A flame-retardant polyurethane foam with electromagnetic shielding function and preparation method thereof

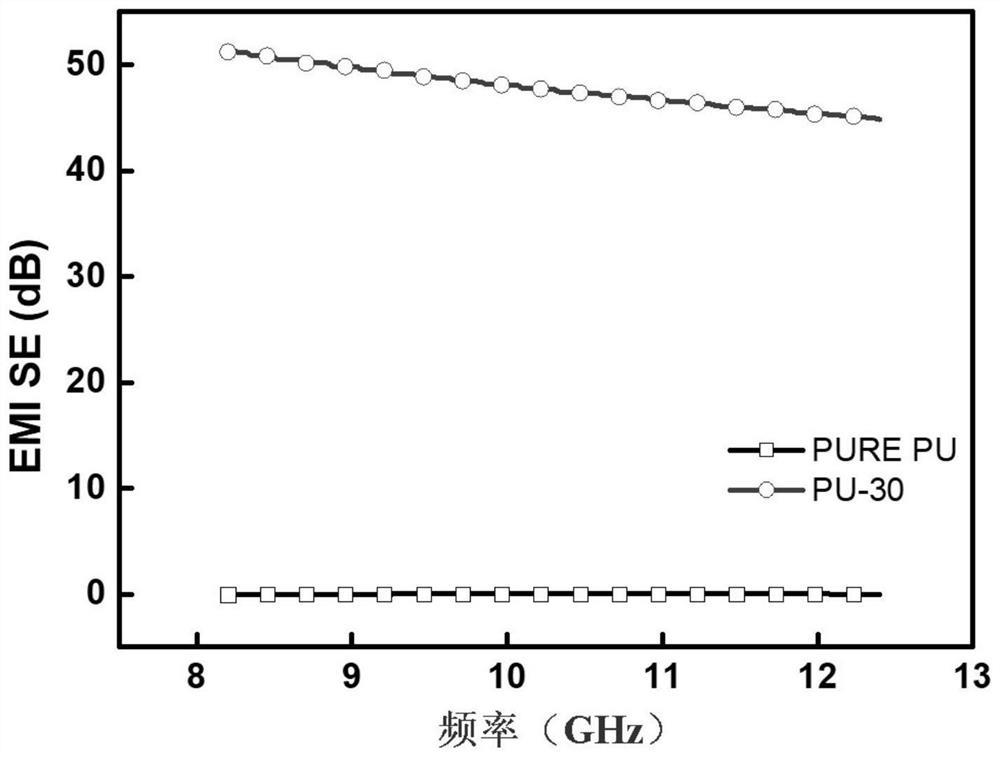

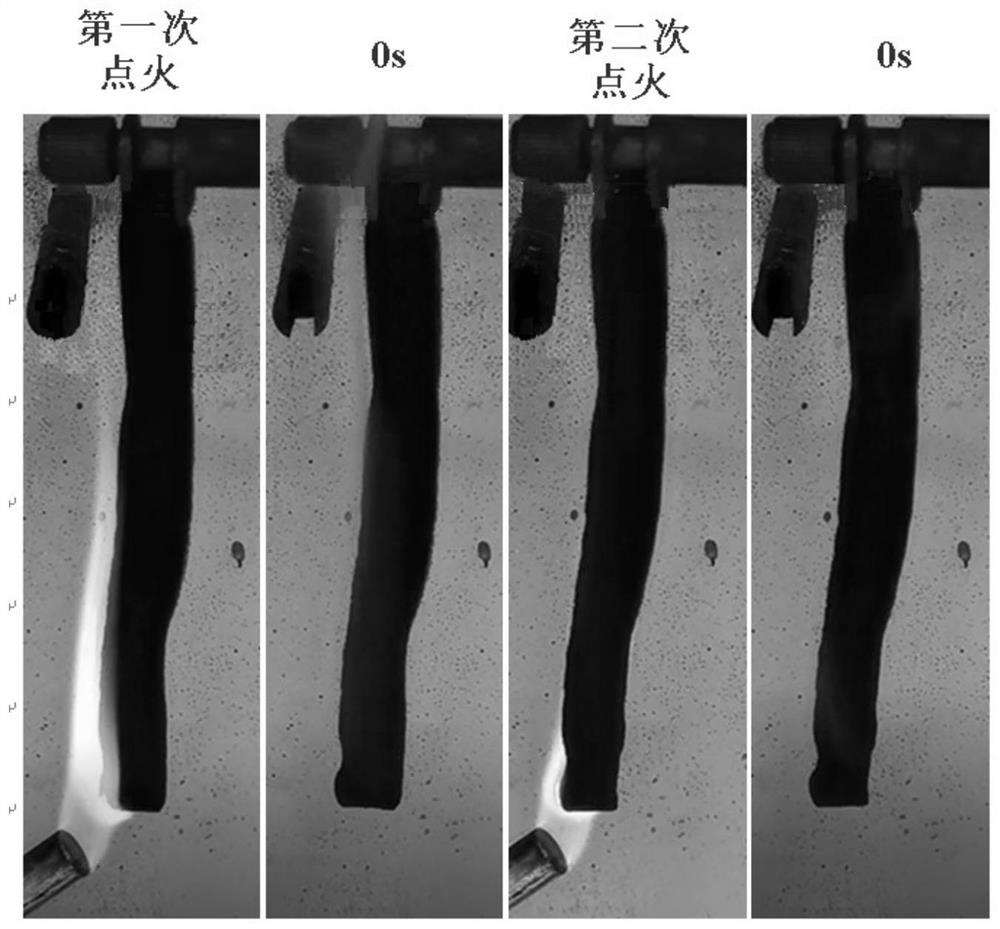

A polyurethane foam and electromagnetic shielding technology, which is applied in the field of polyurethane foam modification, can solve the problems of incompatibility of flame retardancy and electromagnetic shielding performance, destruction of skeleton structure, interruption of conductive network, etc., achieve excellent electromagnetic shielding effect, simple preparation method, Good flame retardant effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0030] A preparation method of flame-retardant polyurethane foam with electromagnetic shielding function, comprising the following steps:

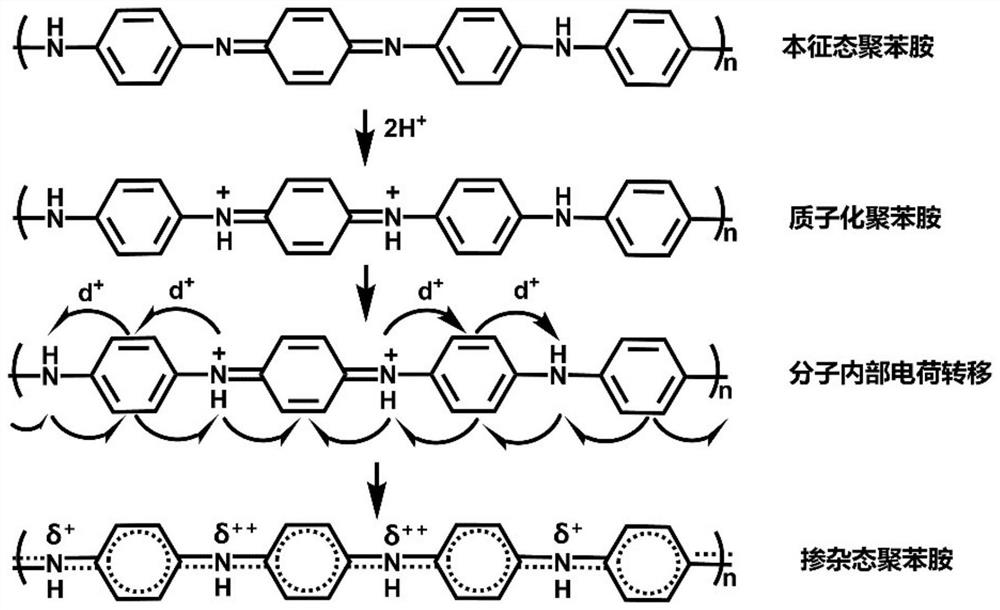

[0031] Step 1: Immerse the polyurethane foam in the mixed solution A, wherein the mixed solution A is obtained by mixing the phosphoric acid solution and the aniline solution, wherein the ratio of the amount of the phosphoric acid-containing aniline in the mixed solution A is 1:10~1.5: 1;

[0032] Phosphoric acid is one of phosphorous acid, phosphoric acid, and phytic acid, or a mixture of two or more of them in any proportion. The molar concentration of phosphoric acid solution is 0.1M~1.0M, and the molar concentration of aniline solution is 0.5M~5.0M; the immersion time is 1~4h, and the immersion is carried out at 0°C under stirring conditions; generally, the mixed solution A solvent uses water or ethanol.

[0033] Step 2: add ammonium persulfate to the mixed solution A in step 1 to carry out in-situ polymerization, fully react to obta...

Embodiment 1

[0039] Step 1: prepare a phosphoric acid solution with a concentration of 0.1M, add an equal volume of aniline solution with a concentration of 0.5M; soak the polyurethane foam in the above mixed solution, stir at 0°C, and soak for 3 hours.

[0040] Step 2: Add ammonium persulfate in portions, wherein the ratio of ammonium persulfate to aniline is 1.3:1, stirring and impregnating at 0°C for 3 hours; after the reaction is completed, wash the polyurethane foam with water and ethanol, and wash it at 100°C Tumble dry.

[0041] Step 3: Place the polyurethane foam treated in step 2 in an ethanol solution of carbon nanotube CNT with a concentration of 20mg / ml, dip-coat it 7 times, and then dry it at 100°C to obtain a flame-retardant polyurethane with electromagnetic shielding function Foam.

Embodiment 2

[0043] Step 1: Prepare a phosphoric acid solution with a concentration of 0.7M, and add an equal volume of aniline solution with a concentration of 0.7M; soak the polyurethane foam in the above mixed solution, stir at 0°C, and soak for 3 hours.

[0044] Step 2: Add ammonium persulfate in portions, wherein the ratio of the amount of ammonium persulfate to aniline is 1.2:1, stir and impregnate at 0°C for 3 hours; after the reaction is completed, wash the polyurethane foam with water and ethanol, and wash it at 90°C Tumble dry.

[0045] Step 3: Place the polyurethane foam treated in step 2 in an ethanol solution of carbon nanotube CNT with a concentration of 20mg / ml, dip-coat it for 6 times, and then dry it at 90°C to obtain a flame-retardant polyurethane with electromagnetic shielding function Foam.

PUM

| Property | Measurement | Unit |

|---|---|---|

| peak heat release rate | aaaaa | aaaaa |

| peak heat release rate | aaaaa | aaaaa |

| limiting oxygen index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com