Stator for motor or electric generator

A technology for generators and motors, which is applied to the shape/style/structure of winding conductors, the shape/style/structure of magnetic circuits, and static parts of magnetic circuits. And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

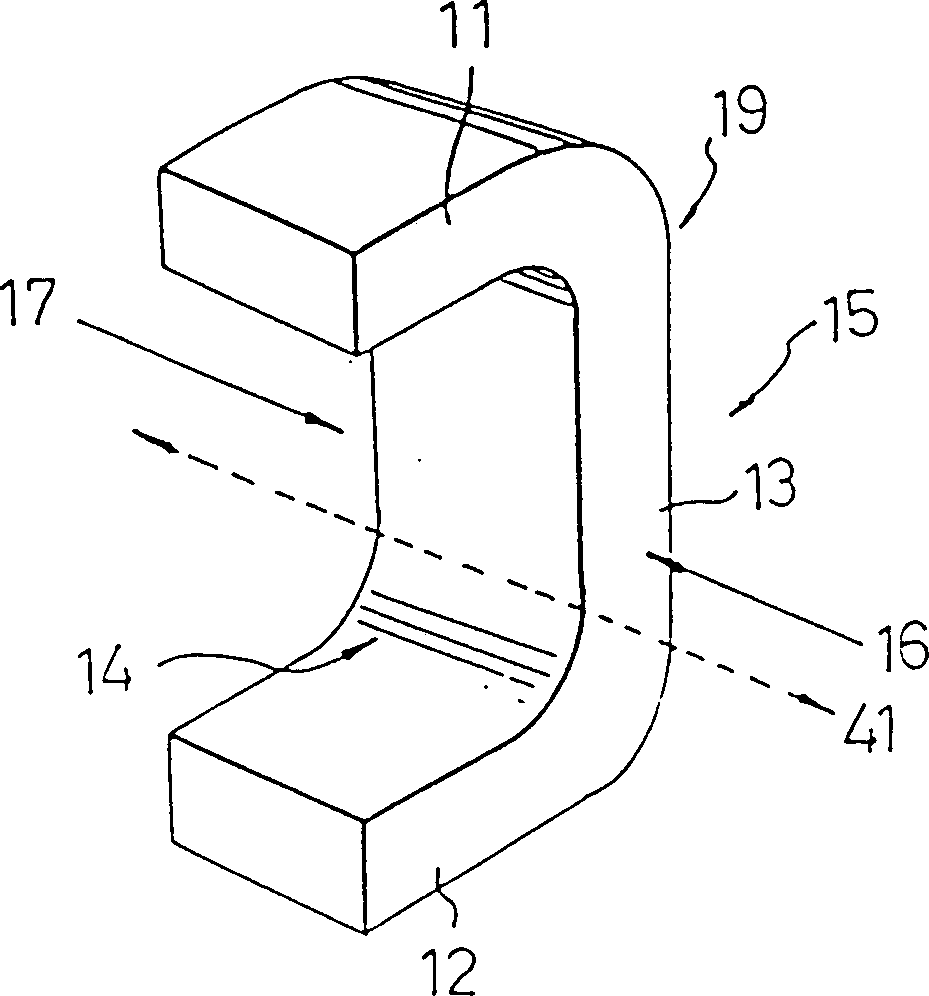

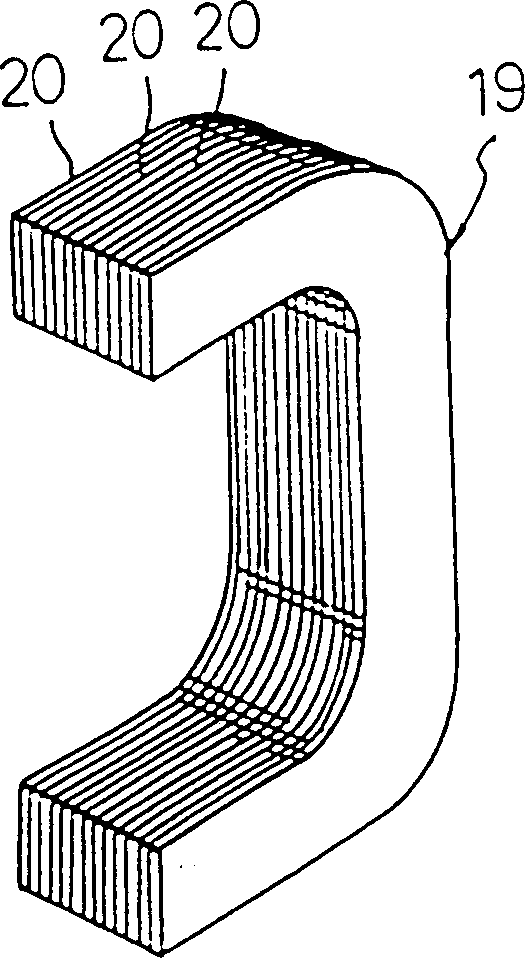

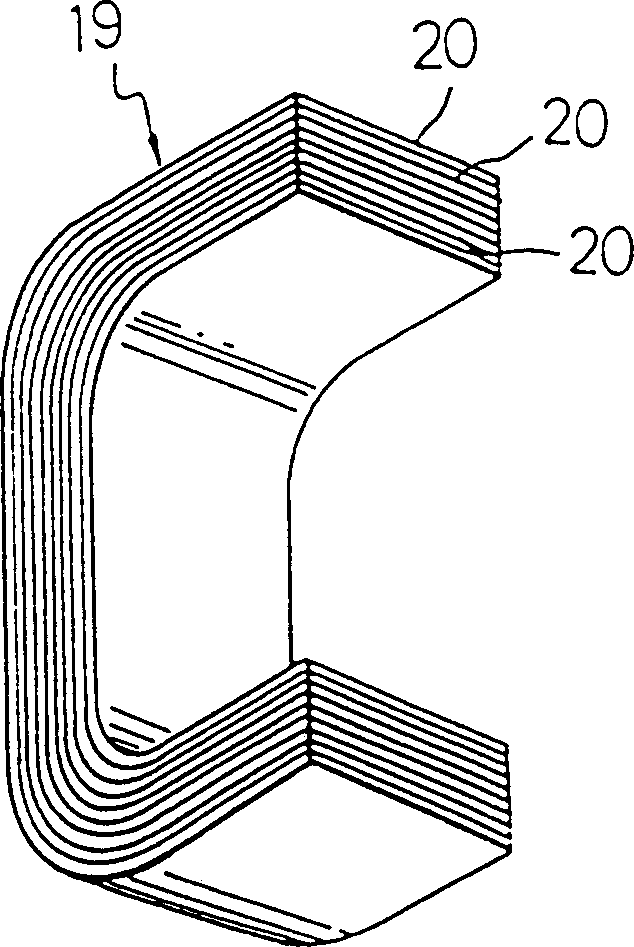

[0042] Please refer to FIG. 4 , which shows a basic form of a stator 90 for a motor or generator according to the present invention. This embodiment has three stator units 10 , wherein the stator unit 10 mainly includes a columnar body 19 and a coil 30 . For column 19, please also refer to figure 1 , for the convenience of the following description, the more detailed definition of the columnar body 19 is as follows. The columnar body 19 extends longitudinally from its top side 16 to its bottom side 17, the extending direction is defined as the longitudinal axis 41, and the columnar body 19 is roughly divided into a first end zone 11, a second end zone 12 and a middle section Zone 13, wherein the first end zone 11 and the second end zone 12 are respectively connected to both sides of the middle zone 13 (the N pole and the S pole are formed after the coil is wound and energized), and approach the inner side 14 of the monomer 10, and the inner side The opposite side of 14 forms...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com