Lubricating oil nozzle with filtering function

A technology of lubricating oil nozzles and nozzles, which is applied in the direction of engine lubrication, turbine/propulsion device lubrication, and lubricating parts, etc., to achieve the effect of ensuring the speed and flow of lubricating oil injection, ensuring safe work, and simple filtering

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] In order to make the purpose, technical solution and advantages of the application more clear, the technical solution in the embodiment of the application will be described in more detail below in conjunction with the drawings in the embodiment of the application.

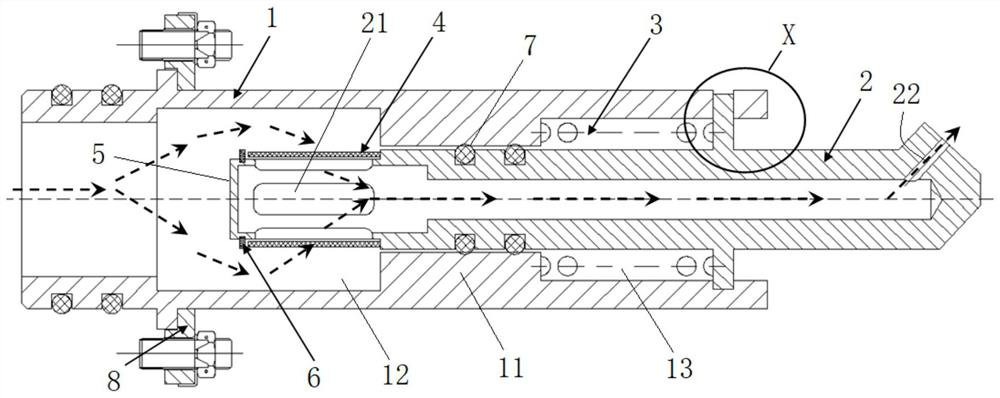

[0024] Such as figure 1 As shown, the lubricating oil nozzle with filtering function provided by the present application mainly includes: a nozzle housing 1 , a nozzle 2 , a spring 3 and a filter screen 4 .

[0025] The nozzle housing 1 is the main load-bearing part of the lubricating oil nozzle. It has a channel inside. In the middle of the channel is a support part 11 composed of a wall with a small inner diameter. Spring chamber 13.

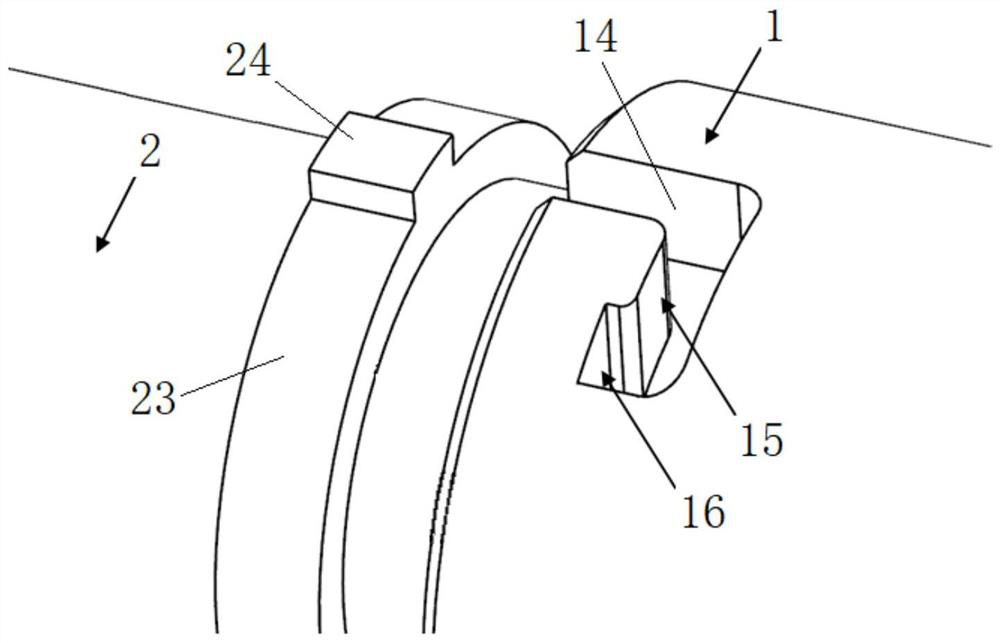

[0026] The left part of the nozzle 2 protrudes into the channel and is supported by the supporting part 11 , and the spray hole 22 of the right part exposes the nozzle housing 1 . A plurality of radially opened filter holes 21 are arranged on the left side of the nozzle 2 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com