Openable and closable oil filtering barrier and range hood with same

A technology for range hoods and range hoods, which is applied to the removal of oil fumes, heating methods, household appliances, etc. It can solve the problems of reduced oil filtering effect, energy saving and environmental protection, and low proportion of oil fume, so as to improve the oil filtering effect and delay the temperature rise. Speed, the effect of reducing fan power

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

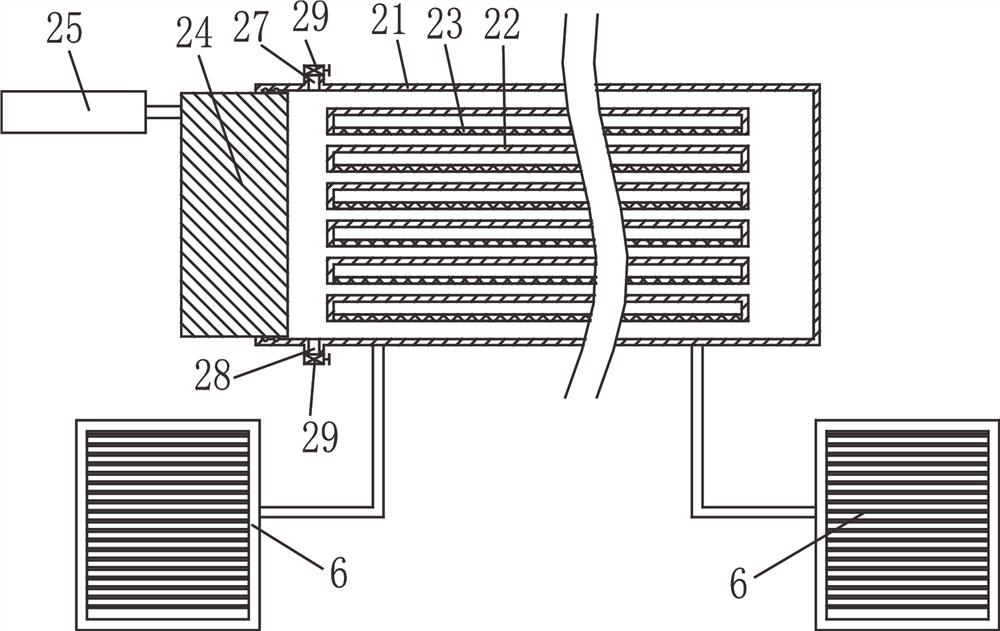

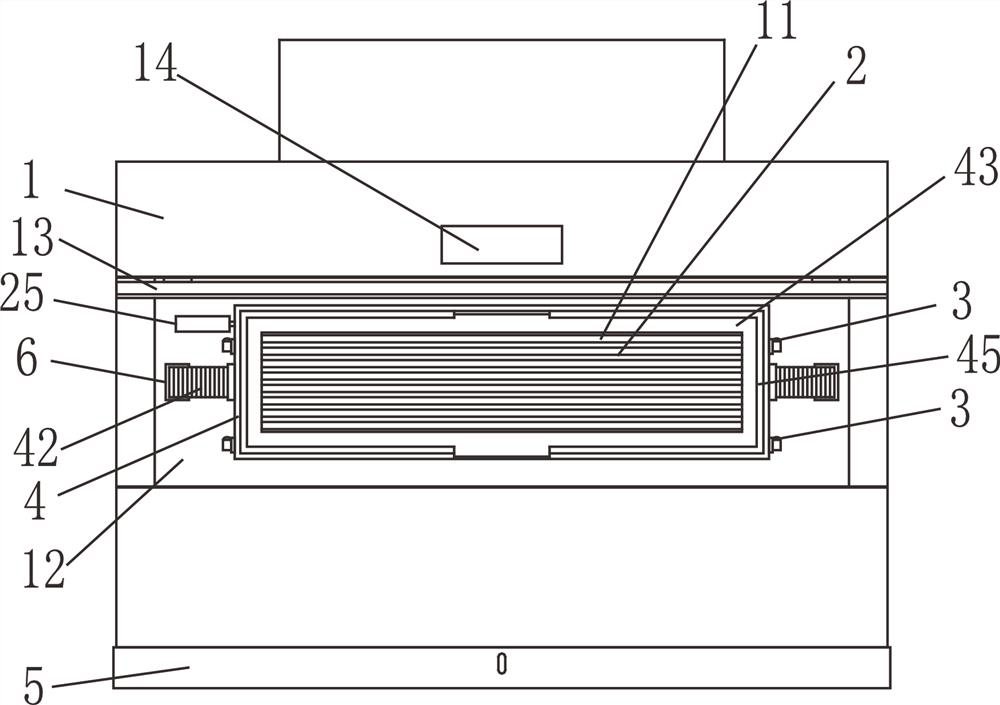

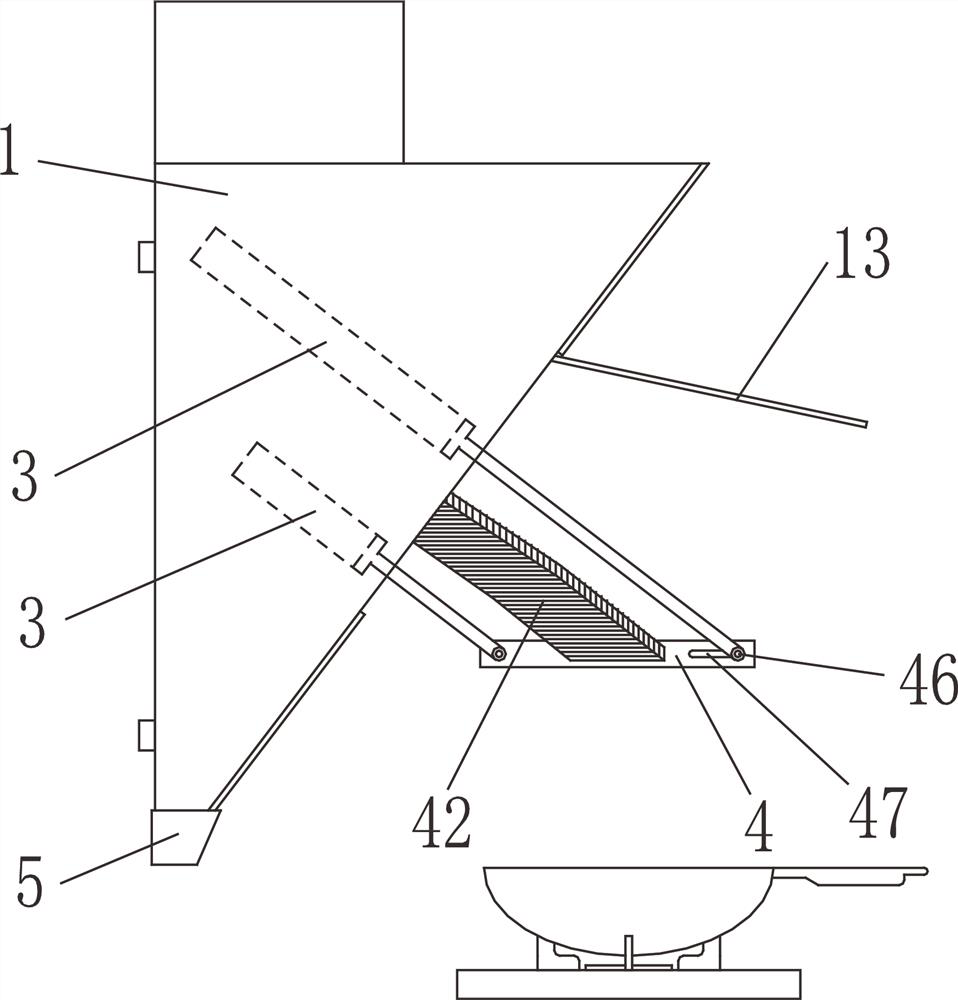

[0021] The present invention will be described in further detail below in conjunction with accompanying drawing and specific embodiment: see Figure 1 to Figure 5 , an openable and closable oil filtering barrier, comprising a frame 21 and a parallel oil filtering barrier 22 inside the frame 21, the frame 21 communicates with the oil filtering barrier 22 in hollow, and the frame 21 and the oil filtering barrier 22 are arranged There is cooling water, at least one side of the oil filter fence 22 is open and an elastic rubber sheet 23 is arranged on the opening, and a movable plug 24 is arranged on the frame 21, and the movable plug 24 is connected with a first electric push rod 25, and the first electric push rod 25 stretches out to stretch out the elastic rubber sheet 23 to block the gap between the oil filter fences 22, and the first electric push rod 25 retracts to reset the elastic rubber sheet 23 to generate oil suction smoke between the oil filter fences 22 gap. Since thi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com