Kitchen garbage disposer

A technology of kitchen waste and processor, which is applied in gas treatment, grain treatment, chemical instruments and methods, etc., can solve the problems of poor crushing function, odor, and inability to fully pulverize kitchen waste, so as to avoid the overflow of odor , convenient water evaporation, simple and reasonable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the drawings in the embodiments of the present invention.

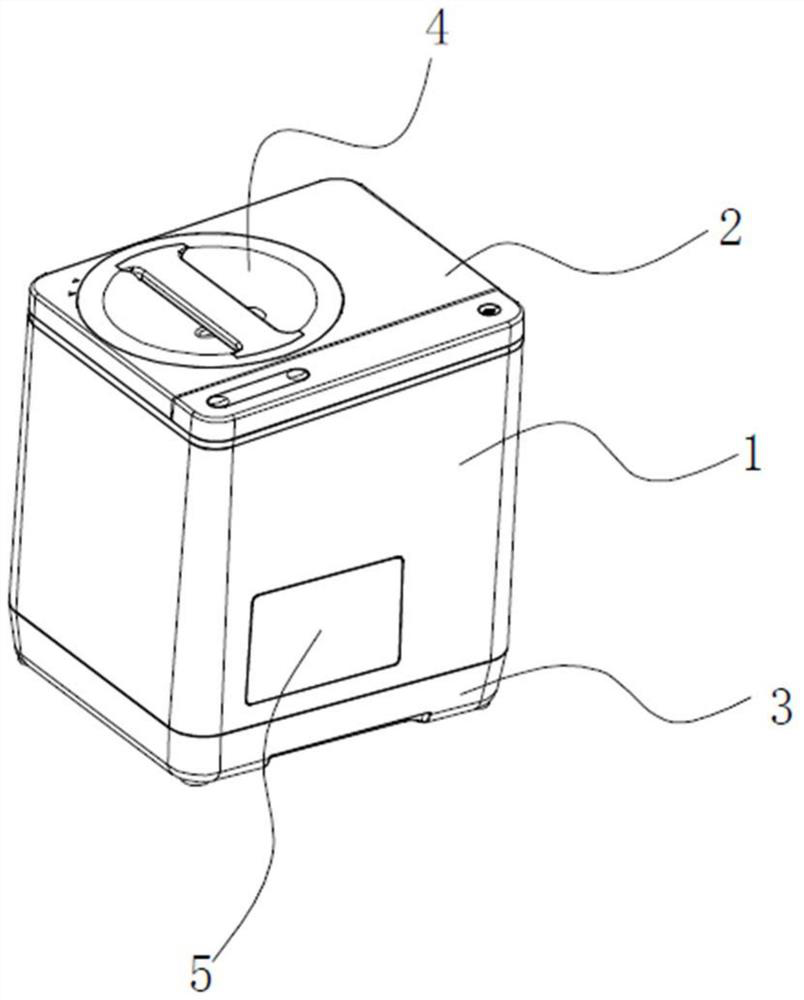

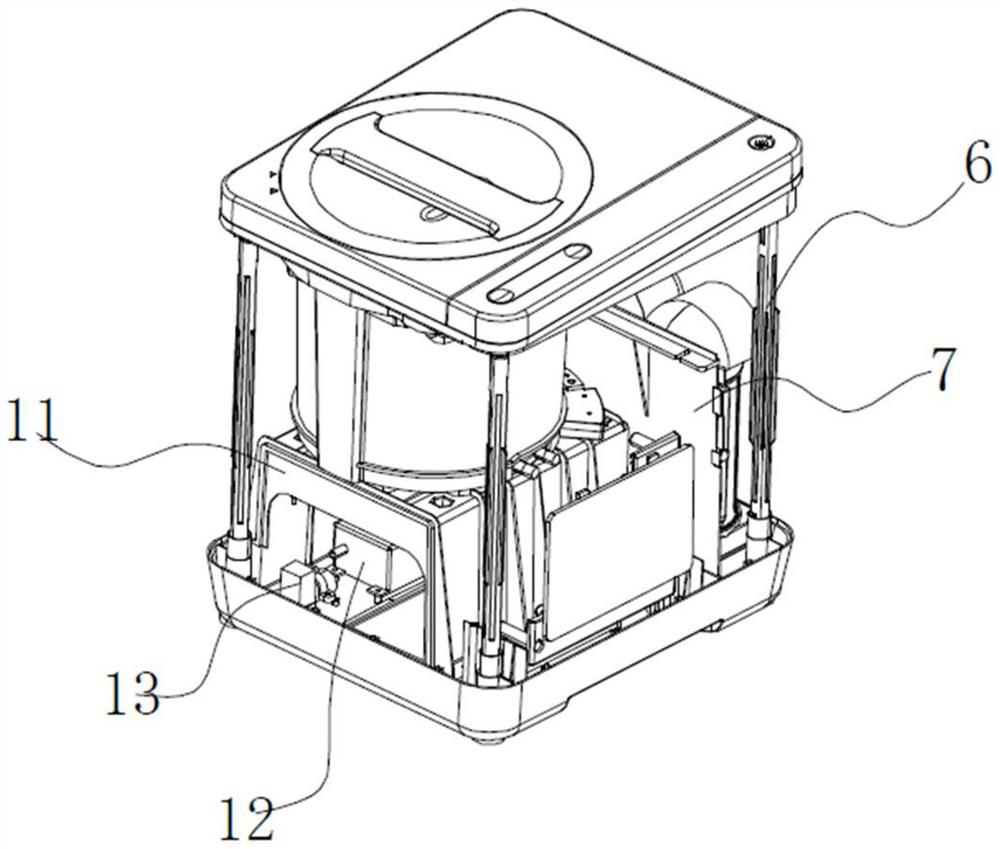

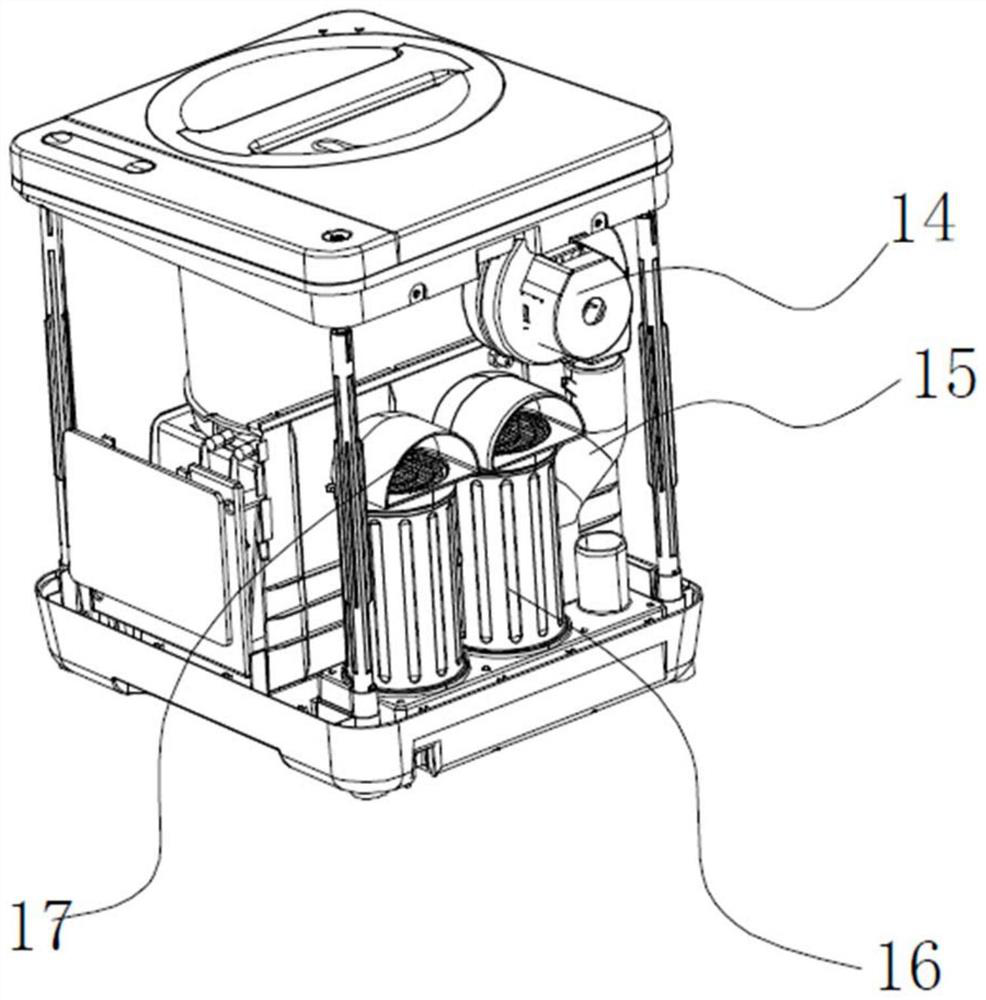

[0025] Such as Figure 1-7 As shown, the present invention provides a kitchen waste disposer, which includes a casing 1, an upper cover 2 and a base 3, a storage bucket 10 is arranged inside the casing 1, and a heating plate 19 is installed at the bottom of the storage bucket 10. The inner bottom of the storage bucket 10 is rotatably equipped with a stirring blade 9, the stirring blade 9 is driven to rotate by the drive assembly 20 below the storage bucket 10, and a water tank 21 is installed on one side of the storage bucket 10, so The water tank 21 is connected to the exhaust fan 14 through the pipeline 15, the air inlet 18 of the exhaust fan 14 is located on the upper side of the storage barrel 10, and the upper cover 2 is equipped with a detachable barrel cover correspondi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com