Method for improving desulfurization effect of single-blown granular magnesium

A granular magnesium and high-level technology, applied in the field of iron and steel metallurgy, can solve the problems of difficult to remove clean, can not meet the development requirements of special varieties, etc., to improve the desulfurization effect, improve the slag removal effect, and avoid the effect of returning sulfur.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

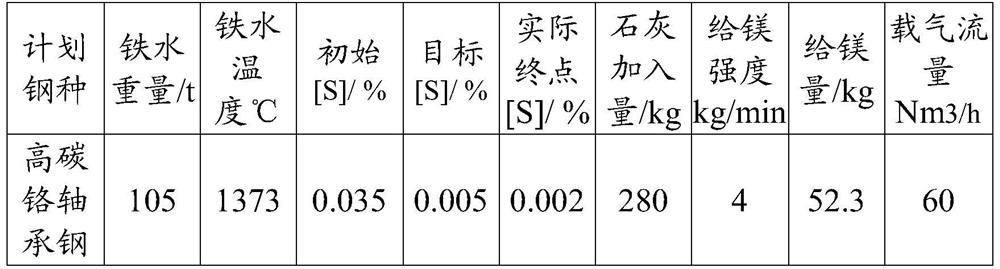

[0018] Before the pretreatment of molten iron, the condition of molten iron is shown in Table 1.

[0019] Table 1 Example 1 Table of molten iron components before desulfurization

[0020] chemical composition C,% Si,% Mn,% P,% S,% Ti,% T,℃ weight, t Before desulfurization 4.07 0.59 0.29 0.119 0.039 0.060 1326 105 Desulfurization target - - - - 0.005 - 1250 -

[0021] A method for improving the desulfurization effect of single-blown granular magnesium, comprising the steps of:

[0022] (1) Slagging before desulfurization:

[0023] Start the tipping vehicle to tilt the molten iron ladle to a suitable position (thin slag molten iron is about 8m away from the ladle edge, and slag lump molten iron is about 15cm away from the ladle edge), and use a pneumatic slag removal gun to cooperate with slag removal. Control the scraper of the slag scraper, and carry out the slag removal operation in the slag tank placed on the slag tank tru...

Embodiment 2

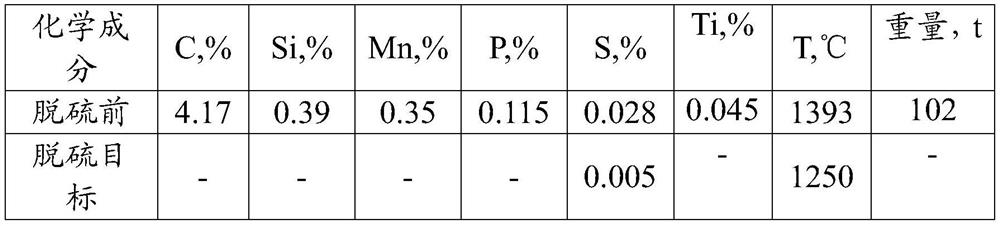

[0032] Before the pretreatment of molten iron, the condition of molten iron is shown in Table 3.

[0033] Table 3 Example 2 Desulfurization before molten iron composition table

[0034]

[0035] (1) Slagging before desulfurization:

[0036] Start the tipping vehicle to tilt the molten iron ladle to a suitable position (thin slag molten iron is about 8m away from the ladle edge, and slag lump molten iron is about 15cm away from the ladle edge), and use a pneumatic slag removal gun to cooperate with slag removal. Control the scraper of the slag scraper, and carry out the slag removal operation in the slag tank placed on the slag tank truck. The slag removal time after desulfurization is required to be 6 minutes. The amount of slag on the molten iron surface is ≤0.05%, to ensure that the slag is cleaned.

[0037] (2) Lime addition: After removing slag in the early stage of molten iron, use a thickening slag agent device, first lower the feeding chute to the lower position, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com