Dust removal device for aluminum alloy door and window production

A technology for aluminum alloy doors and windows and a dust removal device, which is applied in the directions of dry gas arrangement, cleaning methods and utensils, and cleaning methods using tools, etc., can solve problems such as low efficiency, insufficient dust removal effect, and affecting the appearance of aluminum alloy doors and windows.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] In order to deepen the understanding of the present invention, the present invention will be further described below in conjunction with the examples, which are only used to explain the present invention, and do not constitute a limitation to the protection scope of the present invention.

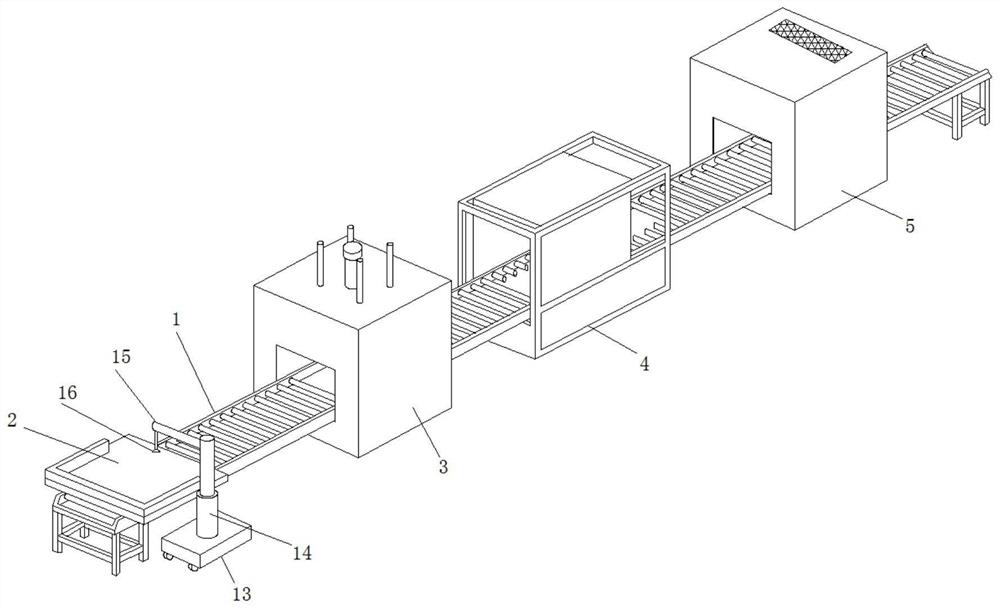

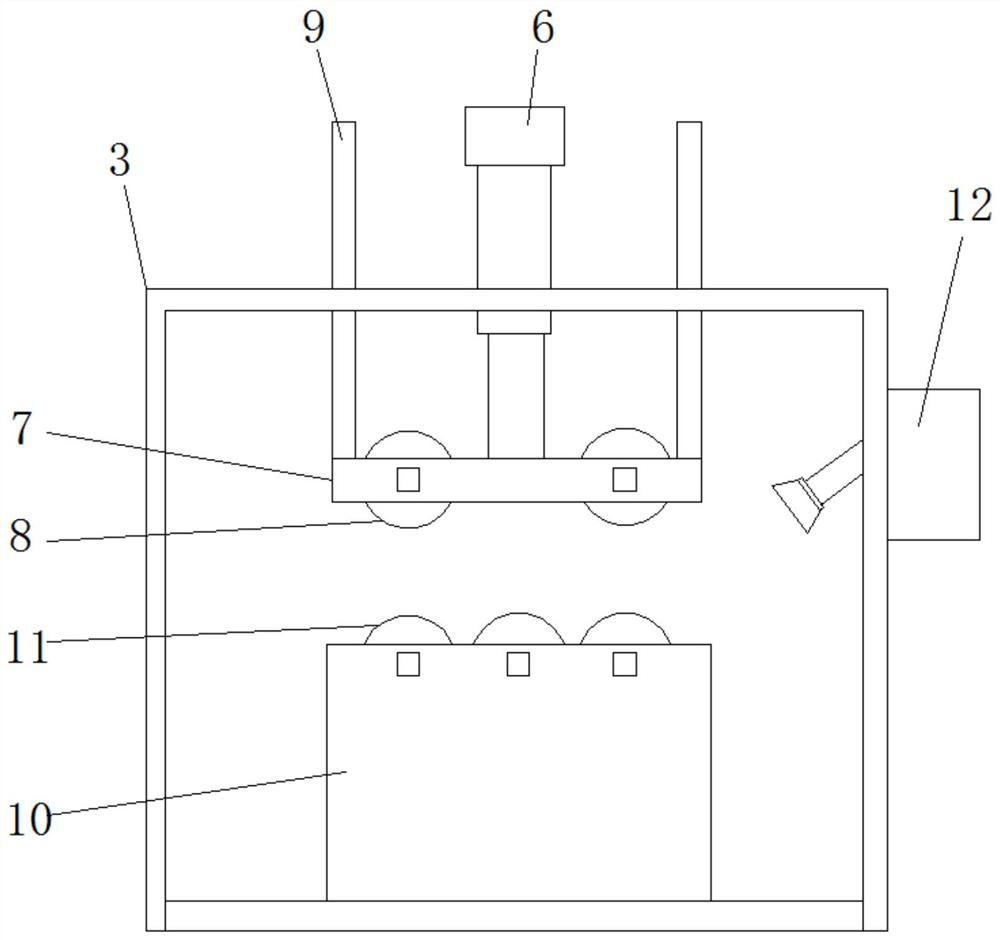

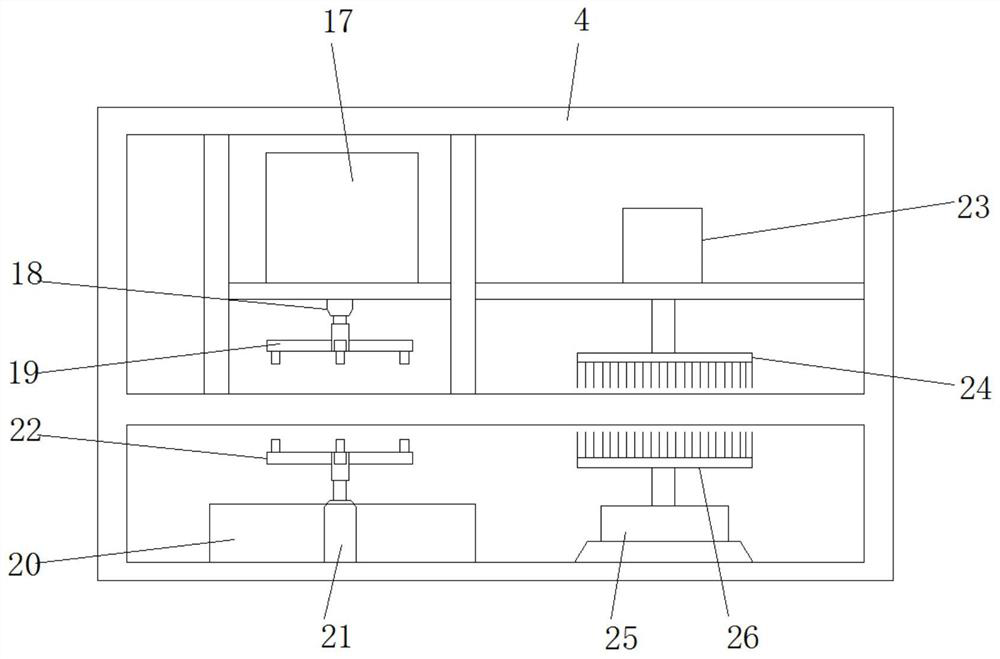

[0020] according to figure 1 , 2 , 3, 4, and 5, the present embodiment provides a dust removal device for the production of aluminum alloy doors and windows, including a transmission frame 1, a code tray 2, a feeding assembly, a floating ash treatment bin 3, a stain treatment bin 4 and An air-drying warehouse 5, one end on the transfer frame 1 is provided with a code tray 2, and a side position of the code tray 2 is provided with a feeding assembly, and the transfer frame 1 is sequentially provided with Floating ash treatment bin 3, stain treatment bin 4 and air-drying bin 5, when in use, put the aluminum alloy doors and windows on the stacking tray 2, use the feeding components to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com