Method for recycling residual concrete and preparing cement bricks by utilizing recycled materials and device thereof

A technology of cement bricks and recycled materials, which is applied in the direction of sustainable waste treatment, solid waste management, and climate sustainability. It can solve the problems of inferior clay bricks, aesthetic impact, and cracks on the wall, so as to improve economic value and improve The effect of economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0056] The recovery of the residual concrete and the method for preparing cement bricks by using the recycled materials comprise the following steps:

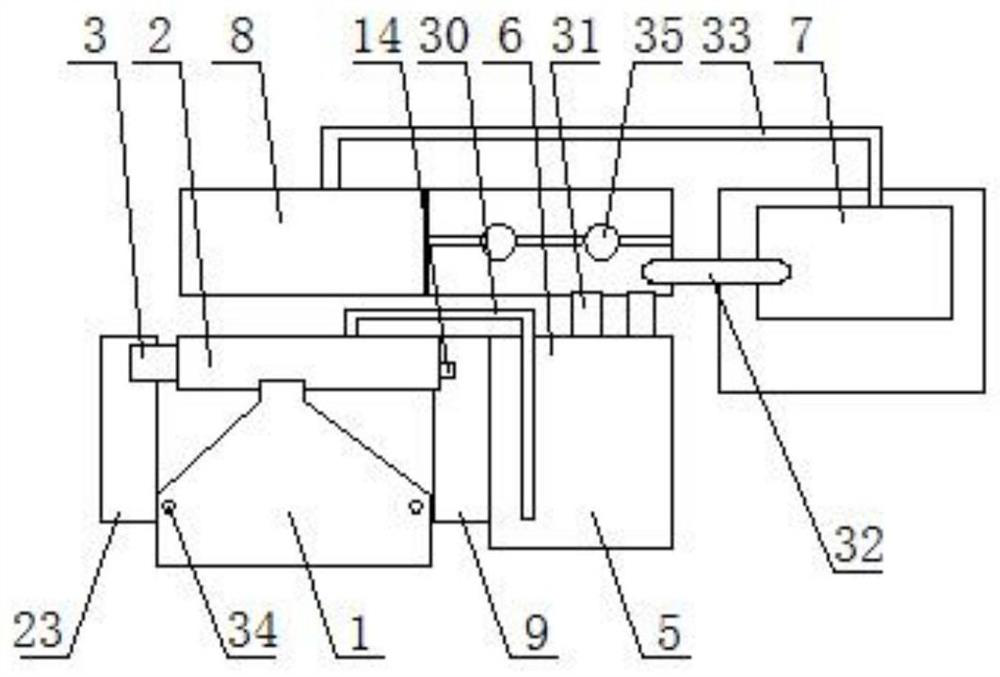

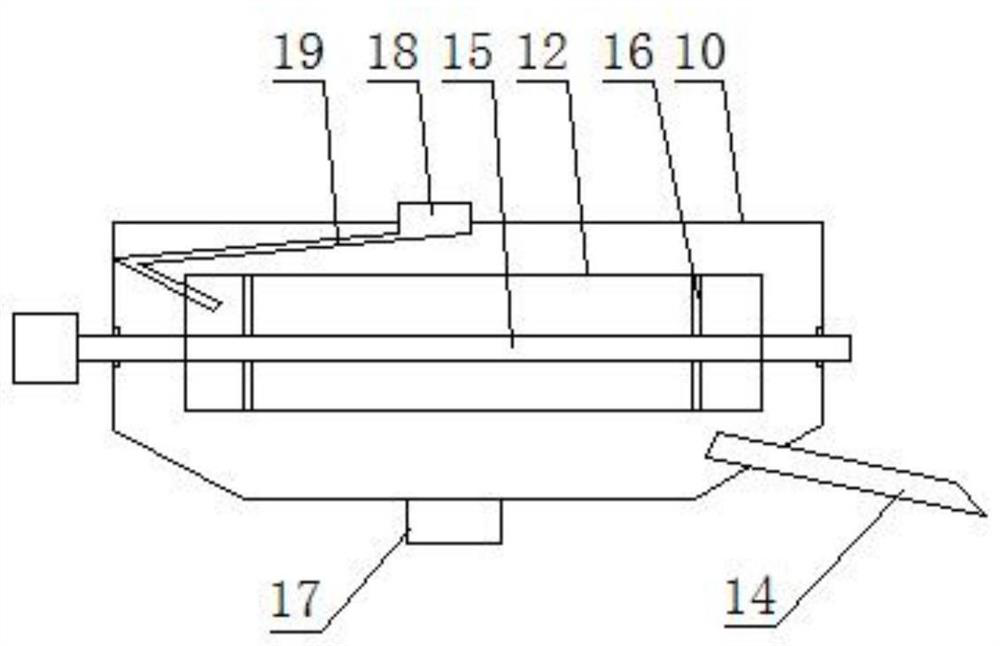

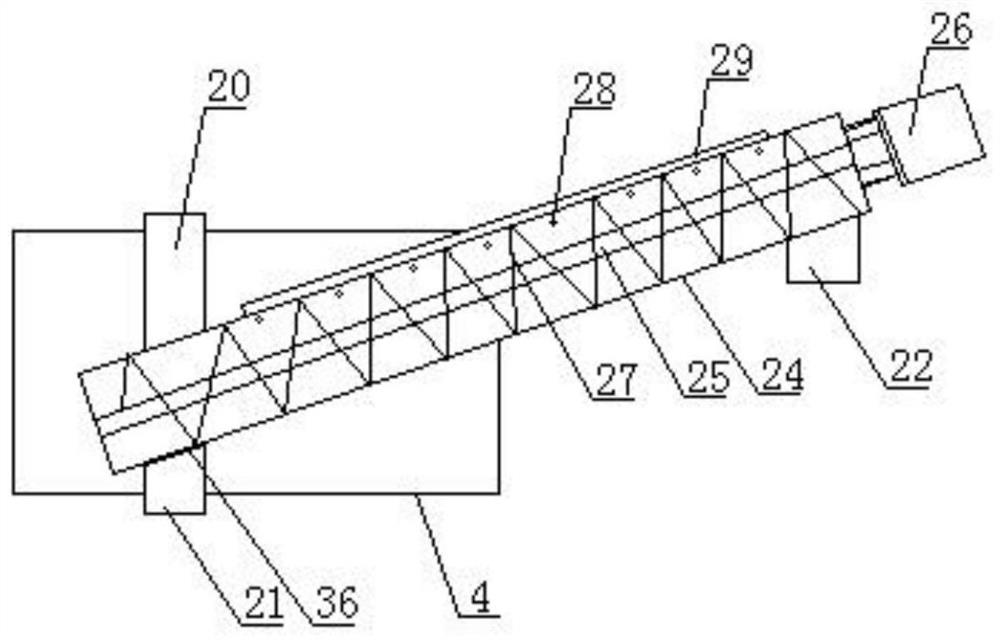

[0057] Place the residual concrete (commercial concrete) recovered from the production site on the feed platform 1 of the separation and recovery device, or the fluid produced by the cleaning tank of the commercial concrete transport vehicle flows directly into the separation and recovery device through the feed platform 1 of the separation and recovery device In the aggregate separation screen 2, the residual concrete aggregate is separated and recovered. The separation and recovery device is composed of a feeding platform 1, an aggregate separating screen 2, a separating auger 3, an assembly box 4, a sedimentation tank 5, a collection tank 6, a filter press 7 and a liquid storage tank 8. One side of the feeding platform 1 A settling tank 5 is set, and an aggregate collection tank 9 is set between the settling tank 5 and the f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com