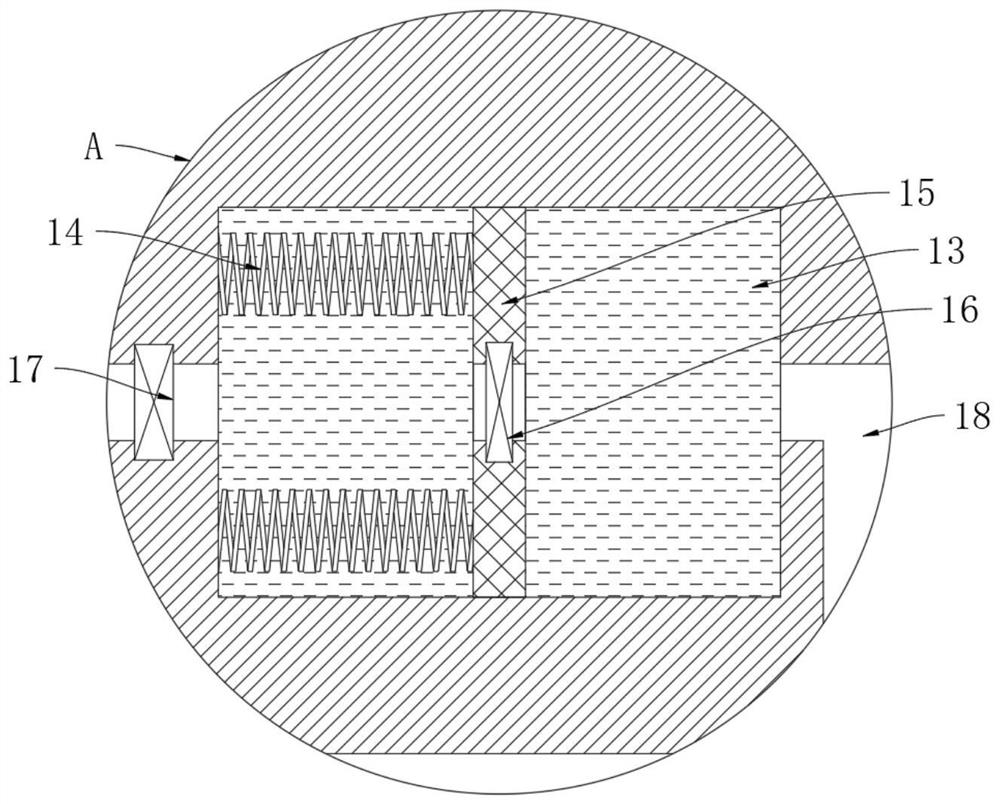

[0025] refer to Figure 2-3 , the present embodiment differs from Embodiment 1 in that: the outer cover of the generator body 3 is provided with a heat exchange coil 12; A piston block 15 made of ferromagnetic material is vertically sealed and slidably connected by a return spring 14, and the piston block 15 separates the cooling tank 13 into a driving area and a driven area;

[0026] A connecting pipe 16 is provided on the piston block 15, a one-way drain pipe 18 is connected between the driving area and the input end of the heat exchange coil 12, and a one-way drain pipe 18 is connected between the driven area and the output end of the heat exchange coil 12. The one-way liquid inlet pipe 17, the heat exchange coil 12, the cooling tank 13, the one-way liquid inlet pipe 17 and the one-way liquid discharge pipe 18 are all filled with cooling liquid, the connecting pipe 16, the one-way liquid inlet pipe 17 and the one-way The first one-way valve, the second one-way valve and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com