Preparation method of flexible Ag-Pd/ZrO2@carbon fiber cloth catalyst

A carbon fiber cloth and catalyst technology, which is used in the preparation of flexible Ag-Pd/ZrO2@carbon fiber cloth catalysts, can solve problems such as poor electrical conductivity, and achieve the effects of strong binding force, easy installation, and large active reaction site area.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

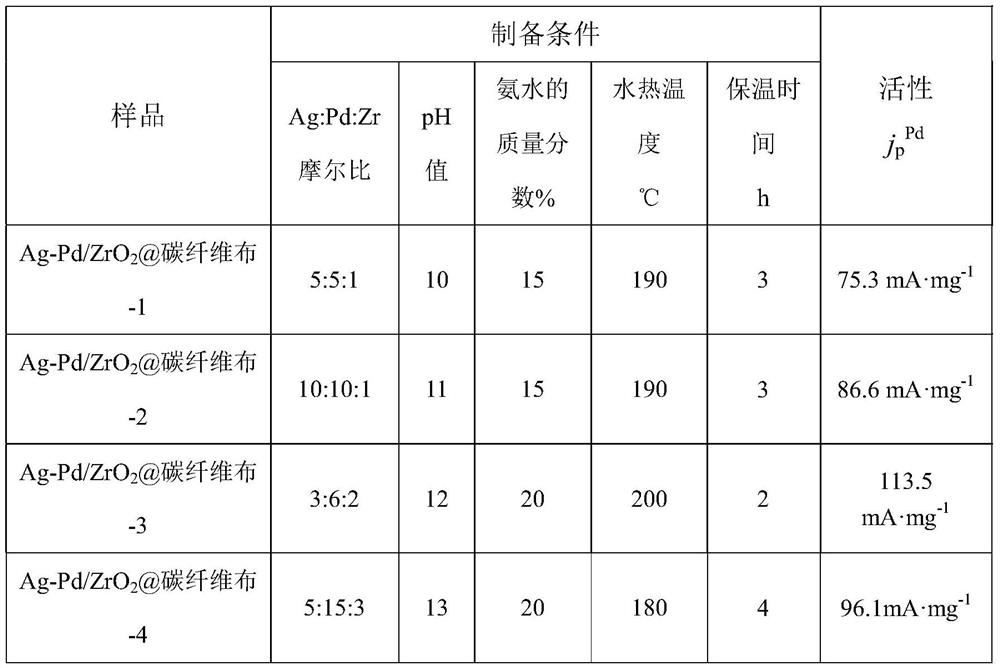

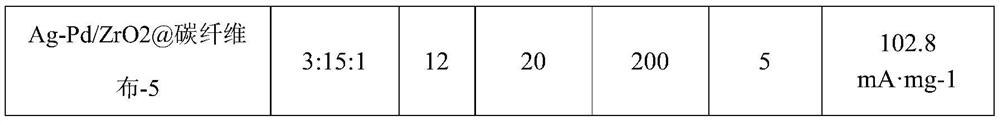

Examples

Embodiment 1

[0027] Flexible Ag-Pd / ZrO of the present invention 2 The preparation method of @carbon fiber cloth catalyst is implemented according to the following steps:

[0028] Step 1. Dissolve carbon fiber cloth in acetone solution, ultrasonically clean it to remove surface oil, then use deionized water and alcohol to perform ultrasonic cleaning in turn, dry naturally, and set aside;

[0029] Among them, the time of each ultrasonic cleaning is 30min;

[0030] Step 2, arrange the carbon fibers obtained after step 1 in ZrOCl containing a certain molar ratio 2 ·8H 2 O, PdCl 2 and AgCl 2 In the mixed solution, ammonia water is then added dropwise to the mixed solution until the pH of the mixed solution is 10, and the precursor is obtained by ultrasonication at room temperature for a period of time;

[0031] Among them, PdCl 2 and AgCl 2 The molar ratio of PdCl is 1:1; 2 and ZrOCl 2 ·8H 2 The molar ratio of O is 5:1; the loading of Pd is 1wt%; the loading of Ag is 1wt%; the ultraso...

Embodiment 2

[0035] Flexible Ag-Pd / ZrO of the present invention 2 The preparation method of @carbon fiber cloth catalyst is implemented according to the following steps:

[0036] Step 1. Dissolve carbon fiber cloth in acetone solution, ultrasonically clean it to remove surface oil, then use deionized water and alcohol to perform ultrasonic cleaning in turn, dry naturally, and set aside;

[0037] Among them, the time of each ultrasonic cleaning is 30min;

[0038] Step 2, arrange the carbon fibers obtained after step 1 in ZrOCl containing a certain molar ratio 2 ·8H 2 O, PdCl 2 and AgCl 2 In the mixed solution, ammonia water is added dropwise to the mixed solution until the pH of the mixed solution is 11, and the precursor is obtained by ultrasonication at room temperature for a period of time;

[0039] Among them, PdCl 2 and AgCl 2 The molar ratio of PdCl is 1:1; 2 and ZrOCl 2 ·8H 2 The molar ratio of O is 10:1; the loading of Pd is 1.5wt%; the loading of Ag is 1.5wt%; the ultraso...

Embodiment 3

[0043] Flexible Ag-Pd / ZrO of the present invention 2 The preparation method of @carbon fiber cloth catalyst is implemented according to the following steps:

[0044] Step 1. Dissolve carbon fiber cloth in acetone solution, ultrasonically clean it to remove surface oil, then use deionized water and alcohol to perform ultrasonic cleaning in turn, dry naturally, and set aside;

[0045] Among them, the time of each ultrasonic cleaning is 30min;

[0046] Step 2, arrange the carbon fibers obtained after step 1 in ZrOCl containing a certain molar ratio 2 ·8H 2 O, PdCl 2 and AgCl 2 In the mixed solution, ammonia water is added dropwise to the mixed solution until the pH of the mixed solution is 12, and the precursor is obtained by ultrasonication at room temperature for a period of time;

[0047] Among them, PdCl 2 and AgCl 2 The molar ratio of PdCl is 2:1; 2 and ZrOCl 2 ·8H 2 The molar ratio of O is 3:1; the loading of Pd is 2wt%; the loading of Ag is 1wt%; the ultrasonic t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com