Silicon oxide-lithium composite material and preparation method and application thereof

A silicon oxide and lithium sheet technology, applied in nanotechnology, electrochemical generators, active material electrodes, etc. for materials and surface science, can solve problems such as high cost, difficult structure control, complex synthesis process, etc., to achieve guaranteed The effects of stability, increased diffusion rate, and simple manufacturing process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

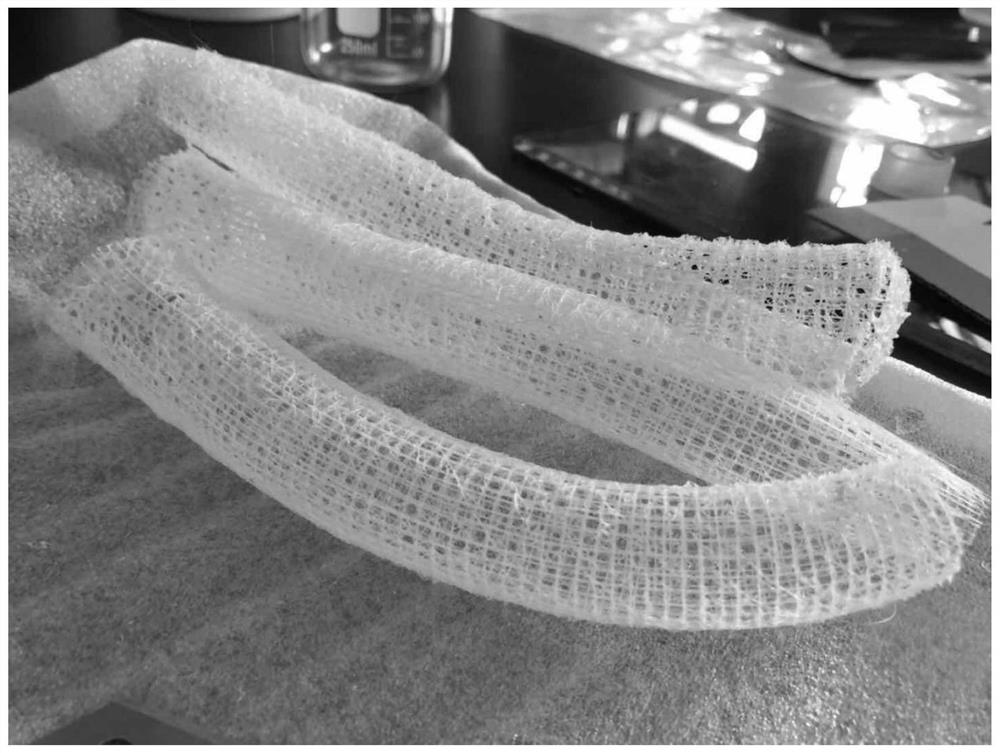

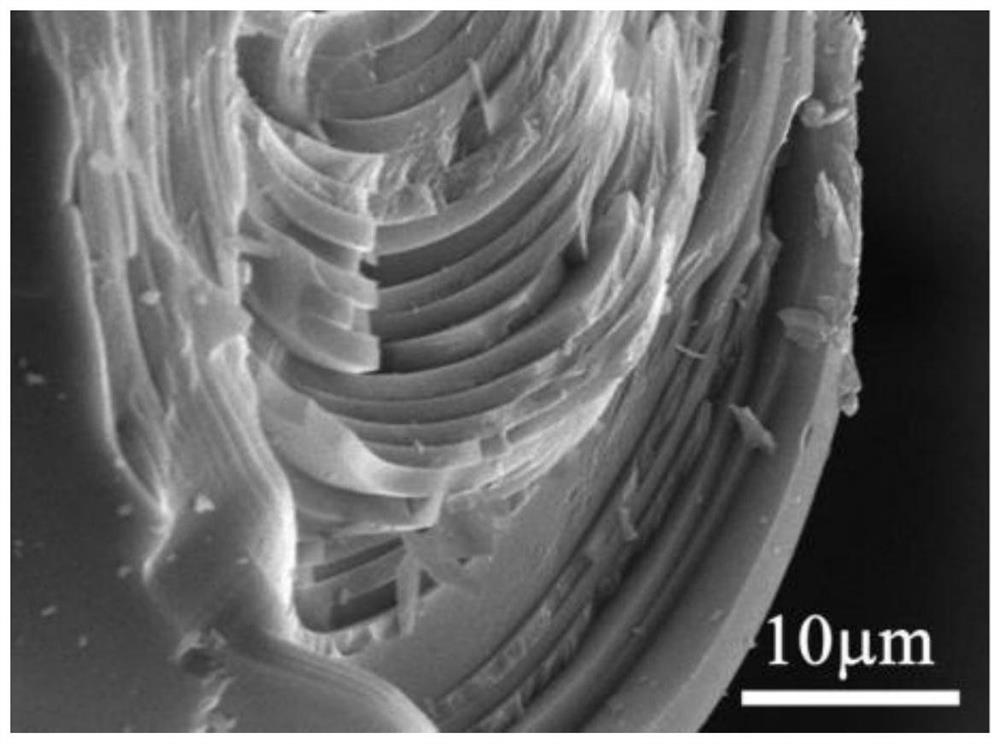

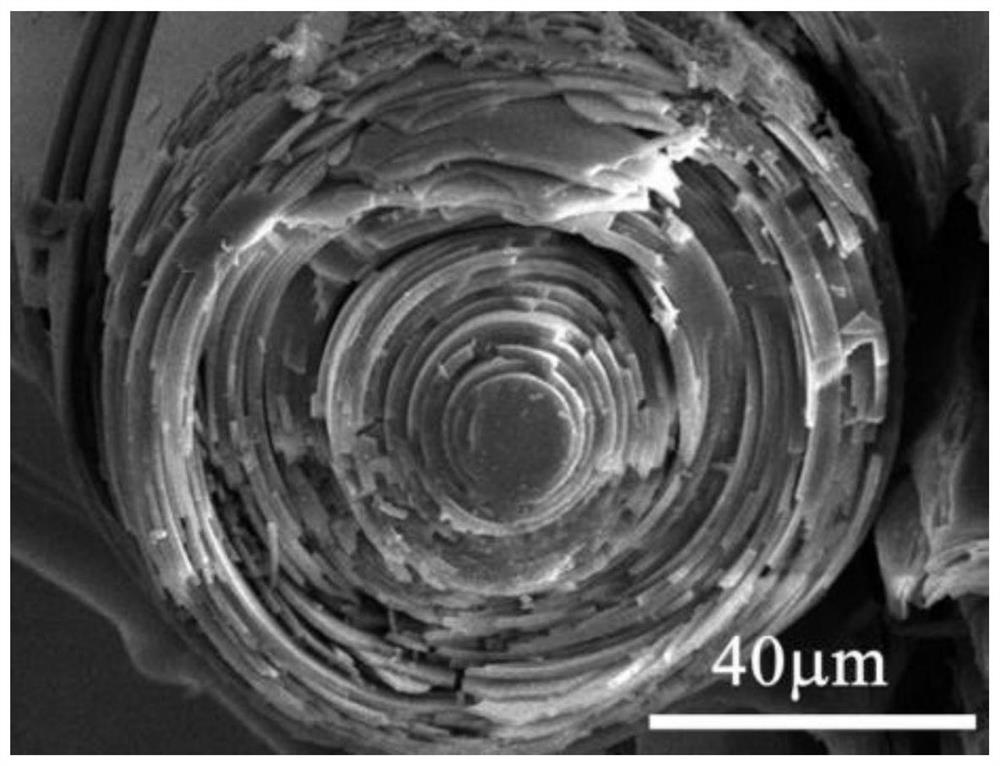

[0039] The "Bringing the Old and the Same Cave" fossil (purchased from the sea shell handicraft wholesale market in the world, the real thing is as follows: figure 1Shown) remove the head and tail, cut into a single-layer sheet structure, the obtained silicon oxide (SiO 2 ) frame sample was washed in distilled water, and the quantitative alcohol was cleaned in an ultrasonic cleaning machine for 20-30 minutes and repeated 3 times, and then dried in a 70°C oven for 24 hours to obtain a silicon oxide frame sample, and its SEM cross-sectional view was as follows: Figure 2-1 and 2-2 shown.

[0040] Cut the silicon oxide frame samples into 2cm*2cm samples respectively, and put them in the glove box (H 2 O2 2 -Li composite pole pieces are punched into a circle in a drying room with a tablet press with a head diameter of 1.2 cm, and silicon oxide-lithium (SiO2) for lithium metal batteries can be obtained. 2 -Li) composite negative electrode, its XDR map and SEM plan view are shown...

Embodiment 2

[0050] The "Bringing the Old and the Same Cave" fossil (purchased from the sea shell handicraft wholesale market in the world, the real thing is as follows: figure 1 Shown) remove the head and tail, cut into a single-layer sheet structure, the obtained silicon oxide (SiO 2 ) frame samples were washed in distilled water, washed with quantitative alcohol in an ultrasonic cleaner for 20-30 minutes and repeated 3 times, and then dried in an oven at 60°C for 24 hours to obtain a silicon oxide frame sample.

[0051] Cut the silicon oxide frame samples into samples with a size of 1.2cm*1.2cm, and put them in the glove box (H 2 O2 2 -Li composite pole pieces are cut into 1.2cm*1.2cm square samples with a blade to obtain silicon oxide-lithium (SiO 2 -Li) composite negative electrode. The resulting silicon oxide-lithium (SiO 2 -Li) composite anodes assembled into lithium metal batteries, including Li / Li half-cells and Li / LiFePO 4 The full battery was tested for cycle stability and c...

Embodiment 3

[0058] The "Bringing the Old and the Same Cave" fossil (purchased from the sea shell handicraft wholesale market in the world, the real thing is as follows: figure 1 Shown) remove the head and tail, cut into a single-layer sheet structure, the obtained silicon oxide (SiO 2 ) frame samples were washed in distilled water, washed with quantitative alcohol in an ultrasonic cleaner for 20-30 minutes and repeated 3 times, and then dried in an oven at 80°C for 24 hours to obtain a silicon oxide frame sample.

[0059] Cut the silicon oxide frame samples into 1cm*1.5cm samples respectively, and put them in the glove box (H 2 O2 2 -Li composite pole pieces are cut into 1cm*1.5cm rectangular samples with a blade to obtain silicon oxide-lithium (SiO 2 -Li) composite negative electrode. The resulting silicon oxide-lithium (SiO 2 -Li) composite anodes assembled into lithium metal batteries, including Li / Li half-cells and Li / LiFePO 4 The full battery was tested for cycle stability and ca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com