Carrying device for impeller and carrying method of carrying device

A technology for handling devices and impellers, which is applied in the direction of lifting devices, lifting frames, springs/shock absorbers, etc., and can solve the problems of large damage to the blade finish, low efficiency, and increased costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] The technical solutions of the present invention will be clearly and completely described below through specific embodiments.

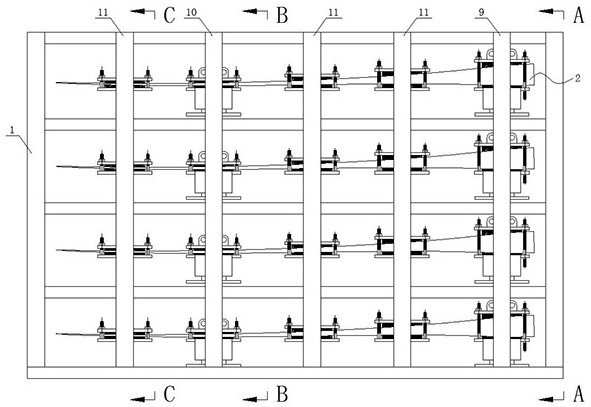

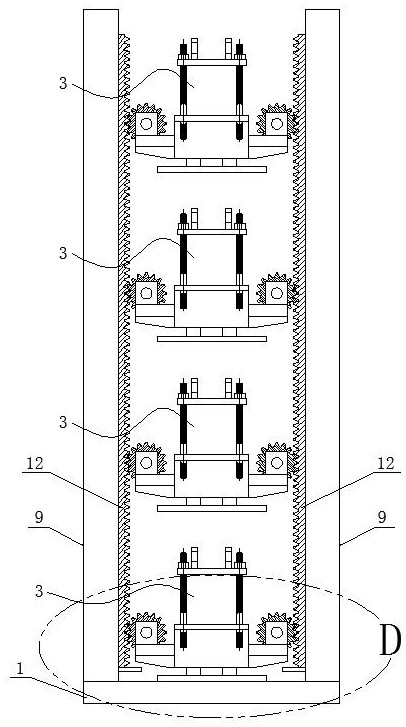

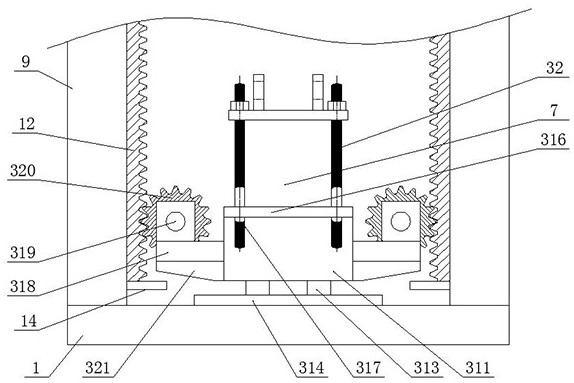

[0048] A transporting device for an impeller of the present invention includes a transporting frame 1, a blade transporting mechanism 2, a first support 9, a second support 10, a third support 11, a first rack 12, a second rack 13 and a lift Device 5; specific structure such as Figure 1~7 As shown, the transport frame 1 is a hollow cuboid frame structure placed horizontally, and four blade transport mechanisms 2 arranged horizontally and horizontally are arranged at intervals in parallel up and down inside it; The front and rear sides are also vertically symmetrically provided with first pillars 9, and the two first pillars 9 are coplanar with the front and rear sides of the transport frame 1 respectively, and integrally formed; The front and rear sides of the power point are also vertically and symmetrically provided with second pillars 10, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com