A dust-removing FRP hole punching machine that is easy to customize the number of holes and adjust the hole spacing

A glass steel pipe and hole adjustment technology, which is applied in metal processing and other directions, can solve the problems of less equipment functions, the inability to punch different numbers of holes, and the inability to adjust the hole distance, so as to prevent random drifting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

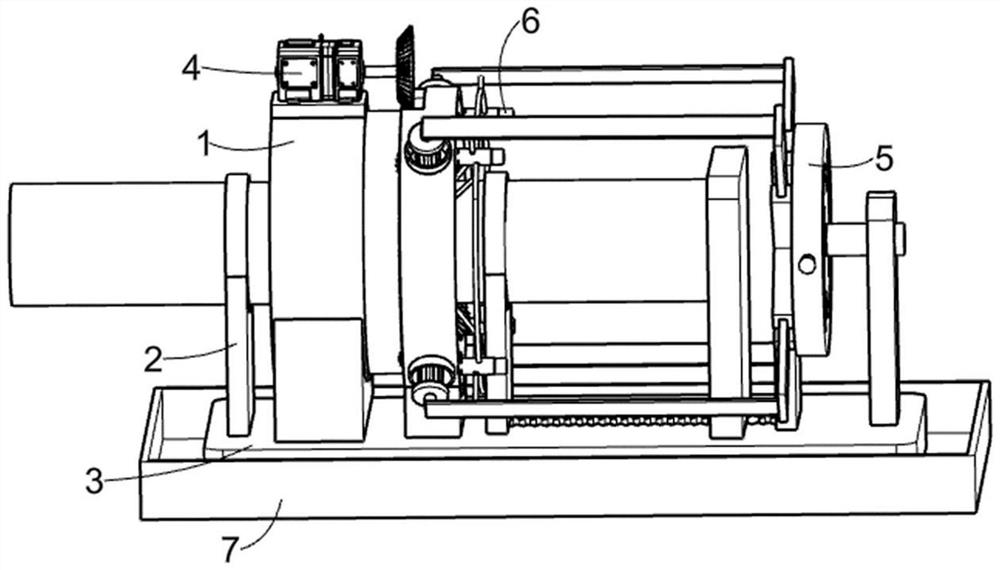

[0021] Example: a dust-removing glass fiber reinforced plastic pipe punching machine that is convenient for customizing the number of holes and adjusting the hole spacing, such as Figure 1-8 As shown, including a first support frame 1, a second support frame 2, a distance precision mechanism 3, a drilling mechanism 4, an electric drill opening and closing mechanism 5 and a water-cooled dust removal mechanism 6, the distance precision mechanism for controlling the spacing of the holes 3 is arranged on the first support frame 1, the two second support frames 2 are arranged on the distance precision mechanism 3, and the two second support frames 2 are used to support the glass steel pipe that needs to be punched. The drilling mechanism 4 for drilling the glass steel pipe is arranged on the first support frame 1 and the distance precision mechanism 3, and the electric drill opening and closing mechanism 5 for auxiliary punching is arranged on the distance precision mechanism 3. A...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com