Automatic conveying device for clamp piece machining

A technology of automatic conveying device and pliers, which is applied in the direction of conveyor control device, conveyor objects, transportation and packaging, etc., can solve the problems of high labor cost for pliers processing, low processing efficiency of pliers, and increased safety hazards, etc. Achieve the effects of improving the processing efficiency of the pliers, reducing labor intensity and labor costs, and improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

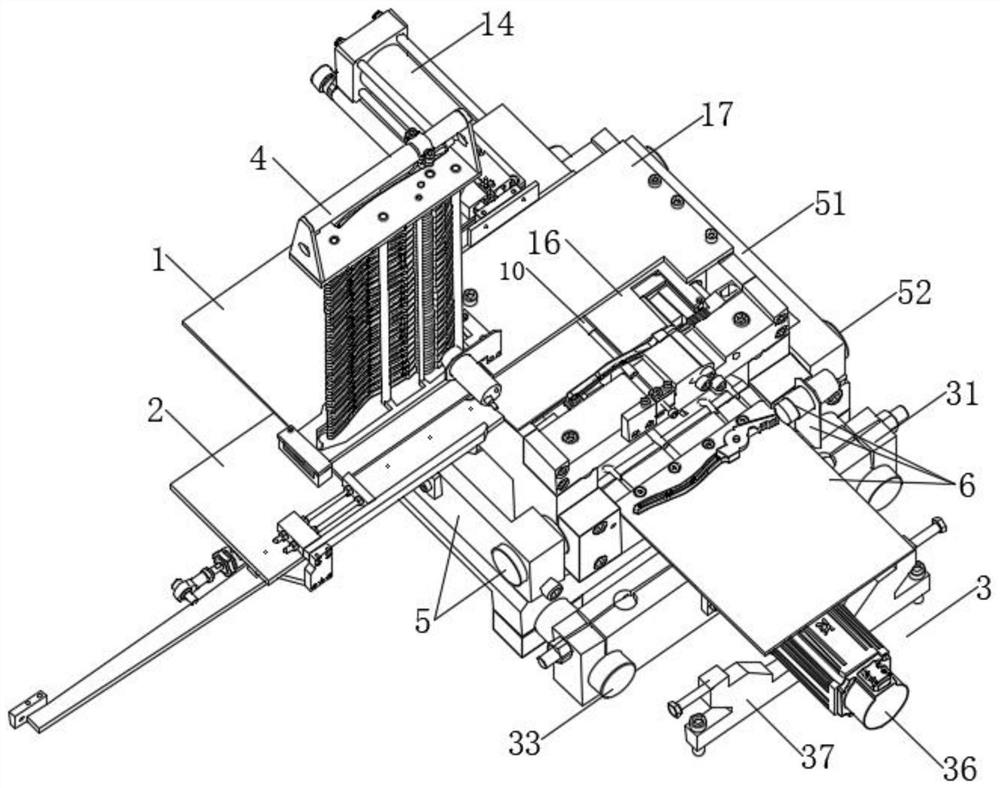

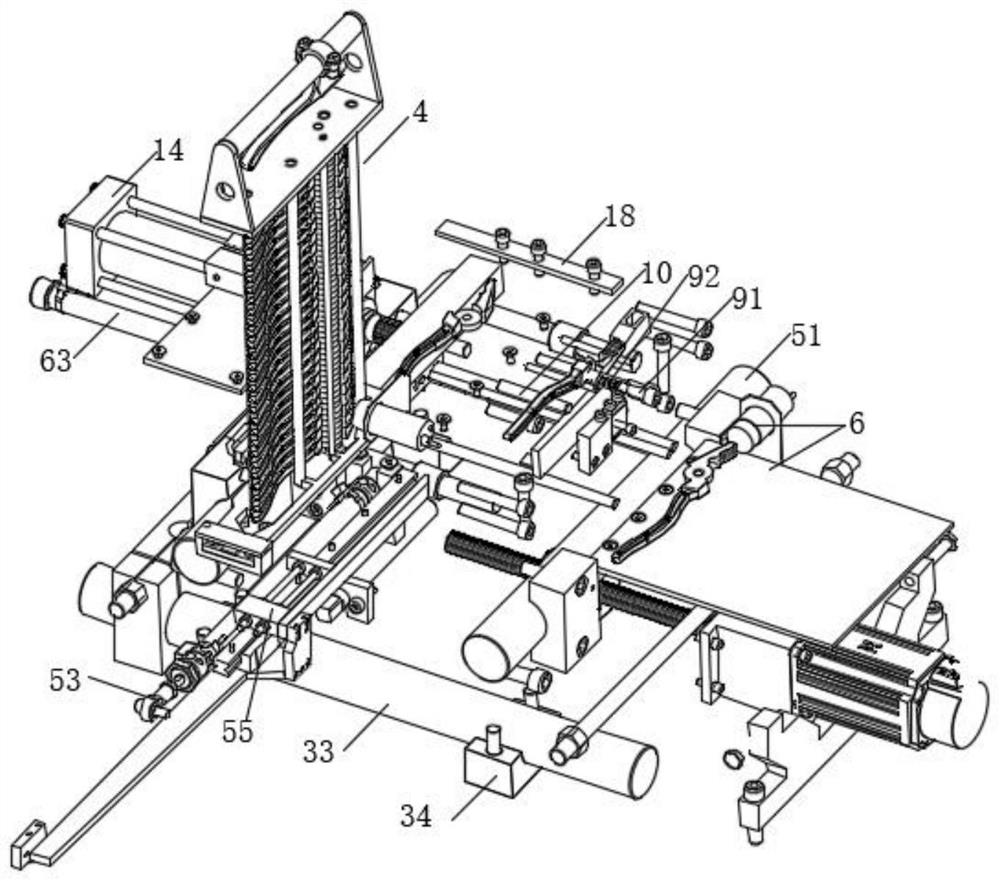

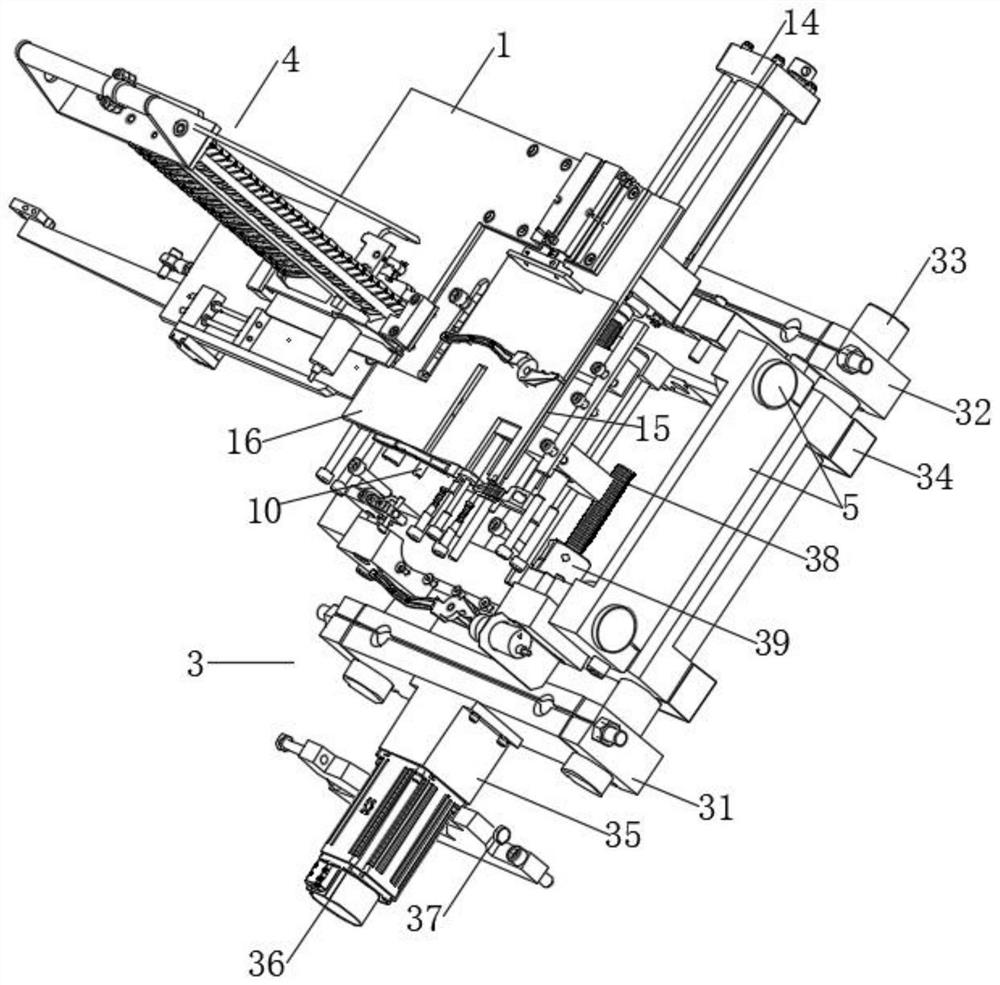

[0024] Such as Figure 1-6As shown, this specific embodiment adopts the following technical solutions: an automatic conveying device for pliers processing, including a manual discharge device 1, a primary moving seat 3, a material collecting device 4, a secondary moving seat 5 and a discharge mechanism 6 , one side of the manual discharge device 1 is equipped with a feeding base plate 2, a first-level mobile seat 3 is provided below the manual discharge device 1, and a collection device 4 is provided on the top of the manual discharge device 1, so The top of the first-level mobile seat 3 is provided with a secondary mobile seat 5, and the side of the secondary mobile seat 5 away from the material collecting device 4 is provided with a discharge mechanism 6, and the top of the secondary mobile seat 5 is close to the discharge mechanism. One side of the 6 is fixedly installed with an integrated fixed clamp block 7, and the side of the integrated fixed clamp block 7 close to the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com