Liquid cargo tank and liquefied gas ship

A technology for liquefied gas ships and liquid cargo tanks, which is applied to ship accessories, transportation and packaging, and for bulk cargoes. effect of weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

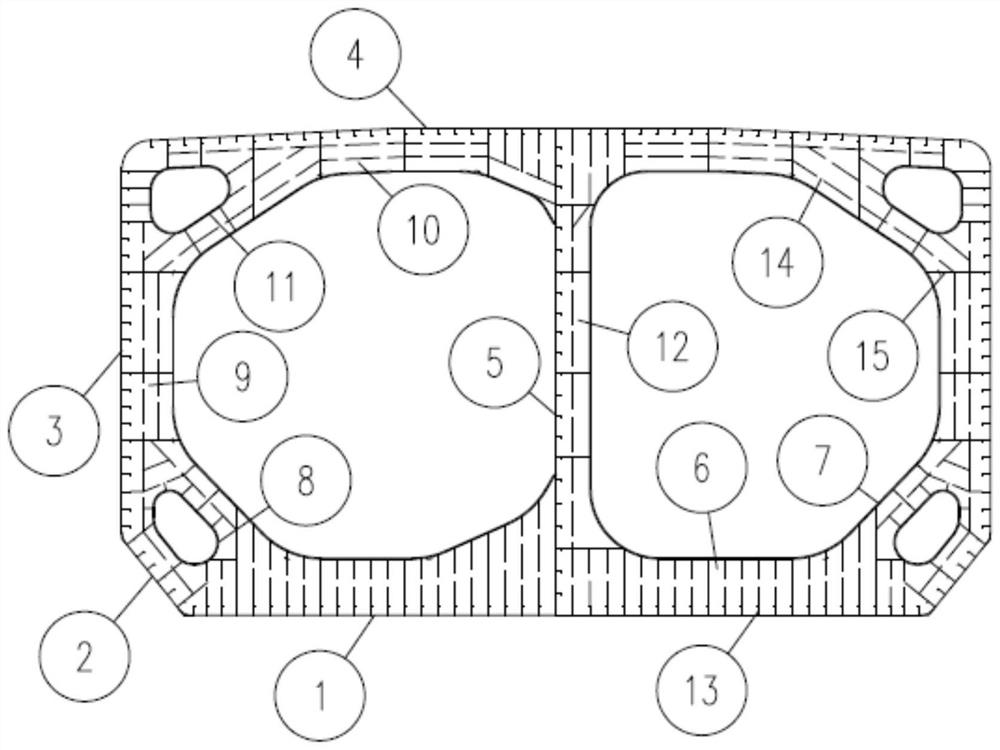

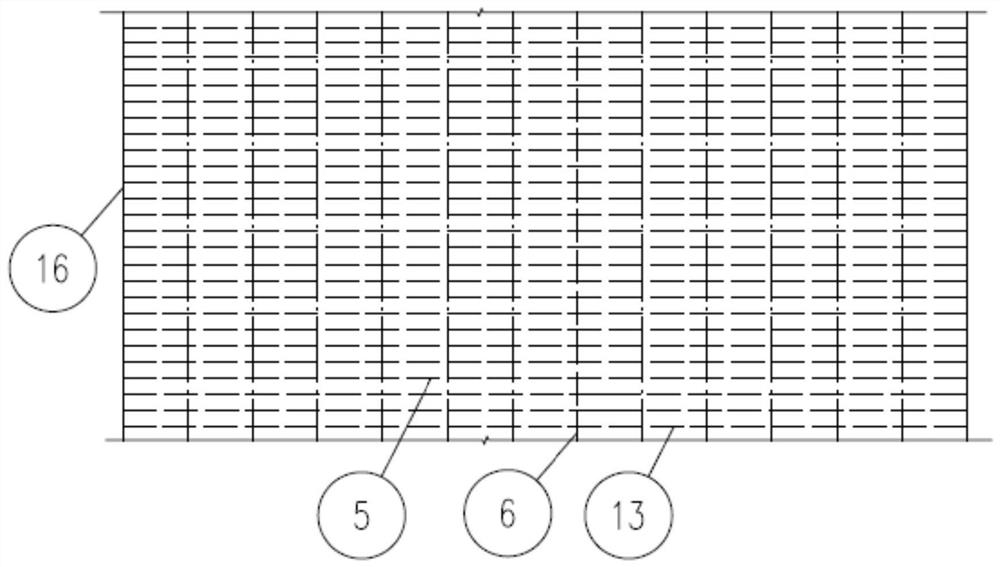

[0033] This embodiment provides a liquid cargo tank, refer to figure 1 , the liquid cargo tank is applied to a liquefied gas carrier, including an outer shell and a supporting structure; specifically, the outer shell includes a bottom wall 1, a side wall 3 and a top wall 4; the supporting structure includes a bottom strong frame 6, a lateral strong frame 9, a top strong frame frame 10 and opening web; the bottom strong frame 6 is connected to the inner side of the bottom wall 1, the lateral strong frame 9 is connected to the inner side of the side wall 3, the top strong frame 10 is connected to the inner side of the top wall 4, the bottom strong frame 6 and the Between the lateral strong frames 9, between the top strong frames 10 and the lateral strong frames 9, all are connected by opening webs.

[0034] In this embodiment, by using the perforated web as the strengthened web structure of the cargo tank, the width of the liquefied hull of the existing Type A liquid cargo tank ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com