Method for improving H13 steel rolling, and H13 round steel

A technology for steel grades and rolls, applied in the field of steel grade processing, can solve the problems of difficult pass bite, rolling scrap or return, and rapid cooling of rolled pieces, so as to improve tissue center looseness, reduce rolling scrap or return, and ensure production. The effect of efficiency and production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

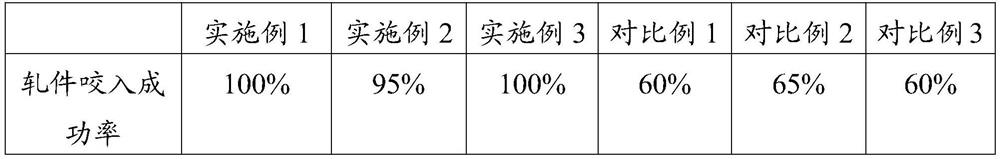

[0055] Example 1, 20 H13 steel billets were put into a continuous furnace for heating, and then rolled, and the heated H13 steel billets were rolled in 11 passes in the blanking machine, wherein, in the first pass In the first rolling, a small reduction process was adopted, and the reduction H1 was 35 mm, and the cooling water of the roll was turned off for rolling; in the second pass, a large reduction process was adopted, and the reduction H2 was 74 mm; In the third rolling pass, the large reduction process is adopted, and the reduction H3 is 79mm. In the fourth to eleventh passes, the roll cooling water is turned on for rolling, and the roll cooling water flow N is 90m 3 / h, the finished product is finally made, and the success rate of biting the rolled piece is recorded, and the biting success rate of the rolled piece is 100%.

Embodiment 2

[0056] Example 2, 20 H13 steel billets were put into a continuous furnace for heating, and then rolled, and the heated H13 steel billets were rolled in 11 passes in the blanking machine, wherein, in the first pass In the first rolling, a small reduction process was adopted, and the reduction H1 was 40 mm, and the cooling water of the roll was turned off for rolling; in the second rolling pass, a large reduction process was adopted, and the reduction H2 was 75 mm; In the third rolling pass, the large reduction process is adopted, and the reduction H3 is 80mm. In the fourth to eleventh passes, the roll cooling water is turned on for rolling, and the roll cooling water flow N is 95m 3 / h, the finished product is finally made, and the success rate of the biting of the rolled piece is recorded, and the biting success rate of the rolled piece is 95%.

Embodiment 3

[0057] Example 3, 20 H13 steel billets were put into a continuous furnace for heating, and then rolled, and the heated H13 steel billets were rolled in 11 passes in the blanking machine, wherein, in the first pass In the first rolling, a small reduction process was adopted, and the reduction H1 was 45 mm, and the cooling water of the roll was turned off for rolling; in the second pass, a large reduction process was adopted, and the reduction H2 was 76 mm; In the third rolling pass, the large reduction process is adopted, and the reduction H3 is 81mm. In the fourth to eleventh passes, the roll cooling water is turned on for rolling, and the roll cooling water flow N is 100m 3 / h, the finished product is finally made, and the success rate of biting the rolled piece is recorded, and the biting success rate of the rolled piece is 100%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com