Novel nanoscale liquid titanium dioxide for coating

A nano-scale liquid and titanium dioxide technology, applied in the field of titanium dioxide, can solve the problems of easy wear, poor coating rate, lack of flame retardancy, etc., achieve good wear resistance, ensure coating effect, and improve coating rate Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

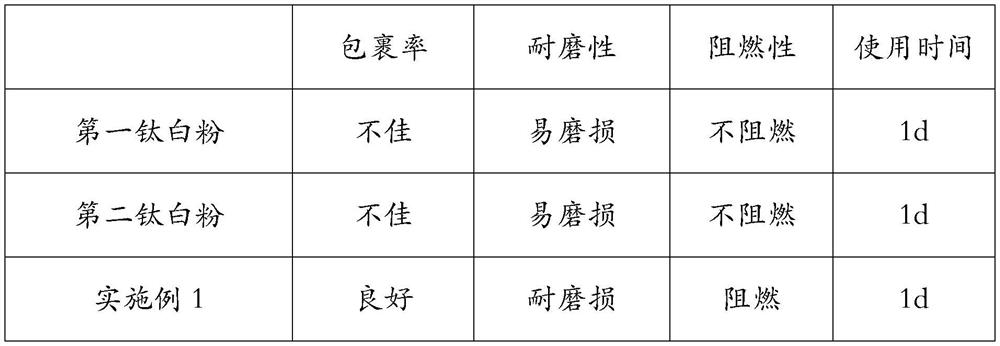

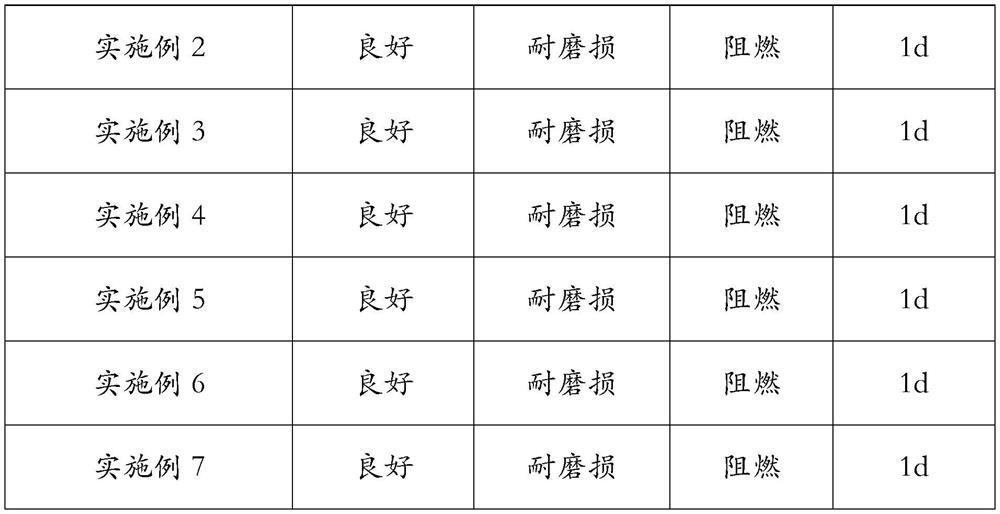

Examples

Embodiment 1

[0022] A new type of nanoscale liquid titanium dioxide for coatings, comprising the following raw materials in parts by weight: 60 parts of titanium dioxide particles, 100 parts of calcium carbonate powder, 50 parts of wear-resistant and acid-resistant powder, 660 parts of deionized water, 6 parts of activator, flame retardant 8 parts of agent, titanium dioxide has the characteristics of non-toxicity, best opacity, best whiteness and brightness, and it is an important ingredient in the preparation of liquid titanium dioxide. Calcium carbonate is an inorganic compound without harmful ingredients. Calcium powder is treated with surface activation. The activator has a grinding aid effect, which promotes the generation of activated ions on the surface of calcium carbonate powder, thereby improving the coating rate of titanium dioxide powder on calcium carbonate nano-powder. The added wear-resistant and acid-resistant powder makes The prepared nano-scale liquid titanium dioxide has ...

Embodiment 2

[0032] A new type of nanoscale liquid titanium dioxide for coatings, including the following raw materials in parts by weight: 80 parts of titanium dioxide particles, 120 parts of calcium carbonate powder, 70 parts of wear-resistant and acid-resistant powder, 880 parts of deionized water, 16 parts of activator, flame retardant 20 parts of titanium dioxide. Titanium dioxide has the characteristics of non-toxicity, best opacity, best whiteness and brightness. It is an important ingredient in the preparation of liquid titanium dioxide. Calcium carbonate is an inorganic compound without harmful ingredients. Calcium powder is treated with surface activation. The activator has a grinding aid effect, which promotes the generation of activated ions on the surface of calcium carbonate powder, thereby improving the coating rate of titanium dioxide powder on calcium carbonate nano-powder. The added wear-resistant and acid-resistant powder makes The prepared nano-scale liquid titanium diox...

Embodiment 3

[0042]A new type of nanoscale liquid titanium dioxide for coatings, including the following raw materials in parts by weight: 58 parts of titanium dioxide particles, 98 parts of calcium carbonate powder, 48 parts of wear-resistant and acid-resistant powder, 658 parts of deionized water, 8 parts of activator, flame retardant 10 parts of titanium dioxide. Titanium dioxide has the characteristics of non-toxicity, best opacity, best whiteness and brightness. It is an important ingredient in the preparation of liquid titanium dioxide. Calcium carbonate is an inorganic compound without harmful ingredients. Calcium powder is treated with surface activation. The activator has a grinding aid effect, which promotes the generation of activated ions on the surface of calcium carbonate powder, thereby improving the coating rate of titanium dioxide powder on calcium carbonate nano-powder. The added wear-resistant and acid-resistant powder makes The prepared nano-scale liquid titanium dioxide...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com