High-temperature and high-pressure shale reservoir imbibition evaluation device

A high-temperature, high-pressure, evaluation device technology, which is applied in wellbore/well components, measurement, production fluid, etc., can solve the problems of complex process, no consideration of oil loss, experimental error, etc., and achieve the effect of accurate test results and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

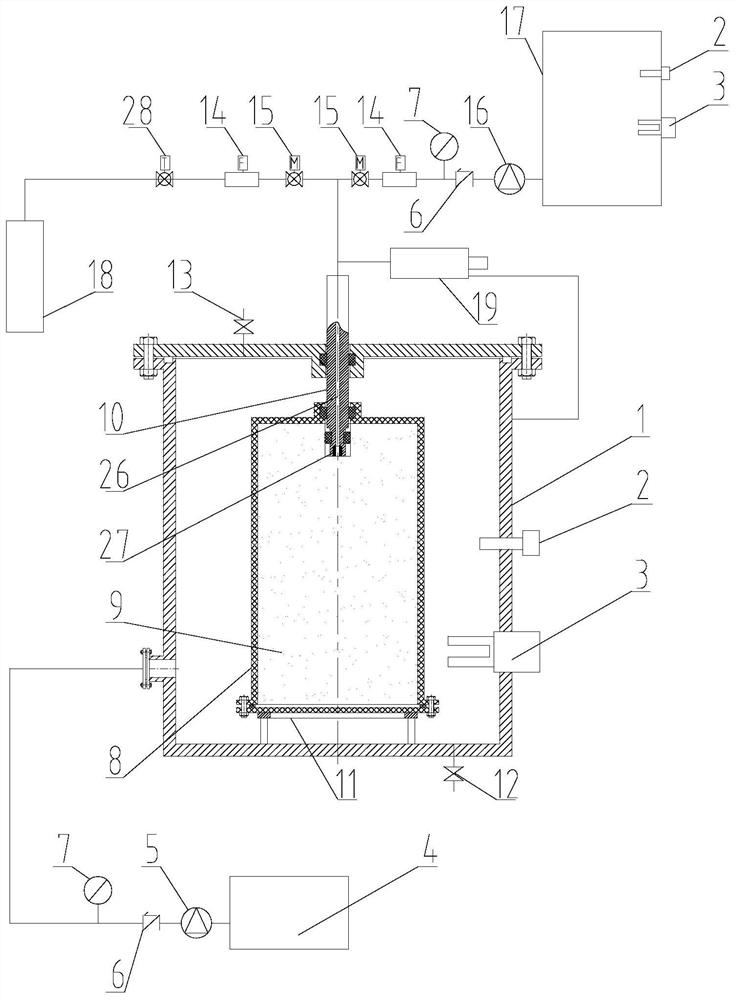

[0020] The present invention will be further described below in conjunction with accompanying drawing:

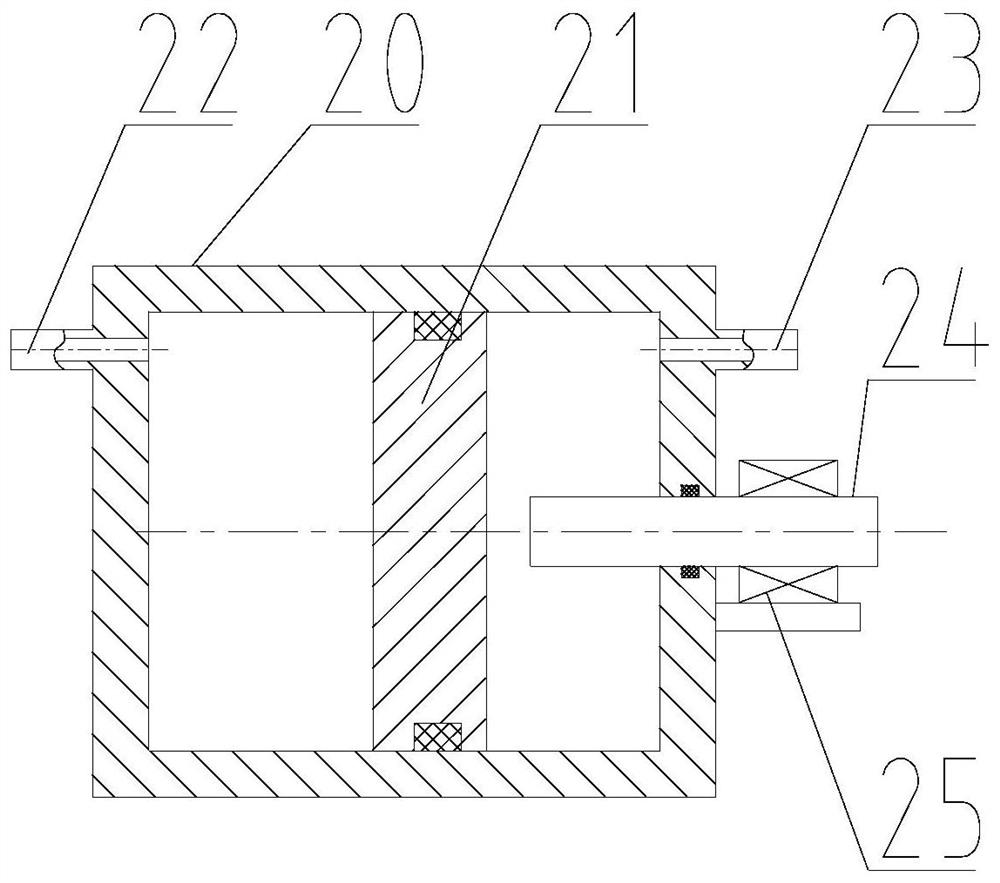

[0021] Depend on figure 1 to combine figure 2 As shown, the high-temperature and high-pressure shale reservoir imbibition evaluation device includes a pressure tank 1. The pressure tank 1 is a closed container with a flange cover on the upper part of a steel cylinder. The upper part of the pressure tank 1 is provided with an exhaust valve 13. The bottom of the pressure tank 1 is provided with a drain valve 12, the bottom of the pressure tank 1 is provided with a bracket 11, and a compression sleeve 8 is placed on the bracket 11. The bottom of the compression sleeve 8 is provided with a flange cover to seal and connect to form a closed container. The compression sleeve 8 is pressure-resistant rubber. A core 9 is installed in the compression sleeve 8, a counterbore is cut in the center of the core 9, a fracturing tube 10 is inserted in the counterbore of the core 9, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com