Three-cylinder barrel plating machine

An organic and rack-based technology, applied in the direction of coating, electrolysis process, electrolysis components, etc., can solve the problem of insufficient electroplating in the electroplating pool, etc., and achieve the effect of convenient electroplating and high efficiency electroplating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] Below, the present invention will be further described in conjunction with the accompanying drawings and specific implementation methods. It should be noted that, under the premise of not conflicting, the various embodiments described below or the technical features can be combined arbitrarily to form new embodiments. .

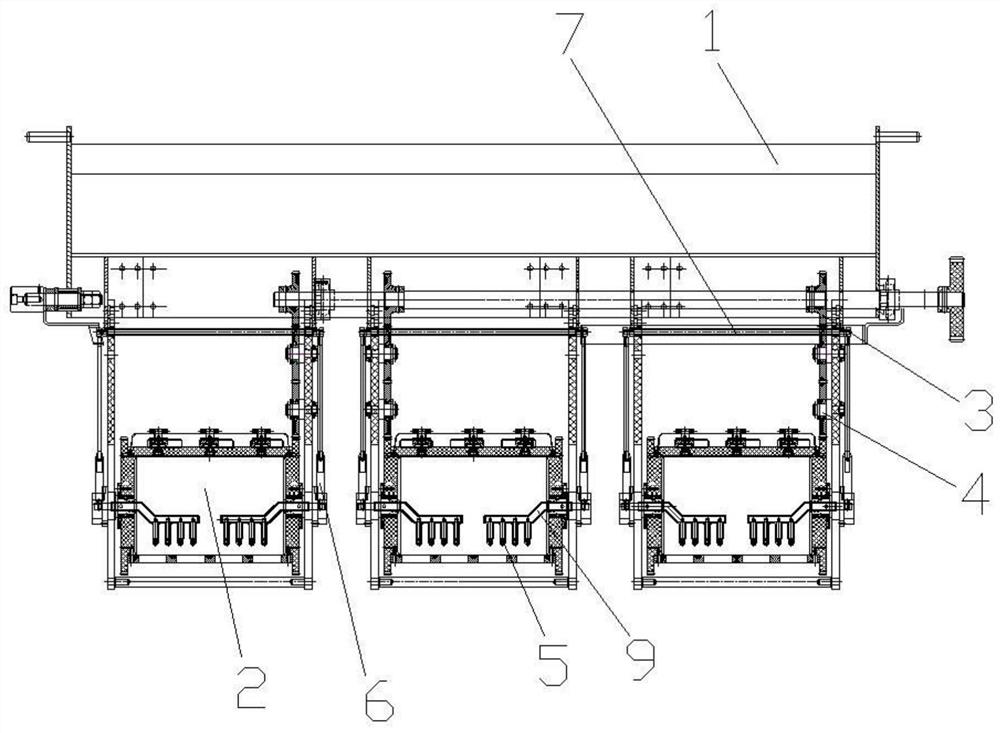

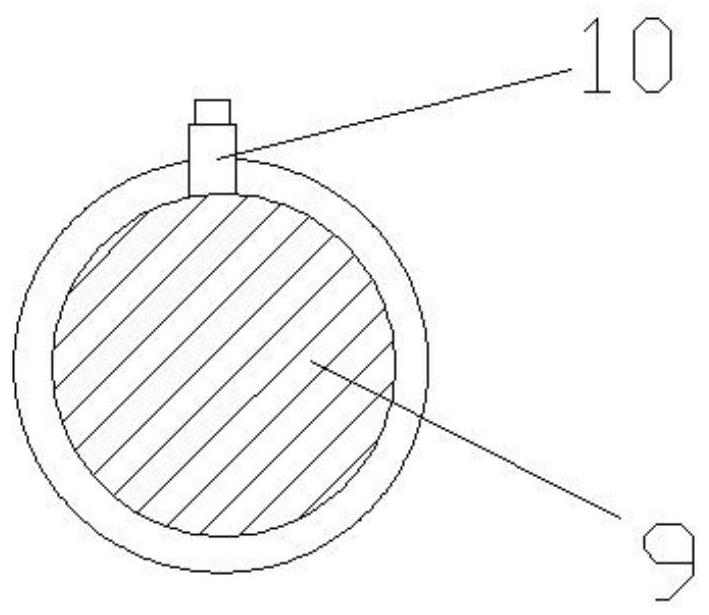

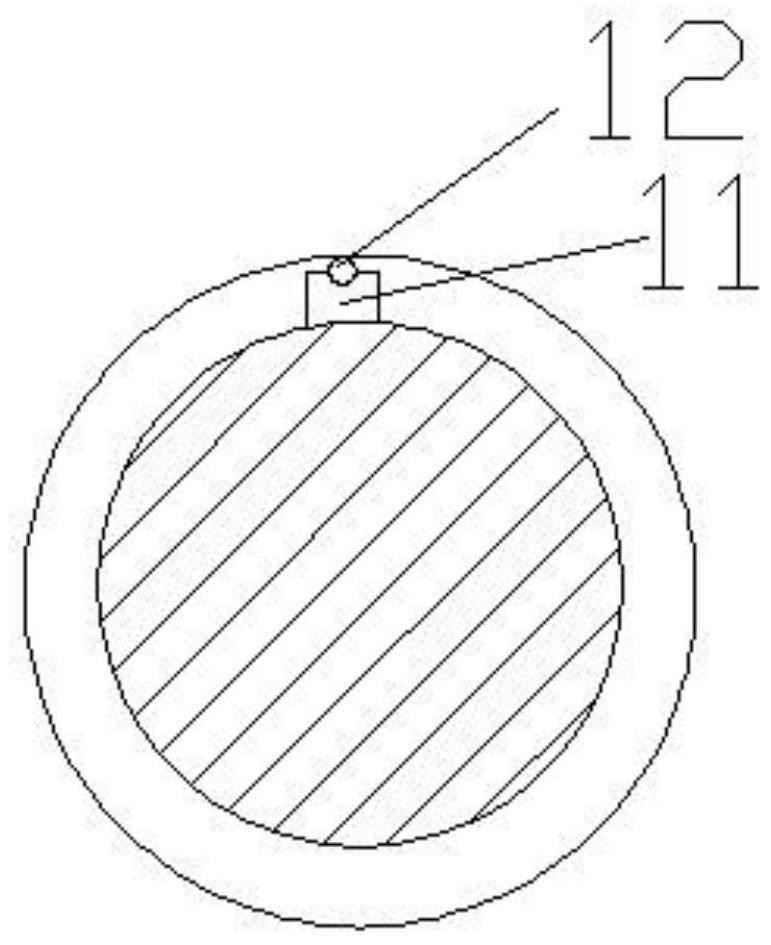

[0015] The three-barrel barrel plating machine is provided with a frame 1, and an electroplating part 2 is arranged on the frame 1, and a gear set is arranged beside the electroplating part 2, and the gear set is a driving gear 3 and a bridge gear set 4. The bridge gear set 4 and the driving gear 3 mesh with each other and drive the electroplating parts to move under the drive of the bridge gear set 4. The electroplating part 2 is an electroplating drum, and an electroplating part 3 is arranged in the electroplating drum, and the electroplating part 3 is an electroplating drum. The electroplating rod 9 is provided with multiple groups of inner cathode ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com