Servo valve unit and machine

A servo valve, unit main body technology, applied in servo motors, servo meter circuits, servo motor components, etc., can solve problems such as reducing and unavoidable compressibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

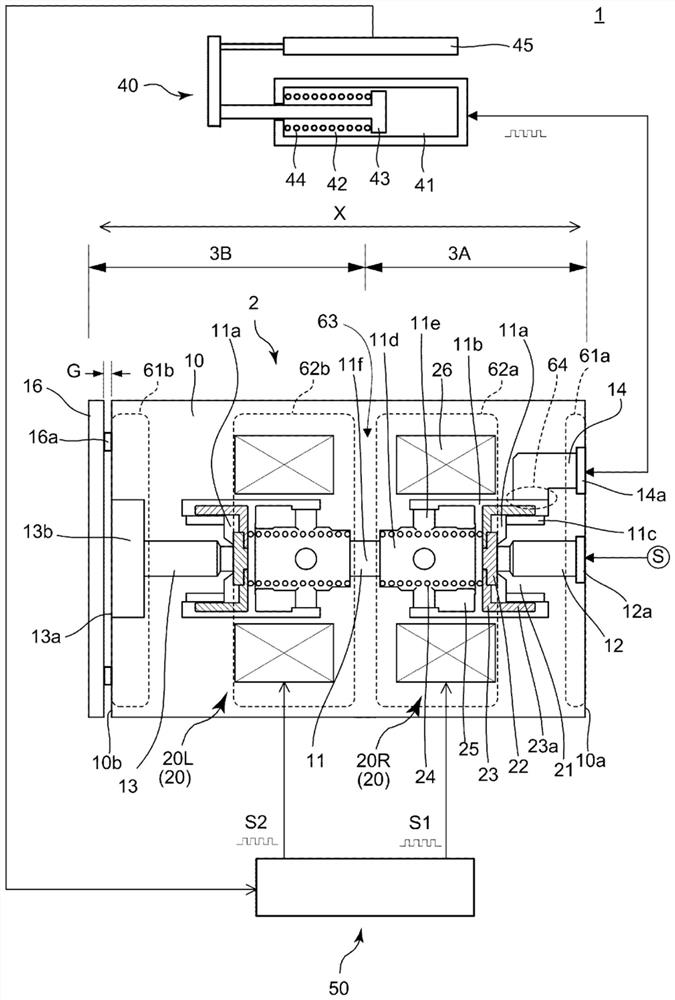

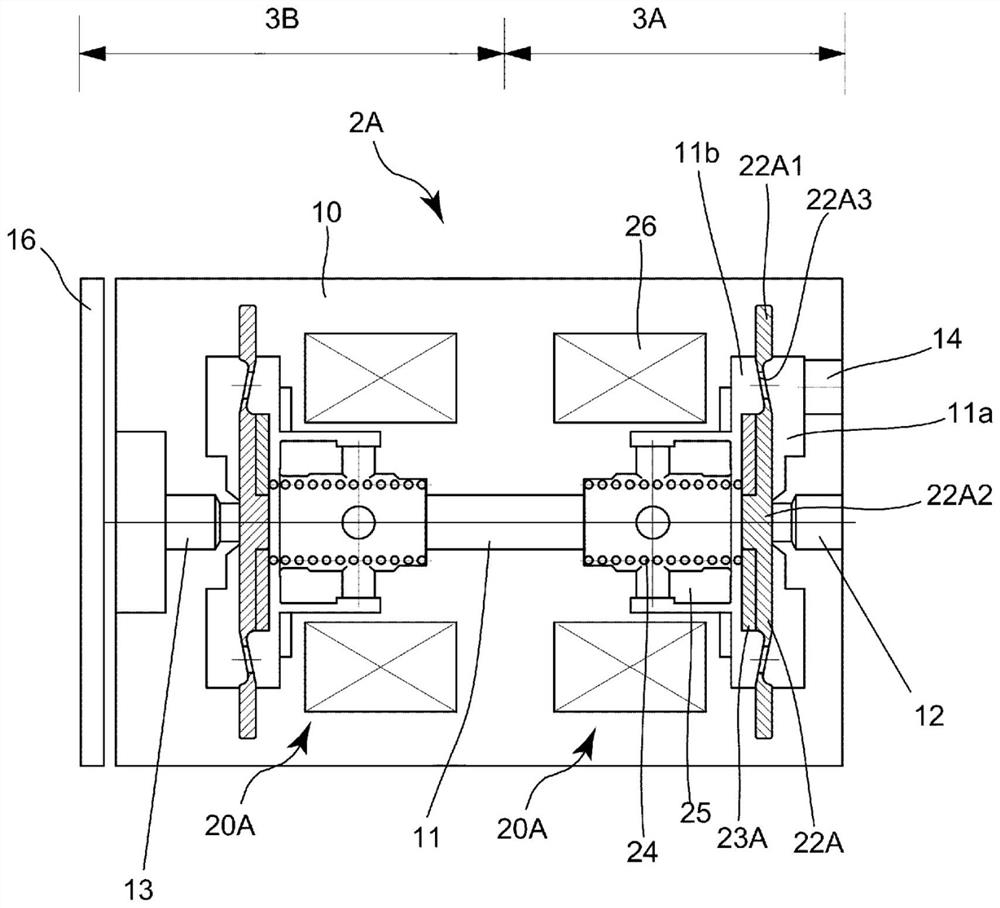

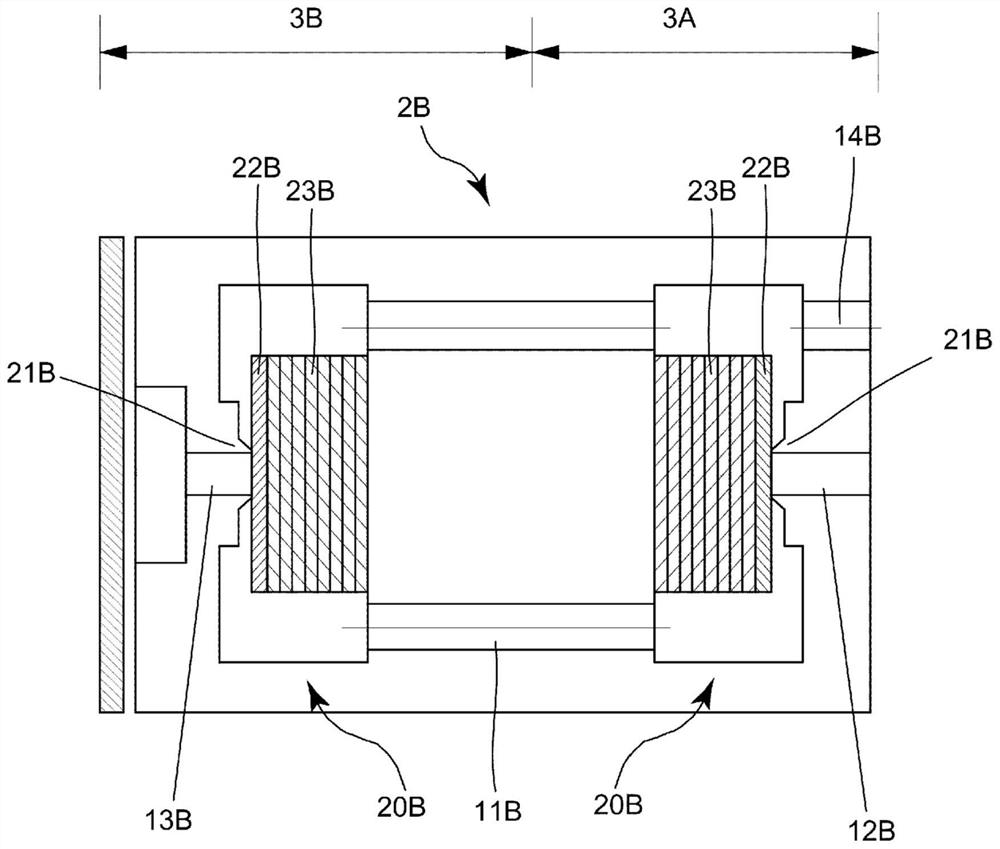

[0050] figure 1 A servo valve unit 2 and an air pressure control device 1 using the servo valve unit 2 according to one embodiment of the present invention are shown. The pneumatic control device 1 has a servo valve unit 2 , a pneumatic cylinder 40 and a controller 50 . The servo valve unit 2 has a valve body 10 formed with hollow spaces such as a common flow path 11 , a supply flow path 12 , an exhaust flow path 13 , and a drive flow path 14 . The unit main body 10 may be an assembly of a plurality of parts made of metal or plastic.

[0051] One end of the supply flow path 12 is connected to the common flow path 11 via a first valve portion 20R capable of pulse-like opening and closing based on the first electric pulse S1 . The other end of the supply channel 12 may have a connection portion (joint, etc.) 12a for connecting to a high-pressure air source such as a compressor for supplying high-pressure air S, an air tank, or the like. The connecting portion 12a may be form...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com